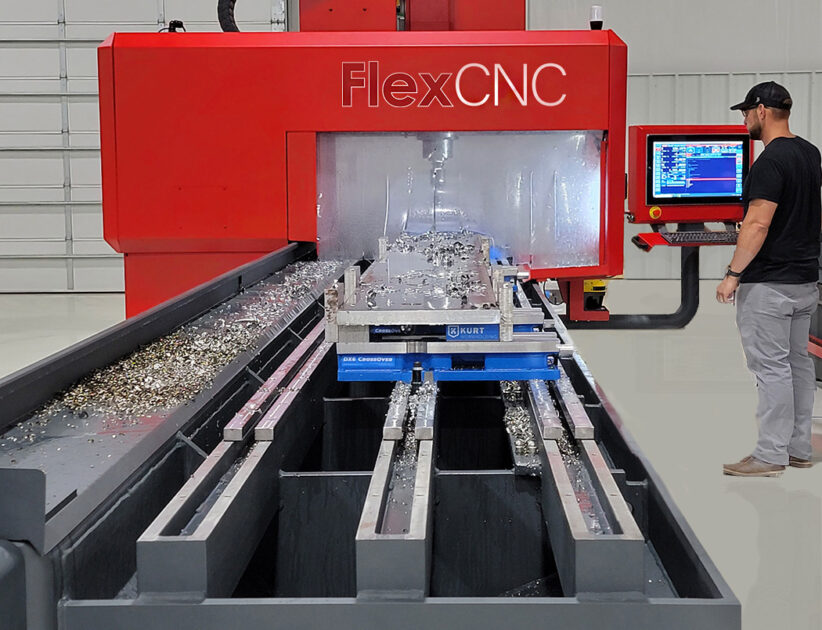

Mastering Waterjet Cutting: An Introduction to Precision and Versatility

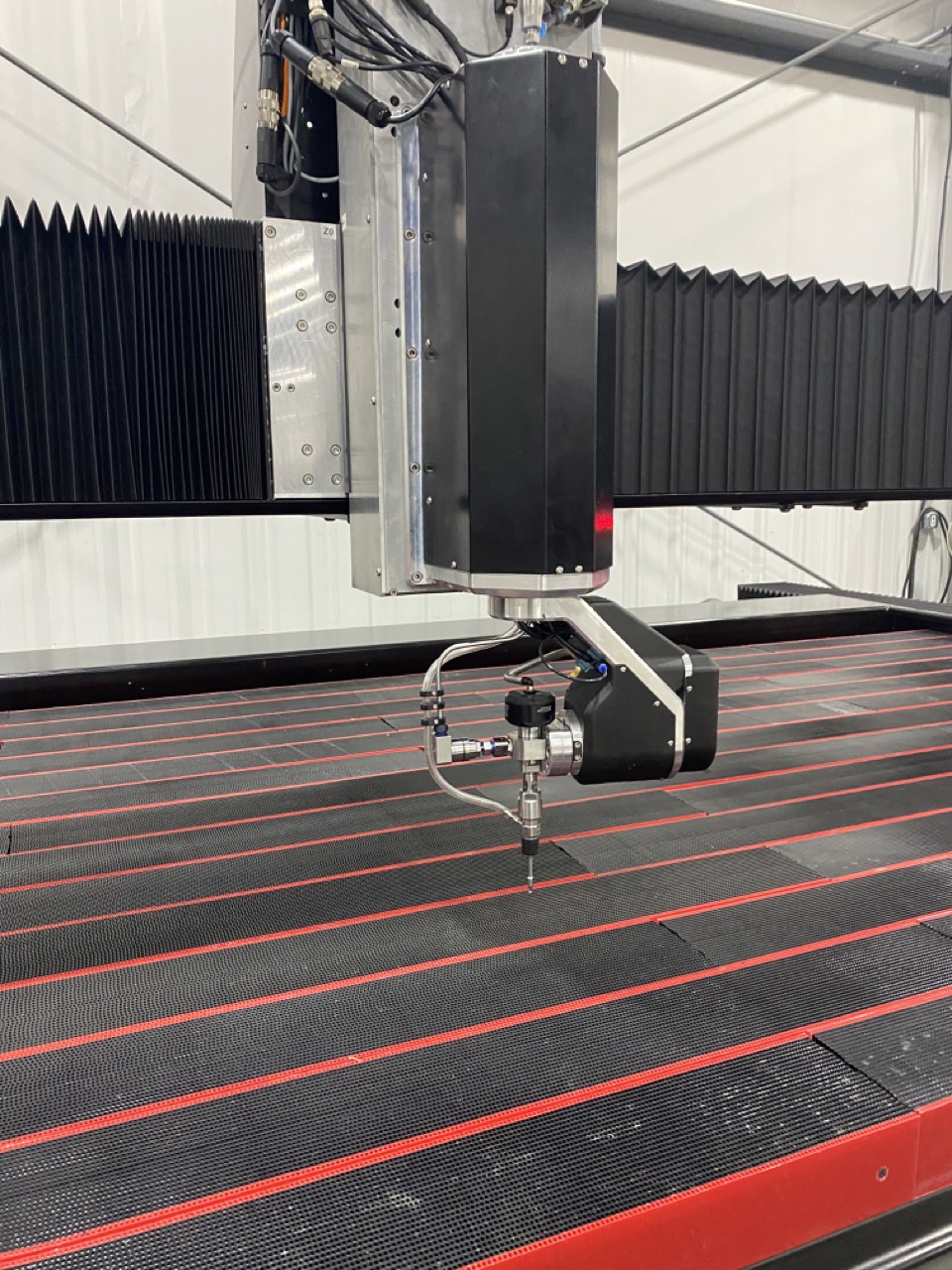

Waterjet cutting is one of the most versatile and precise material processing technologies available today. Whether you’re cutting metal, plastic, glass, or composite materials, waterjet