Prevent Tap Breakage in Alloy Steels

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

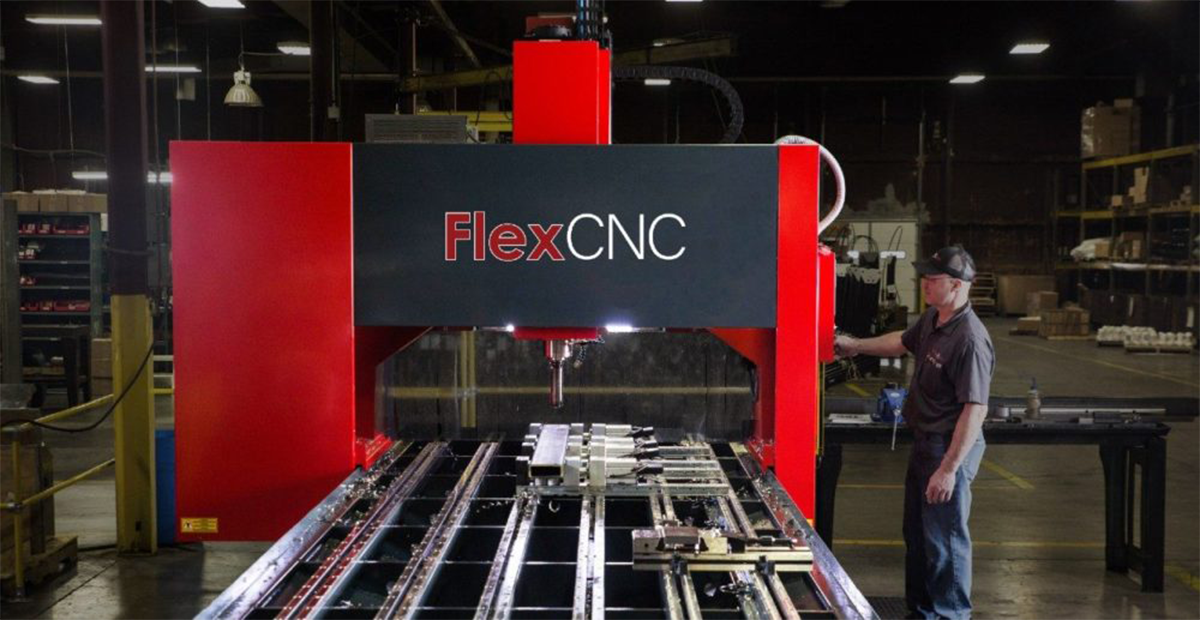

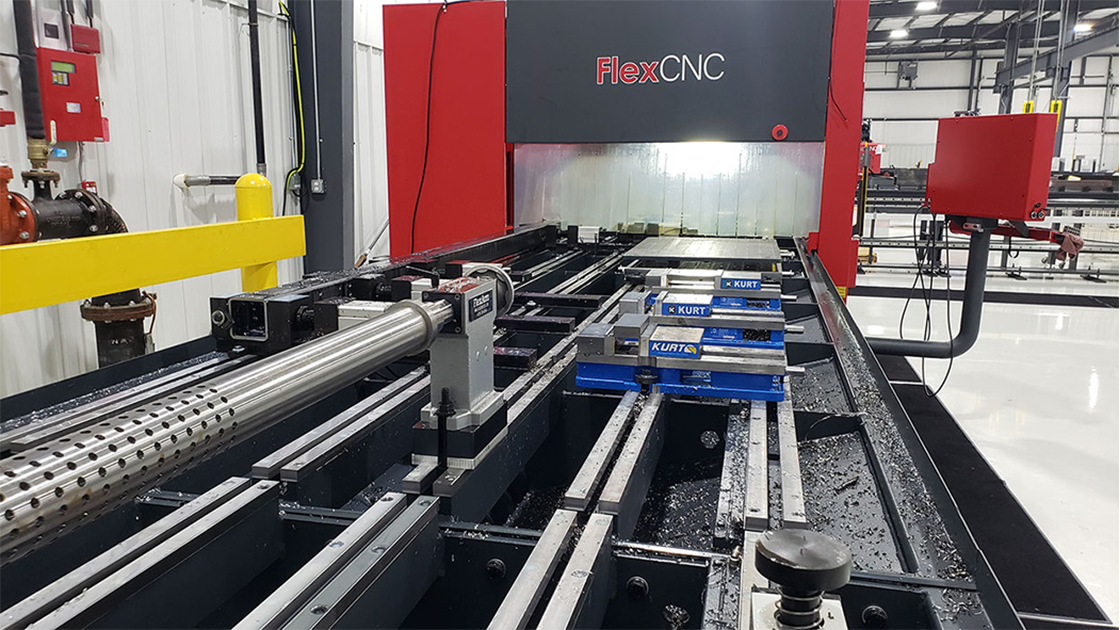

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

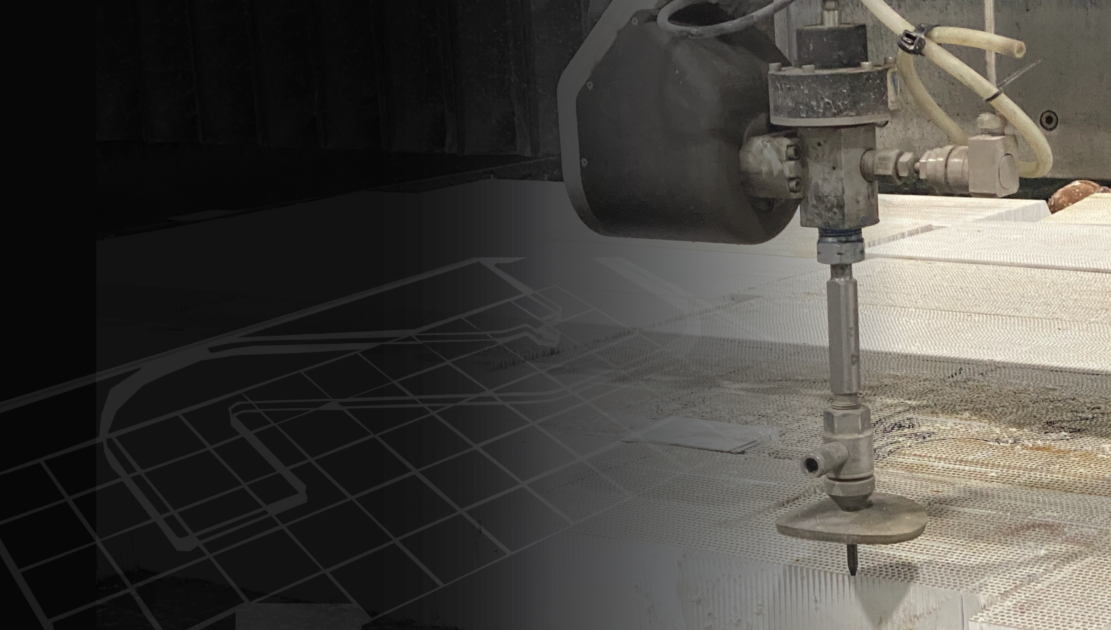

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

Today, US manufacturing is widely misunderstood, especially among young people. Manufacturing remains central in the world economy yet is seen as an outdated and dying

Richard Kennedy launched Midwest Specialties, Inc., in 1971 as a government contracting manufacturing business. He designed and built a tapping arm to increase speed and

Eliminating Spindle Downtime Imagine being able to machine a bunch of different parts in one machining center without ever stopping the spindle. I know what

John Saunders, a.k.a. “NYC CNC,” is the guest for this week’s episode of Fireside Chats. During this interview, we discuss a variety of different topics,

WATCH FULL CUSTOMER STORY BELOW In the fabrication industry, staying ahead of your competitors is always crucial. With continued technological advancements, businesses need a well-rounded

Installing threaded inserts by hand can be time consuming and inaccurate. One of our customers faced this problem when it came to installing inserts into

