FlexCNC: An Affordable Alternative to Tube Lasers

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

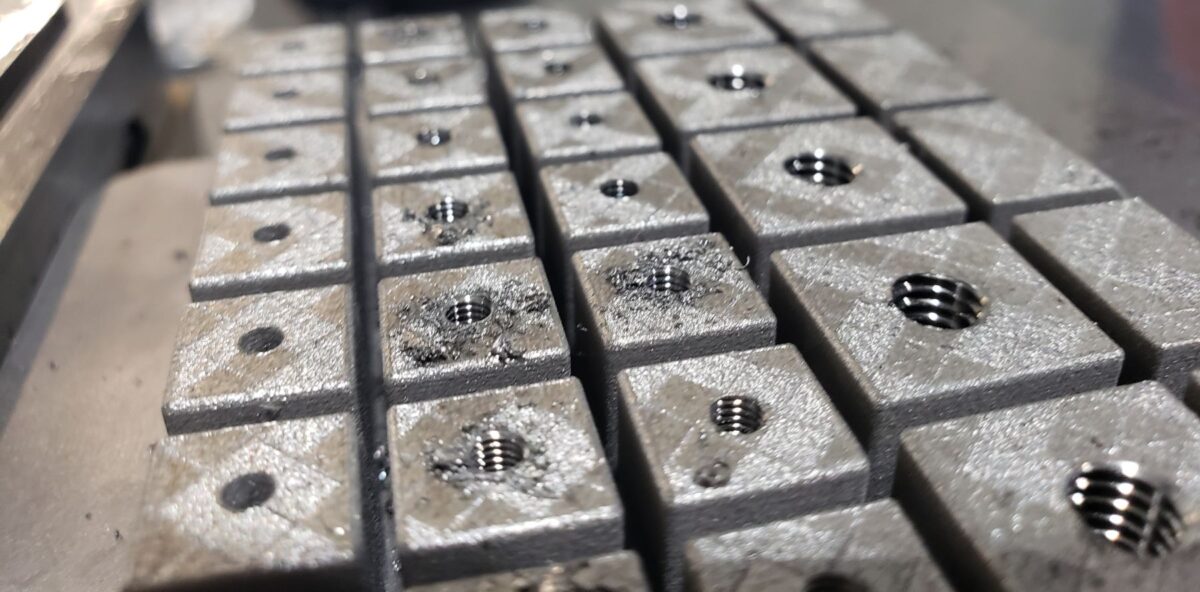

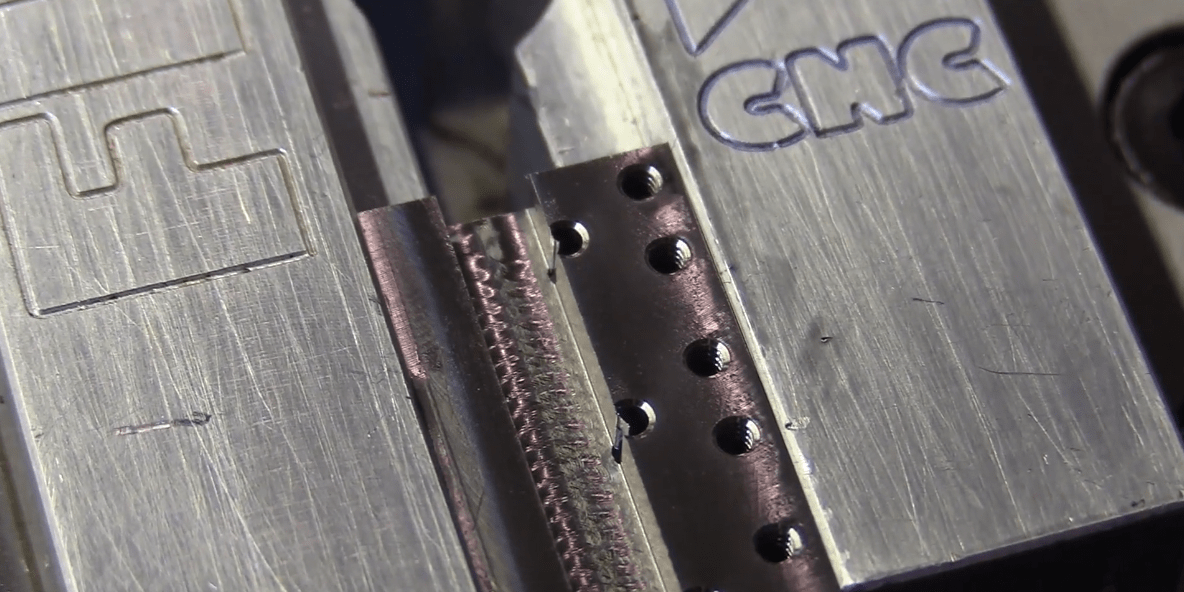

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

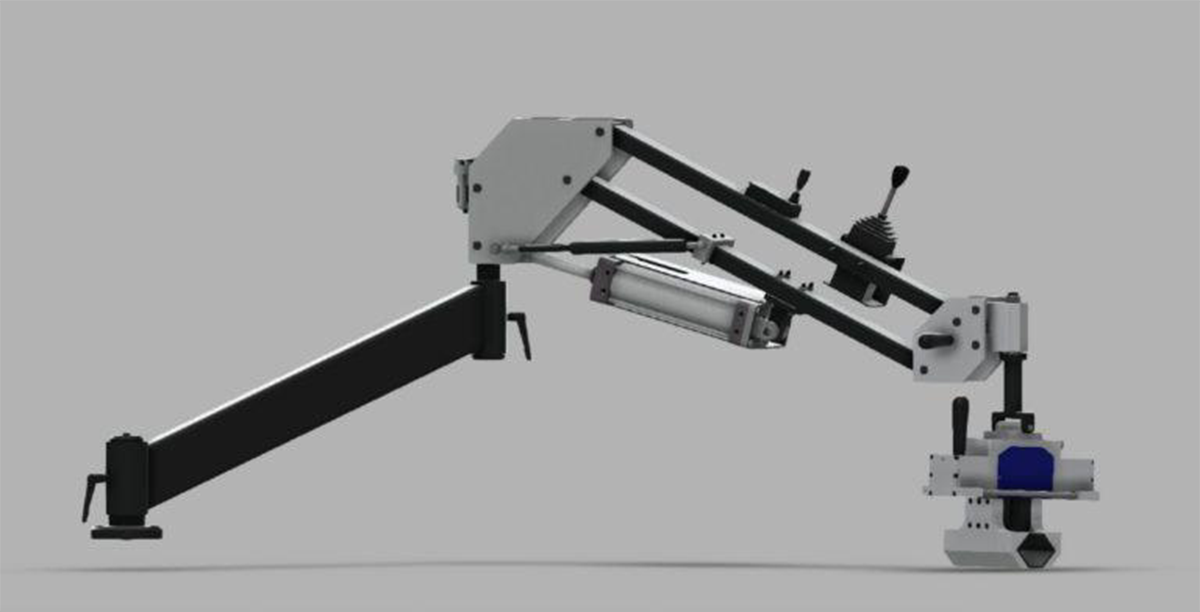

