HOW TO THREAD REBAR?

Rebar is found in nearly every concrete and masonry structure in the United States. Global Market Insights reports that the United States produced over 7 million metric tons of rebar just in 2018 alone. Threaded rebar is often used, but currently, there are limited options to quickly and easily thread rebar. However, the FlexArm can handle even the most challenging threading and tapping applications.

At Flex Machine Tools, we like to find tapping solutions for almost any tapping application. When a company came to us looking for a quick and easy solution for threading rebar, we jumped at the opportunity to test a material that hasn’t yet been tested on a FlexArm.

Getting threads onto the ends of rebar can be challenging, and only a limited number of companies are capable of doing this. The irregularities of surface finish, softness, brittleness, and length of the material makes the threading process difficult for even a master machinist. Our goal was to show the end-user the wide-ranging capabilities of the FlexArm.

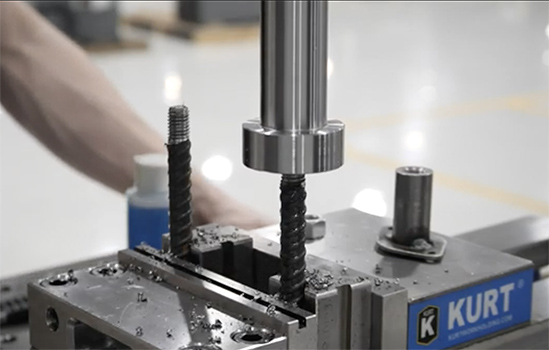

For this tap test, we chose the GHM-24 with a quick-change die holder. The multi-position head (signified with the ‘M’ in GHM) is an excellent option because it allows the user to easily tap the ends of rebar by simply adjusting the multi-head to the horizontal position.

The threading process went as expected. The FlexArm quickly and efficiently threaded the material. It was as easy as lining the die over the rebar and pressing the button. After checking the threads, we confirmed that the FlexArm is an appropriate tool to create external threads in such challenging material.

If you are experiencing any similar problems or just looking to speed up your tapping process, give us a call at 1-800-837-2503 or schedule a tap test today.

Watch the videos of the rebar threading process below.