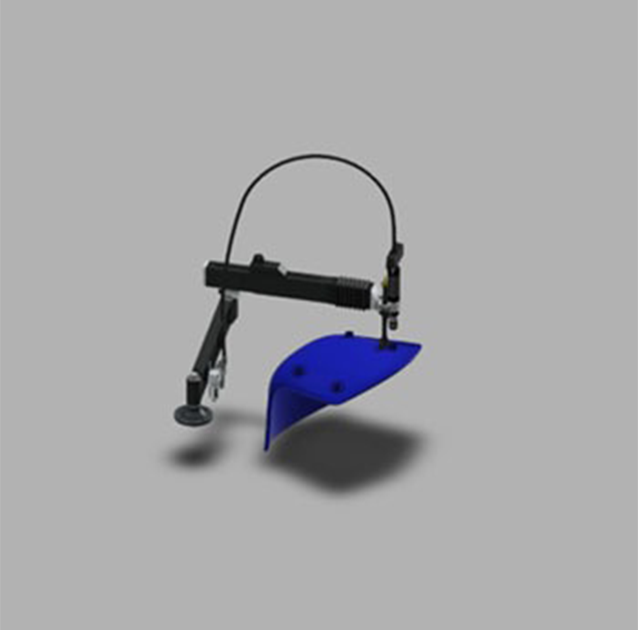

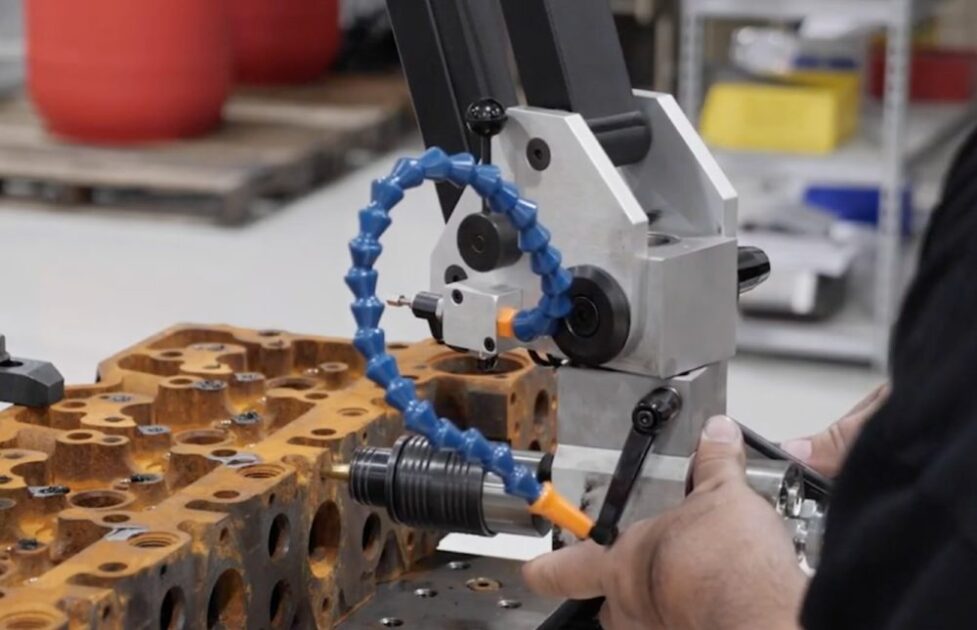

Take the Risk Out of Choosing Tapping Arms:

