In the world of metalworking, precision and efficiency are paramount. Threading holes accurately and consistently is essential for ensuring the integrity and performance of manufactured components. However, even the most skilled machinists can encounter challenges, such as damaged or poorly formed threads. The FlexArm tapping arm, a versatile tool that can tackle a wide range of threading applications, including chasing threads on 1018 steel round bar.

The Impact of Defective Threads

The end-user, a manufacturing company with high-volume production runs, faced a recurring issue with defective threads on 1018 steel round bar components coming off the lathe. These flawed threads resulted in scrapped parts, leading to financial losses and production delays. In search of a solution, they turned to the FlexArm tapping arm for its ability to effectively chase threads and restore them to their original specifications.

Assessing Threading Performance with the Tap Test

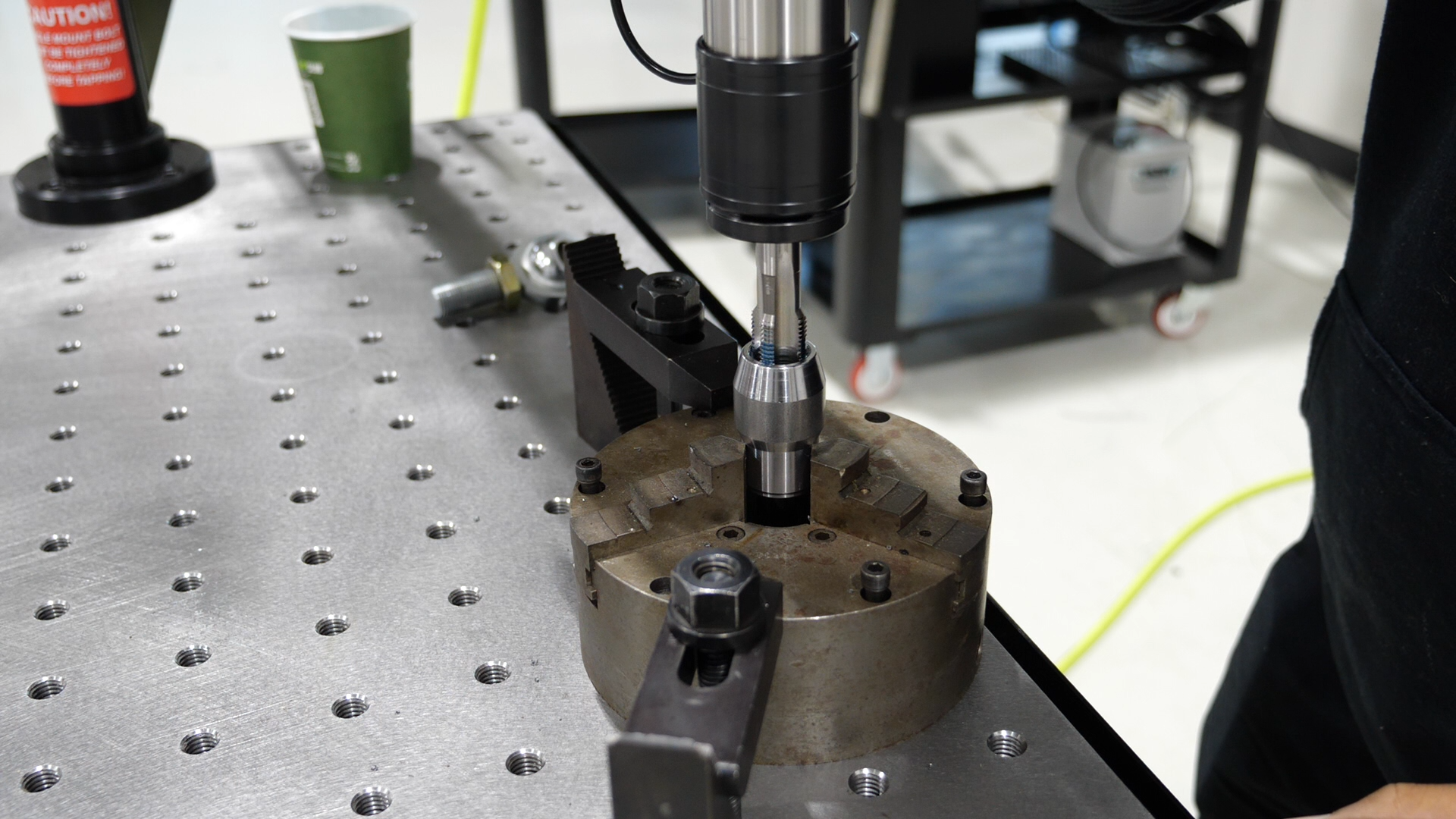

The tap test involved threading a 3/4-16 hole into 1018 steel material round bar. The parts provided by the customer featured left-hand threads, necessitating the use of a 3/4″ fixed holder.

Additionally, the existing threads on the parts were damaged and required chasing to ensure proper functionality.

To conduct the tap test, the FlexArm tapping arm was configured with the appropriate tap and holder. The arm’s versatility allowed for easy adjustments to accommodate the specific dimensions and thread type of the parts. The tapping process was carried out smoothly, with the FlexArm effectively chasing the damaged threads and restoring them to their original form.

Enhanced Production Efficiency and Time Savings

The tap test demonstrated the FlexArm tapping arm’s ability to address threading challenges effectively. By successfully chasing threads on the 1018 steel round bar components, the FlexArm will help the end user reduce scrap parts, improve production efficiency, and minimize financial losses.

Moreover, the FlexArm’s versatility and ease of use make it a valuable asset for any metalworking operation. Its ability to handle a wide range of threading applications, including left-hand threads, makes it a versatile tool that can streamline production processes and reduce downtime.

Conclusion

The FlexArm tapping arm has proven to be a valuable tool for our customer, enabling them to address threading issues and minimize scrap parts. Its versatility, efficiency, and ease of use make it a worthwhile investment for any metalworking operation seeking to enhance its threading capabilities and improve overall production performance. If you are facing a similar problem or unsure if the FlexArm tapping arm can help you with your needs, schedule a tap test today.