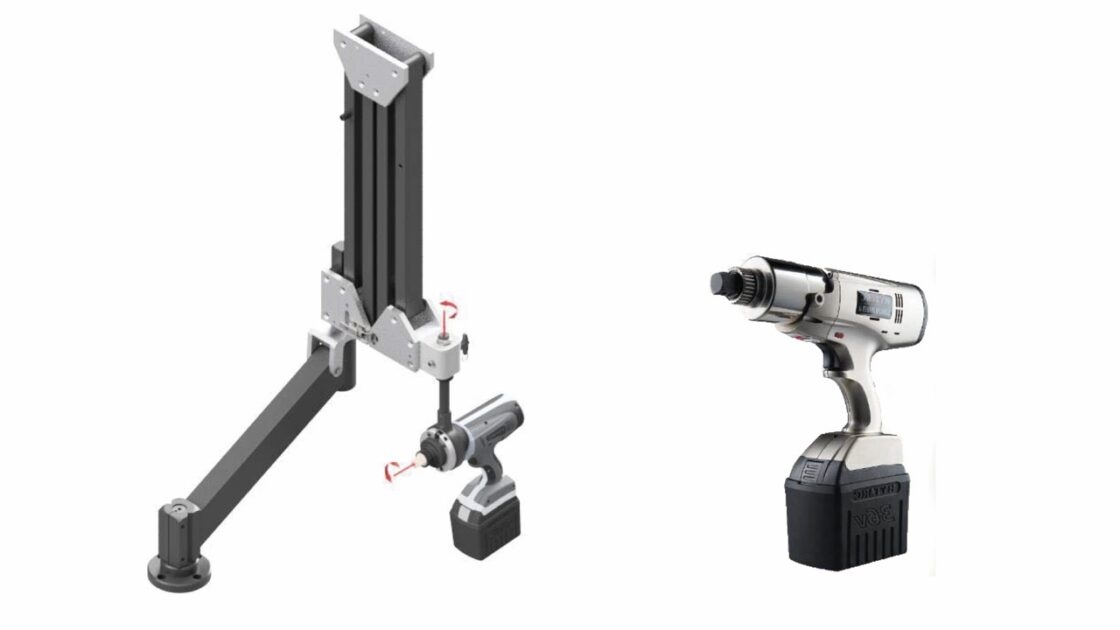

The Problem with Heavy Tools Bolting applications often require heavy tools such as torque wrenches and impact wrenches to achieve the appropriate level of tightness

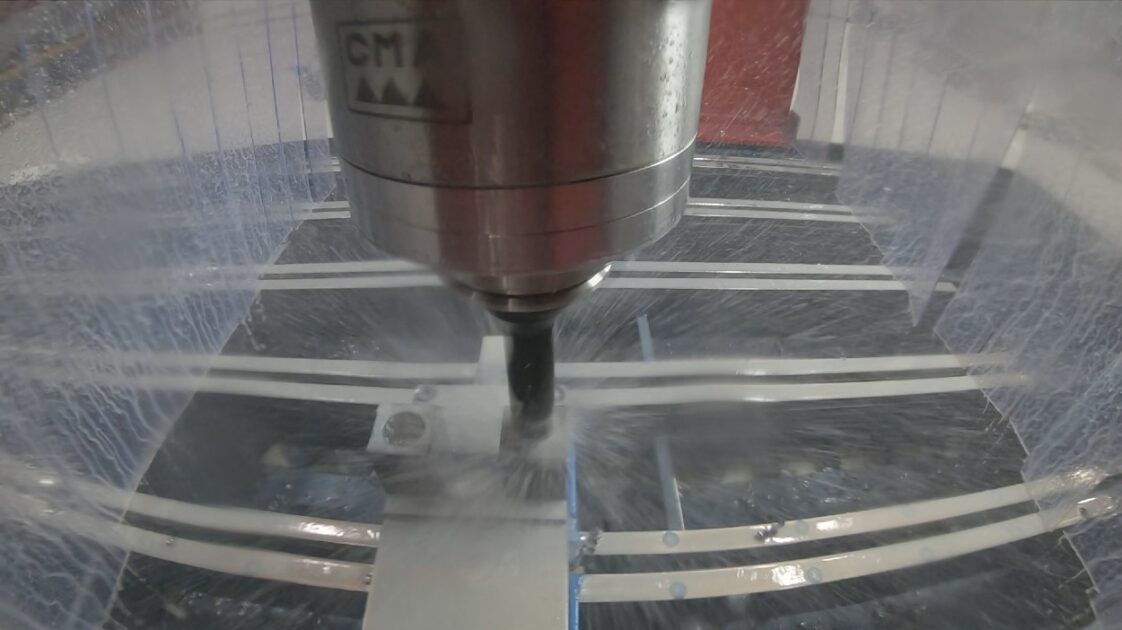

Watch the video of this time study at the bottom of the page Using a CNC Machining Center to drill is safer, faster, and more