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make

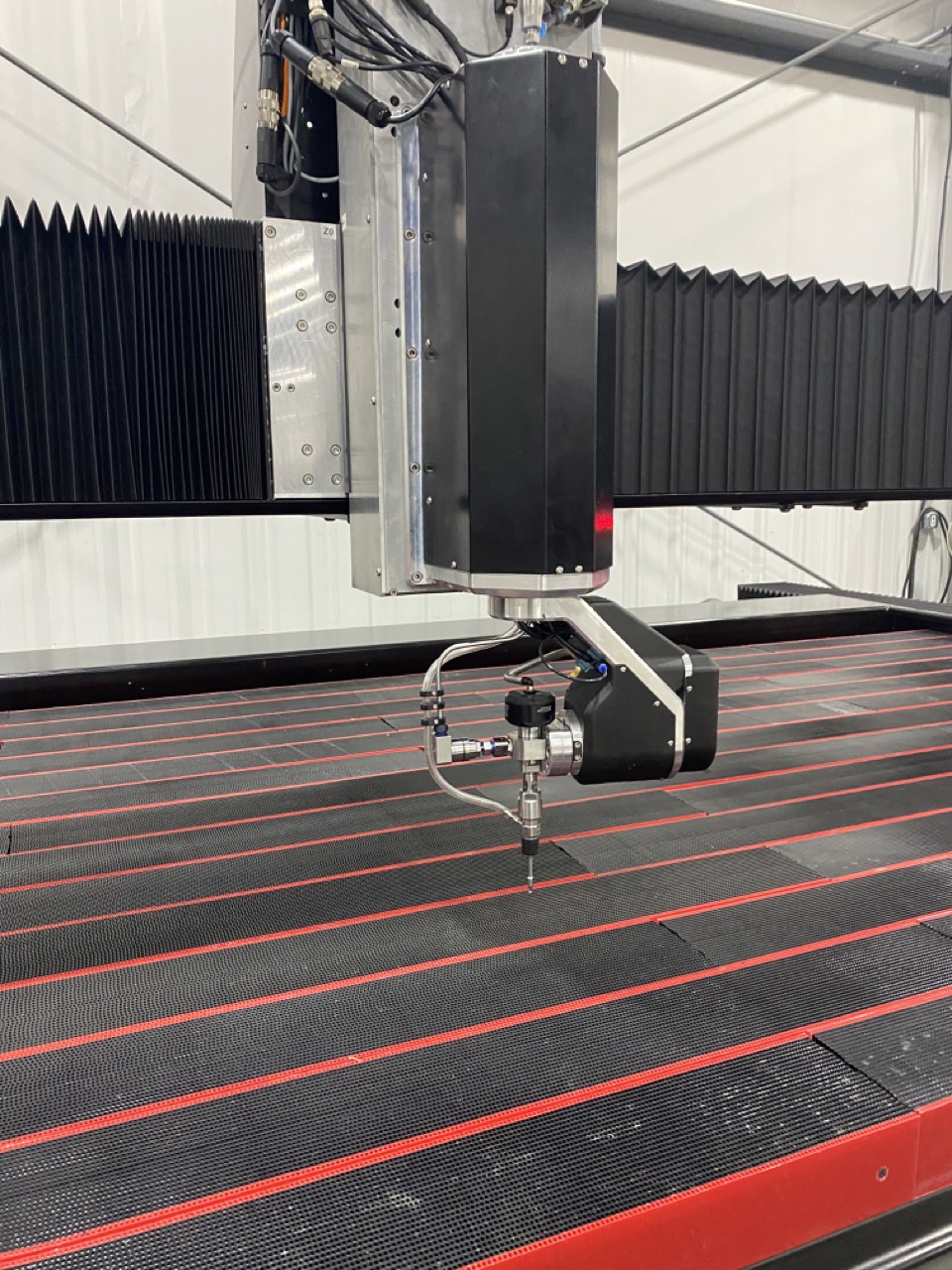

All FlexJet models come with a multitude of customizations, including the type of cutting head. The waterjet cutting head you choose can depend on many

