Flex Machine Tools is excited to introduce a new offering to its line of ergonomic balance arms: the FlexArm B-33. The B-33 Zero-Gravity Balance Arm is a larger model of the FlexArm B-19, both designed for counterbalancing the weight of tools. The B-33 has a longer reach and greater counterbalance weight capacity. This model is excellent for customers who are looking for an ergonomic balancing solution with maximum range and flexibility.

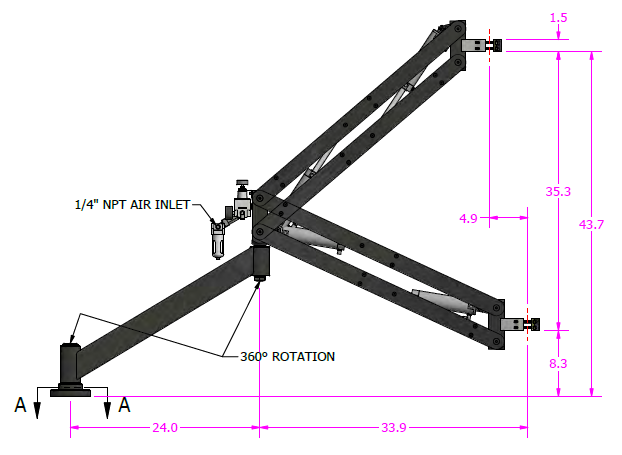

This balance arm has two areas of 360° rotation, allowing it to operate freely on multiple planes: top-down, in and out, and left to right. The standard B-33 is available with a vertical v-block tool mount or with a rotational gimbal (B-33-RG), which adds the advantage of rotating the attached tool during use.

The B-33 with vertical v-block tool mount has a counterbalance capacity of 1-40lbs, a 10”-53” working range, and the v-block fits tool diameters of 1.00″ to 2.25″.

Both versions of the B-33 have a precision air regulator that controls the counterbalancing, making it easy to switch between tools of different weights with a twist of the knob. Shown below are the counterbalance weights with corresponding PSI for the B-33 with vertical v-block.

COUNTERBALANCE WEIGHT: B-33 Vertical V-Block

40 LBS | | 103 PSI |

35 LBS | | 90 PSI |

20 LBS | | 60 PSI |

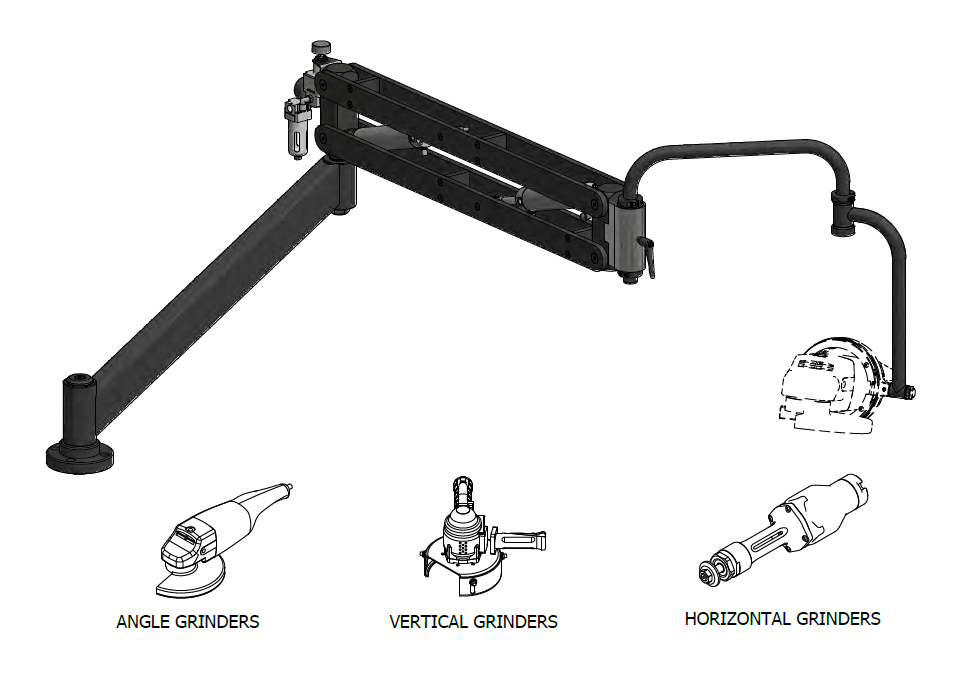

The B-33-RG with rotational gimbal adds even greater reach and the advantage of being able to rotate the tool during use. The counterbalance capacity is 1-25lbs and the arm has an impressive 72” working range. The rotational gimbal on the B-33 is great for counterbalancing angle grinders, vertical grinders, and horizontal grinders. This version of the B-33 can counterbalance up to a 25lb tool at 105 PSI and provides complete freedom of motion. The large selection of gimbal options can fit tool diameters from 0” to 5.375” and most vertical grinders. The clamp plates for each rotational gimbal are made specific to the tool body profile for a secure hold.

The FlexArm B-33 Zero-Gravity Balance Arm offers the greatest reach and counterbalance weight capacity of any FlexArm balance arm. For those who need this additional range, or those looking for a versatile balance arm with customizable mounts, the FlexArm B-33 balance arm is right for you! Contact us today or give us a call at 1-800-837-2503.