Watch the video of this application at the bottom of this page.

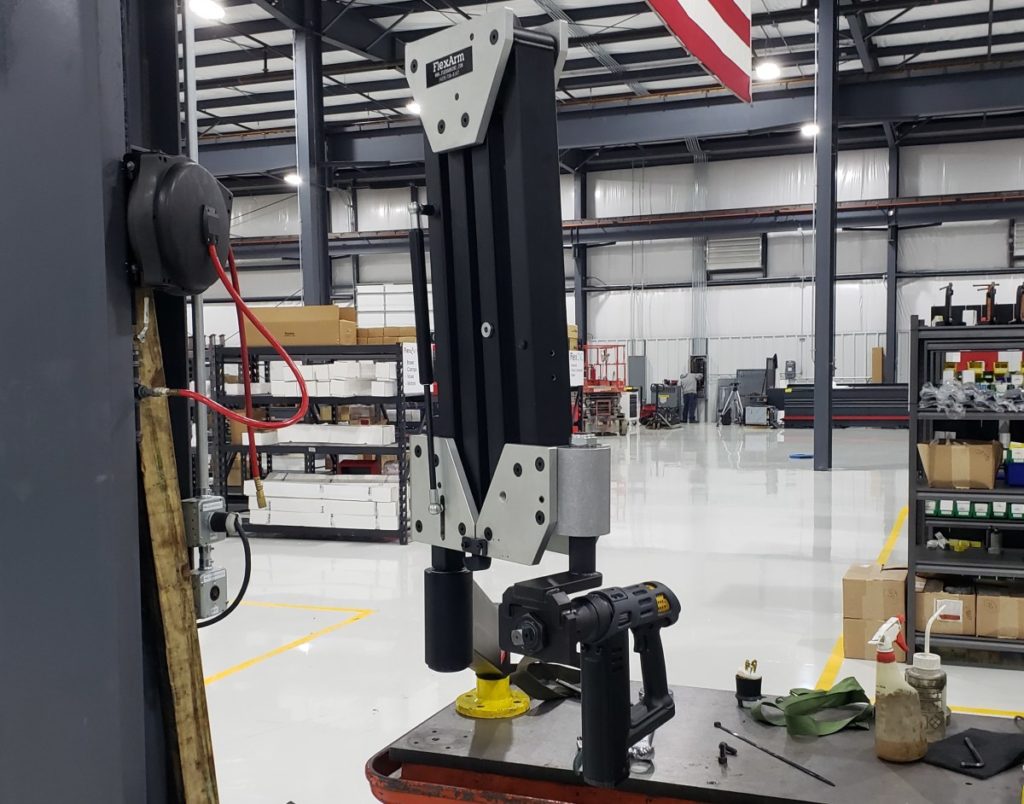

We had a customer looking for a torque reaction solution that could counterbalance a 25-pound pistol grip nutrunner, so we took the manufacturer’s reaction plate (Atlas Copco) and welded it to the front of the custom mount on the G-30 FlexArm.

The mount allows the operator to rotate the tool inside of its housing inside of the reaction plate, and align it any way they need. Once the tool is engaged, the reaction plate itself will eat up the 500 Newton Metres of torque.

The G-30 FlexArm has a reach up to 73 inches, allowing the operator to easily maneuver the tool and reach their desired area.

Contact us today or give us a call at 1-800-837-2503, if you’re interested.