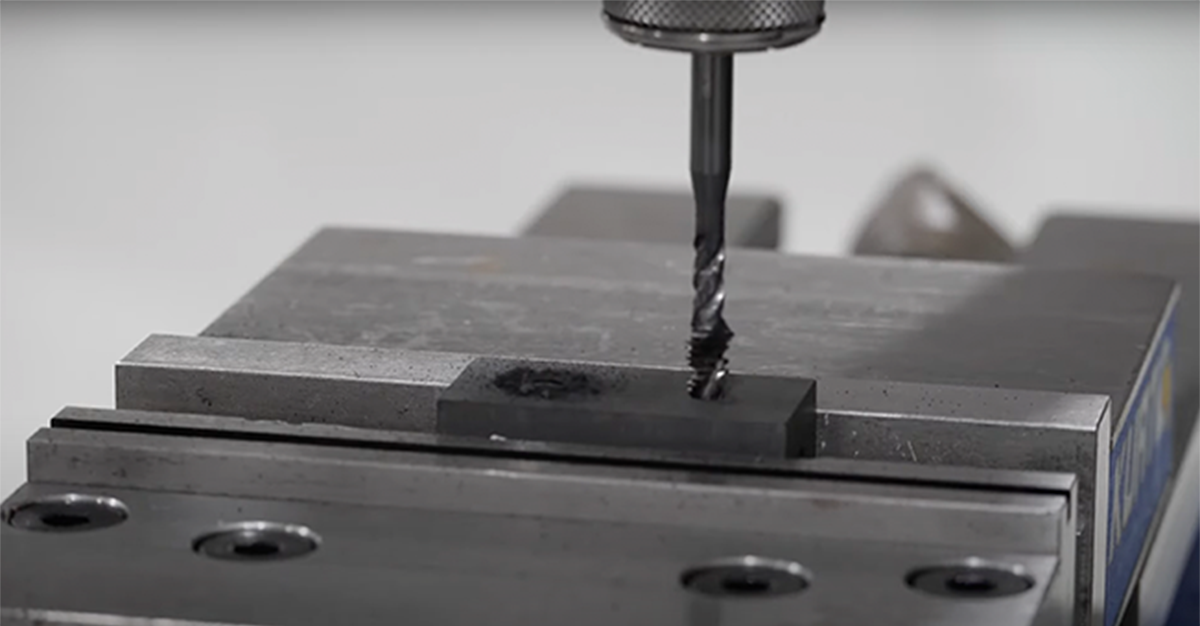

Tapping small holes can be a challenge. You are guaranteed to break taps whether you tap by hand, with a cordless drill, or in a

HOW TO TAP GRAPHITE? Tapping graphite, a notoriously soft and brittle material, presents a significant challenge. Finding reliable information on how to tap graphite is

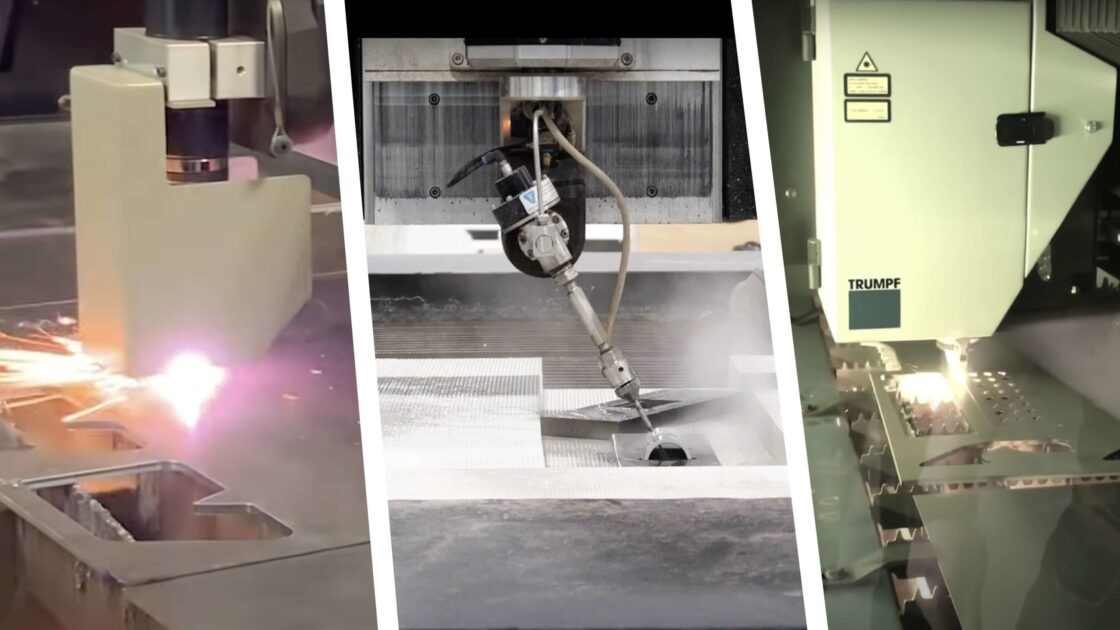

The Challenge of Tapping Holes Created by Laser, Plasma, and Waterjet Cutting Machines If you work in a fabrication shop, you are probably familiar with

HOW TO THREAD REBAR? Rebar is found in nearly every concrete and masonry structure in the United States. Global Market Insights reports that the United States produced

Throughput is the number one metric for assessing the quality of a production line, and increasing throughput on a CNC means increased profitability. Flex Machine