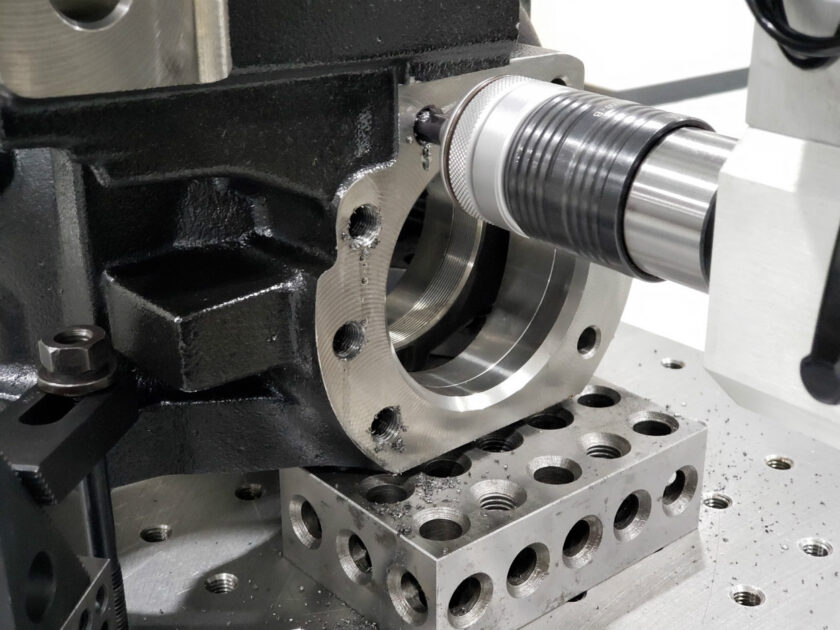

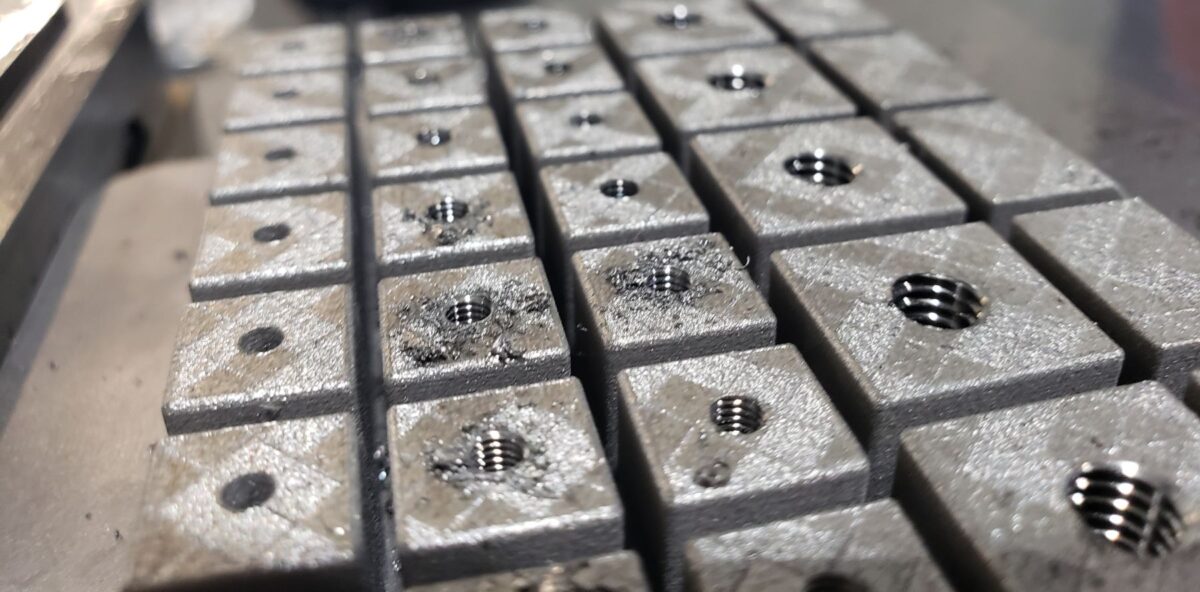

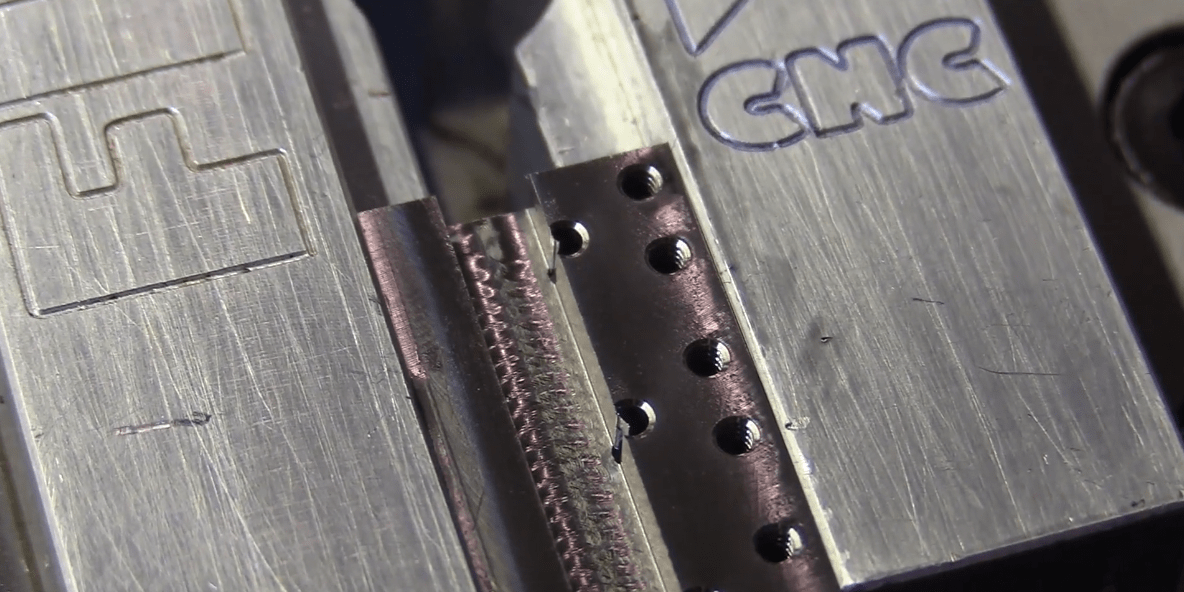

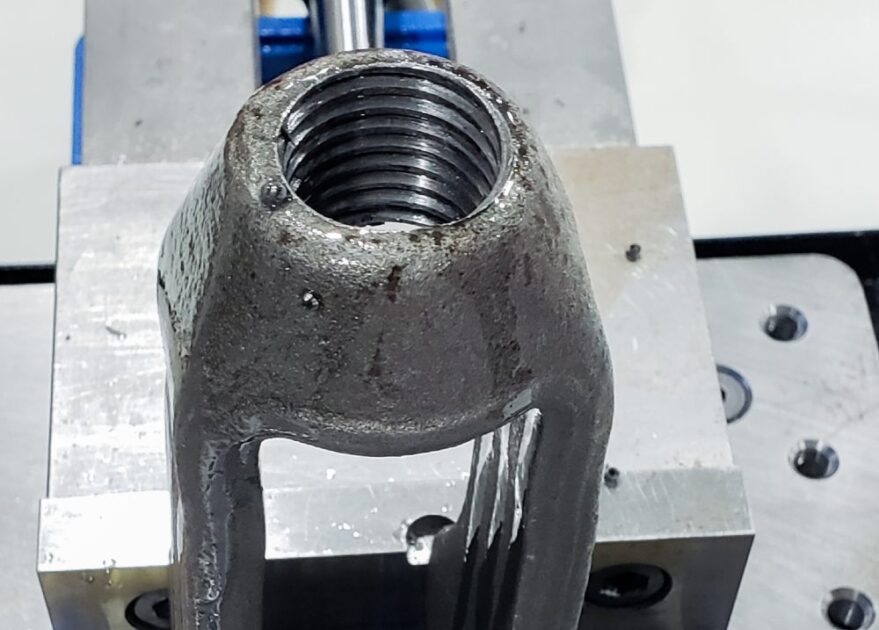

