Shops all across the country are continuously looking for ways to improve their processes. An Ohio manufacturer specializing in custom roll threaded products was looking to do just that. Seeing that their old drill press was on its last leg, they were on the hunt for a replacement that would work for their Acme tapping process.

When they came upon the FlexArm, they were immediately drawn to its ease of use. However, they were concerned that the FlexArm wouldn’t be able to push their 2″-4 Acme-2G tap. Because of this, they were thinking about purchasing a radial drill instead.

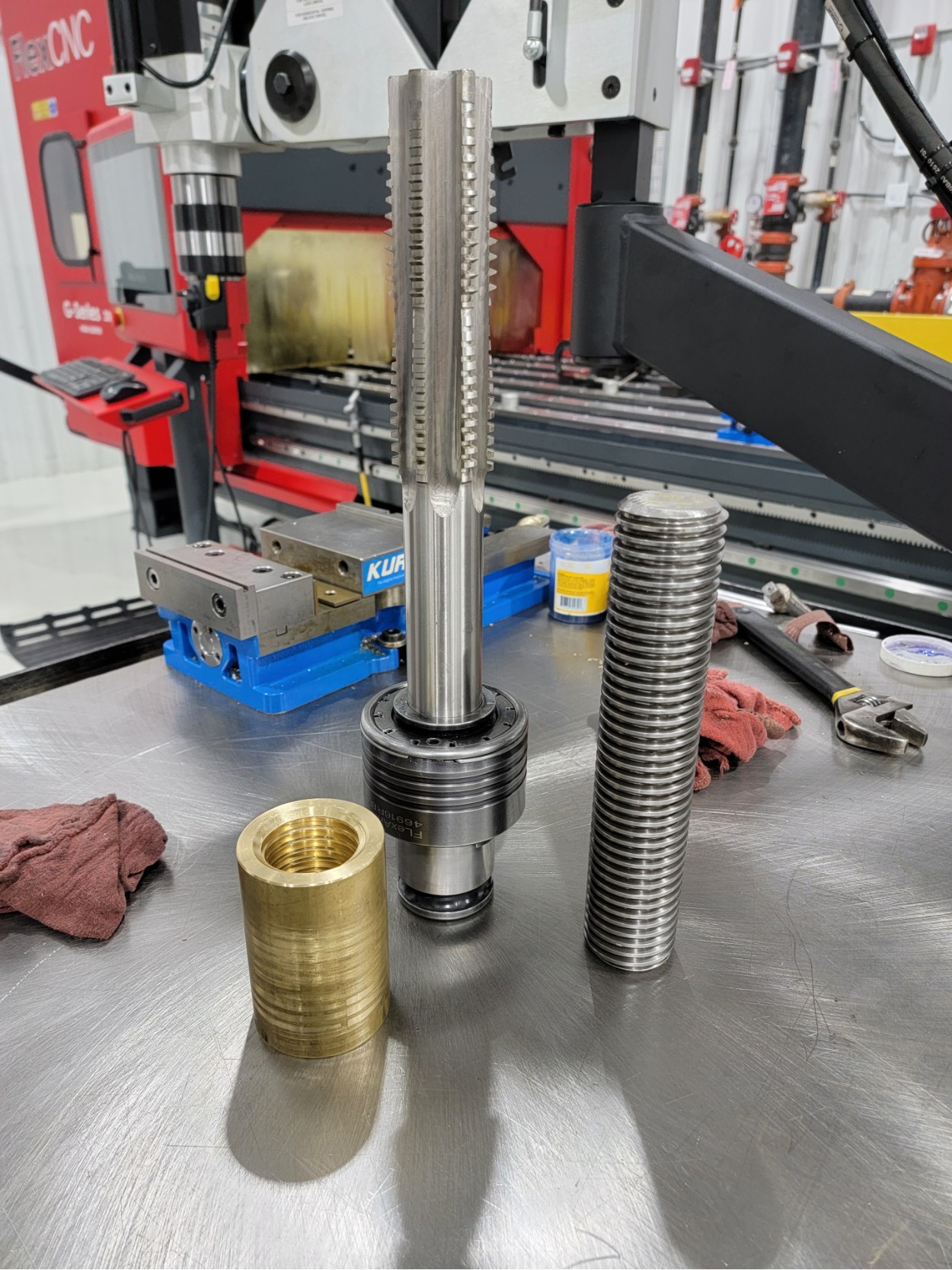

Confident in the FlexArm’s capabilities, the Flex team suggested sending in parts to prove the solution in a tap test. The end-user agreed to send in their bronze parts and have them tested on a hydraulic tapping arm.

The tap test required the GH-60 hydraulic tapping arm due to the substantial amount of torque needed to turn the large Acme tap.

Tap Specs

″-4 Acme 2G

Major Diameter – 2.02/2.04

Minor Diameter – 1.7500/1.7625

Threads Per Inch – 4

Length of Thread – 2.75

After setting up the fixturing, we tapped the bronze nut running the tap between 30 RPM-50 RPM. The GH-60 tapping arm tops out at 811 ft/lbs of torque, which was just the right amount to create perfect Acme threads with ease.

If you have a similar application or looking for a quick and easy tapping solution, give us a call at 1-800-837-2503 or schedule a tap test today.