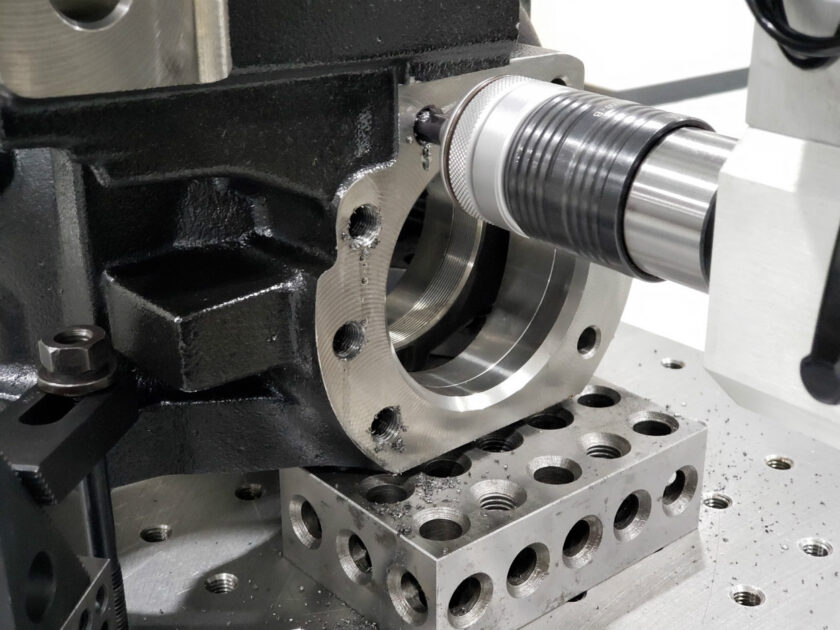

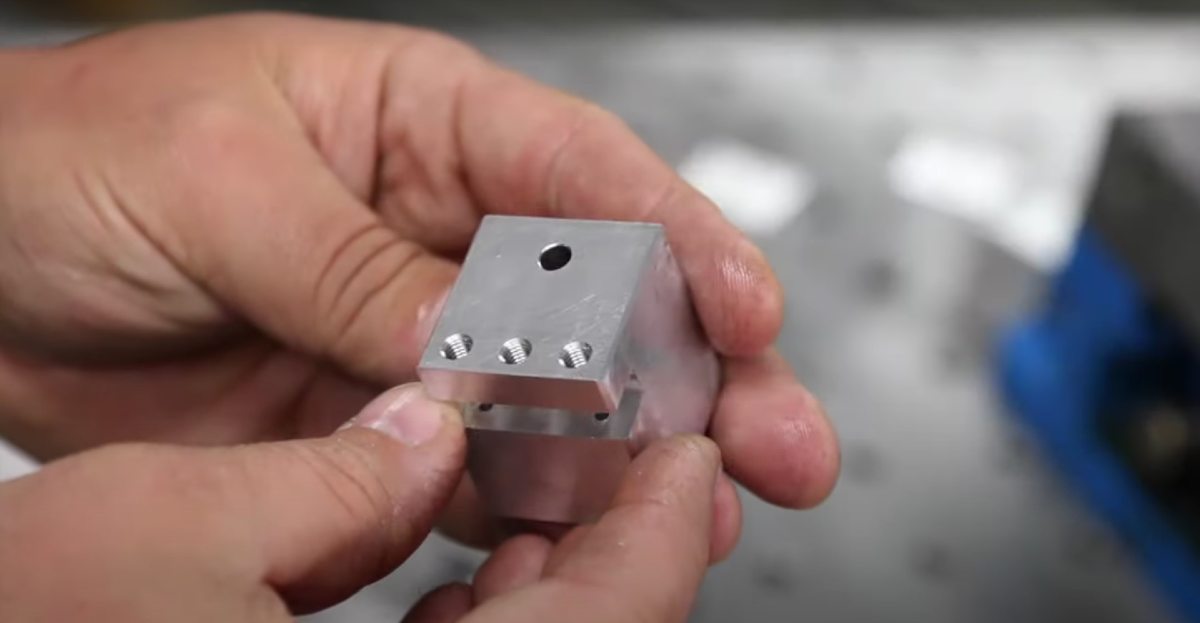

Maintaining tight tolerances is critical for delivering quality parts, reducing scrap, and avoiding costly rework. Even the best machining centers can struggle to hold tolerances

Waterjet cutting is one of the most versatile and precise material processing technologies available today. Whether you’re cutting metal, plastic, glass, or composite materials, waterjet

As published in The Fabricator on March 25, 2025. View article here. Perhaps you are investigating a significant machine tool investment and weighing the options

March, 2025- With a business model based on the aspiration to do everything from project concept to implementation, Fulcrum Technologies Inc. wanted to become more

In the world of CNC machining, choosing the right tooling and setup for your application can significantly impact efficiency, precision, and cost. Two powerful options

In manufacturing, productivity and efficiency are core concepts often misconstrued or used synonymously despite their importance to improving company throughput. Knowing the differences and intricacies

Waterjet cutting is a manufacturing process that uses highly pressurized water, sometimes with an abrasive, for an accelerated eroding process that can cut and shape

Is repetitive lifting causing backaches, fatigue, and injuries in your manufacturing facility? This can lead to a revolving door of employees, costing you time, money,

The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC

Flex Machine Tools is excited to launch a new product that will revolutionize your workshop: the Flexible Tapping Center (FTC). This specialized machine is equipped

When selecting machinery for your company, deciding what tools will work best for your product can be overwhelming, and it can feel like a risk

Working with heavy tools like the Metabo KFM 16-15 Metal Beveling Tool can be physically demanding. Constant tool weight leads to fatigue, accidental drops, and

Active Alloys is a full-service steel fabrication shop in Chicago, Illinois. They specialize in designing and fabricating architectural elements, machines, furniture, and vehicles. William Tellmann and

Safety is of the utmost importance when operating heavy machinery, especially when it comes to press brakes. The large, heavy parts involved, can easily cause