What’s your why? What’s your strategy? These are two key questions you should be asking yourself when marketing in the manufacturing industry. Too many people

Lindsay Machine Works, Inc. has owned a FlexArm for 15 years. They recently purchased a hydraulic arm to handle larger tap capacities. See how many holes they can

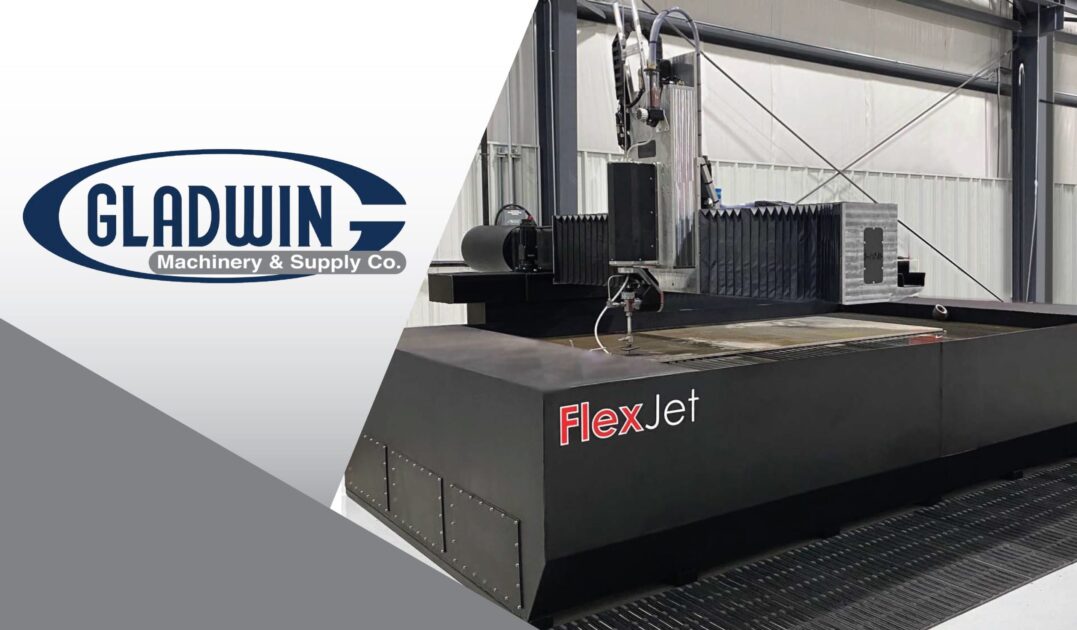

Flex Machine Tools is happy to announce Gladwin Machinery as the newest distributor of the FlexJet Waterjet. Gladwin has been a strong partner for Flex since 2019,

Learning the Basics of CNC Machining CNC machining can be intimidating. Especially for people who’ve been doing manual machining for years. Understanding the G-code and

Tube lasers are incredible pieces of machinery. They’re fast, precise, and can handle a wide range of materials, including round, square or rectangular tubes, flat

Fabricators looking for a way to increase efficiency and speed up operations can achieve this with the FlexCNC. The long bed allows for the machining

Shops are always on the lookout for ways to continually improve the way they operate. Decreasing cycle times and scrap rates can help save costs

The machines you use to run your business must be kept in good working condition. Failure to do so could end up costing you in

Live Streaming Info is Below FlexArm has collaborated with Launcher, a startup based in New York City, to help them develop the world’s most efficient rocket

The tool and die maintenance and repair department at Ford Motor Co.’s Woodhaven, Mich., plant sought a more efficient and speedy way to perform die

FlexArm Counterbalances Heavy Aircat Impact Wrench The FlexArm engineering team recently designed a custom solution to counterbalance an Aircat 1994 1″ Superduty Impact Wrench. The tool

We are happy to announce Landmark Solutions as the newest distributor of FlexCNC and FlexBeam in the West. Landmark is based out of Orange County, California, with coverage throughout

FlexJet powered by IGEMS CNC and CAD/CAM software is a collaboration between Ohio-based Flex Machine Tools and IGEMS of Sweden. The FlexJet will be integrated with the

Flex Machine Tools is excited to announce the launch of its newest waterjet cutting system, the FlexJet FLX. This innovative machine is designed to meet the

FLEX MACHINE TOOLS IS TEAMING UP WITH ABOM79 AND ALLIED MACHINE & ENGINEERING FOR AN INTERACTIVE LIVE STREAM DEMO. Watch as we drill 4” deep

The FlexCNC is a vertical machining center offered by Flex Machine Tools. Below are five of the many features that set this machine apart from