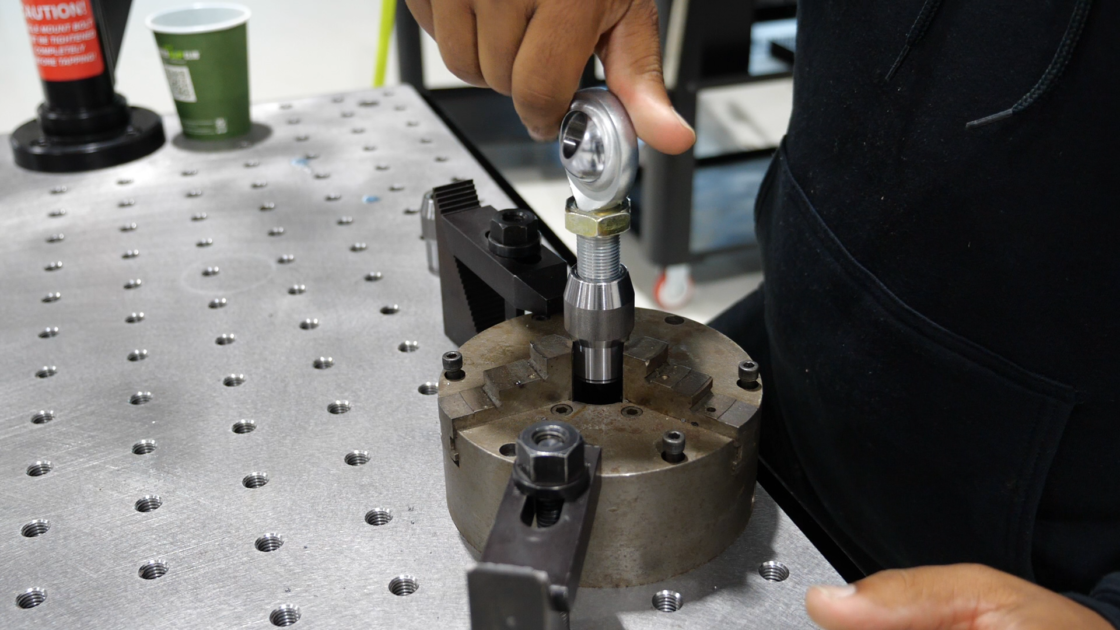

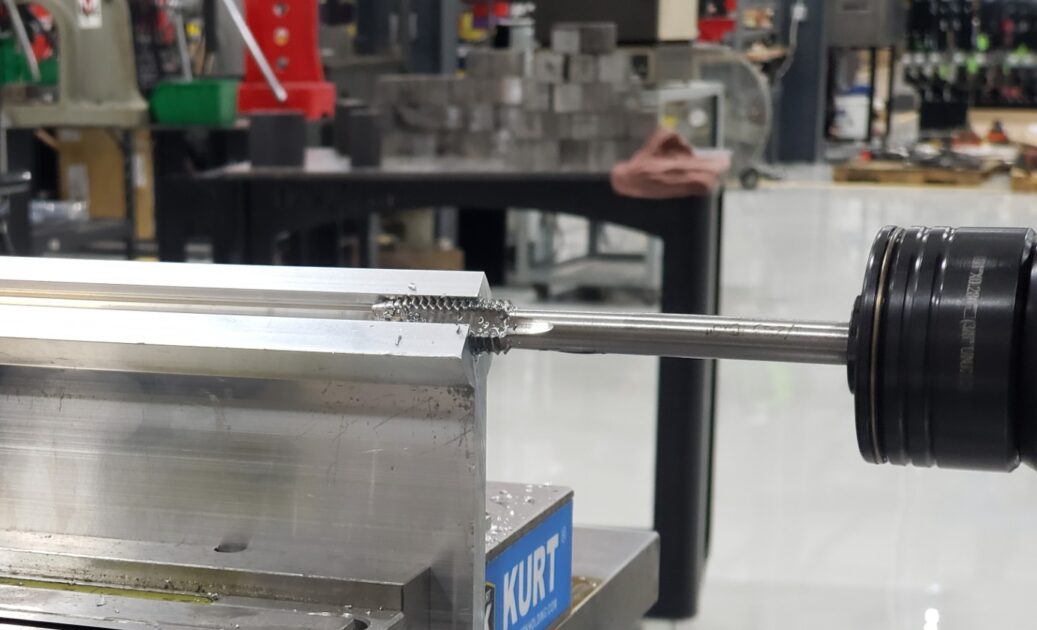

Free Tap Test by FlexArm

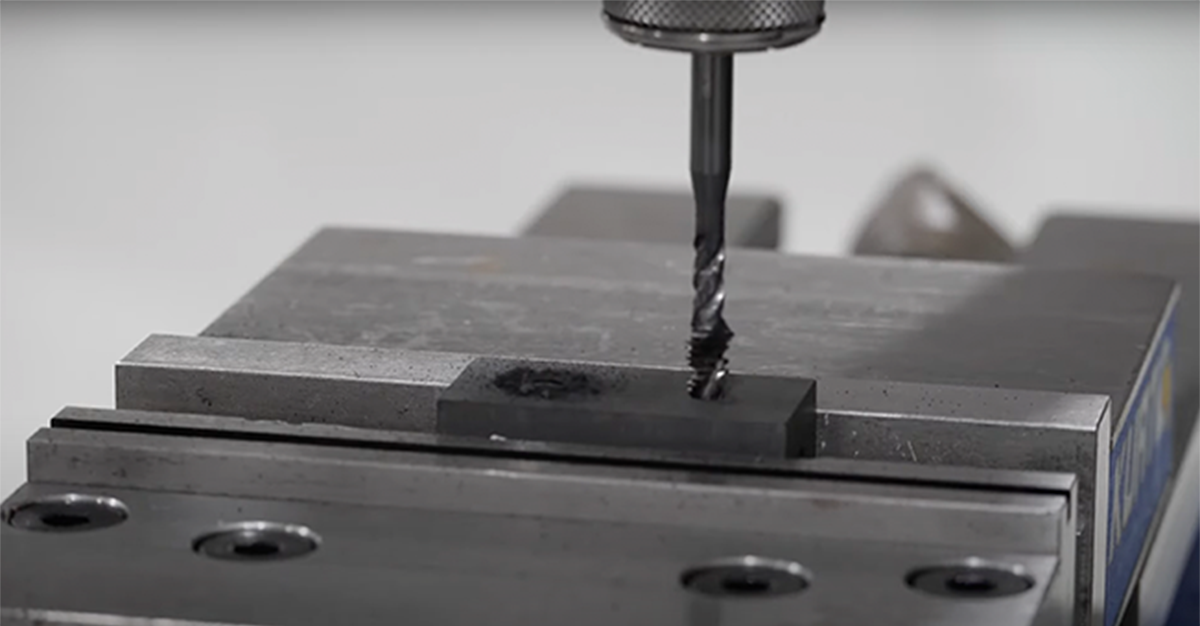

When selecting machinery for your company, deciding what tools will work best for your product can be overwhelming, and it can feel like a risk