An end-user out of Indiana was interested in taking their tapping operations offline. They offer CNC services for customers in the automotive, heavy truck, and

If you can imagine it, a waterjet will cut it. Who uses a waterjet cutting system? Waterjets are one of the most versatile cutting machines

What is a Beam Drill Line? Beam drill lines are important tools in medium to large-sized structural fabrication shops. Beam drill lines accurately drill holes

Flex Machine Tools partners with Westway Machinery We are pleased to announce that Flex Machine Tools has entered into a distribution partnership with Westway Machinery. Westway

Waterjet or laser? Many modern manufacturers are facing unique challenges, including maintaining flexibility while keeping costs low. The waterjet and the laser are both capable

If you’re a fabricator new to CNC technology, you may be wondering where to start when purchasing the right machinery for your needs. Two popular

Watch the video of this application at the bottom of this page. We had a customer looking for a torque reaction solution that could counterbalance

Torque Reaction Arms or assembly arms are commonly used in a variety of manufacturing environments. They take the tool weight and torque out of the operator’s

Watch the video of this application at the bottom of this page. We had an end-user out of California interested in seeing if the FlexArm

Tangible Solutions out of Fairborn, Ohio recently contacted us wanting to see if a FlexArm could handle tapping their small parts. They make 3D-printed titanium

Tapping can be challenging and frustrating, especially when broken taps and damaged threads come into play, leading to lower productivity and increased costs. However, various

Located in Valparaiso, Indiana, RockRabbit Guitars manufactures premiere guitar parts made of titanium. One of these parts requires 18 threaded holes. Up until recently, the

An end user recently approached Flex facing a common challenge: tapping plasma cut holes in A36 Steel. This particular end user is a general fabrication

Brad Jacob, from the BasementShopGuy YouTube channel, tested the FlexArm tapping arm against the Bridgeport in a time comparison demonstration. He wanted to see if the addition of a