Installing threaded inserts by hand can be time consuming and inaccurate. One of our customers faced this problem when it came to installing inserts into their pre-molded plastic chair bases. The FlexArm engineering team came up with a solution.

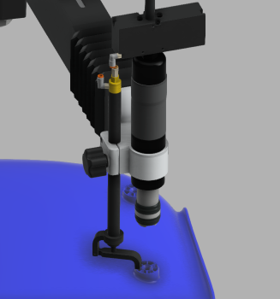

To speed up the process of installing inserts, our engineers selected the A-32 pneumatic tapping arm. For this process, an operator machinist aligns the arm and insert with the hole, pushes the forward lever, and while applying slight downward pressure, allows the pneumatic motor to do all of the work screwing in the insert. The machinist can then quickly guide the arm to the next hole. By utilizing the A-32 tapping arm, the time it takes to install each insert is drastically reduced compared to installing them by hand.

While the pneumatic tapping arm solved the problem of speed, the issue of inaccuracy still remained. Each insert was not being installed to the same depth in the plastic. Typically FlexArm’s standard automatic depth stop is

the simple solution to this problem. However, for this application, the threaded inserts are installed into a standoff on the chair base. The standoff is too narrow for the standard depth stop to reach.

The FlexArm engineering team designed a modified version of the pneumatic automatic depth stop. A custom assembly with a “finger” is used on the end of the depth stop to allow it to touch the ring of the standoff in which the inserts are being installed. When this “finger” touches a part’s standoff ring, the air supply to the motor is cut off, stopping the motor, and installing the insert to the predetermined depth.

By using this customized automatic depth stop with the A-32 tapping arm, the customer is able to install threaded inserts to an exact depth quickly and accurately every time.

If you are interested in a custom ergonomic solution, contact us or give us a call at 1-800-837-2503.