Throughput is the number one metric for assessing the quality of a production line, and increasing throughput on a CNC means increased profitability. Flex Machine Tools is always looking for ways to help manufacturers and fabricators speed up production and increase throughput. The FlexCNC Vertical Machining Center, paired with Allied Machine & Engineering tooling, increases productivity and lowers the cost per part by decreasing tool changes, improving cycle times, and eliminating spindle downtime.

The FlexCNC is more efficient and has a higher throughput rate than other machines because it allows for 100% spindle uptime, which means the spindle never stops. The pendulum mode allows an operator to add and remove parts while the machine continues to run at the other end of

the bed. An operator can load the bed with as many parts as they want, and never have to stop the machine. This results in a higher throughput rate than machines that must stop every time the door opens.

An easy way to increase throughput even further is by speeding up the cycle time. This can be accomplished by eliminating tool changes and second passes with a combination tool. We tested the Allied Machine & Engineering combo drill/chamfer tool on the FlexCNC because we wanted to see how much we could increase the throughput rate by speeding up the cycle time.

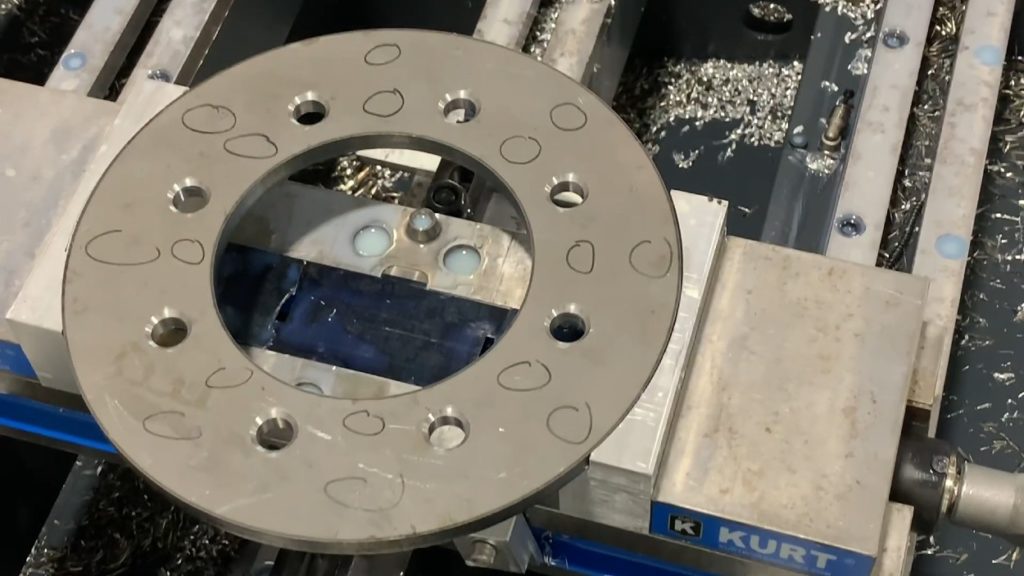

ALLIED DRILL/CHAMFER COMBO DRILL TEST

Allied Drill Tool Body – 60117C45-075F

We ran the part at 350sfm (1992 rpm) feeding it at .012”ipr (24ipm)

Drill insert diameter – 43/64” (.6719)

Chamfer diameter – 1.00”

RESULTS

The cycle time for this part was 1 minute 47 seconds, which comes out to 3.5 seconds per hole. Using a drill and a separate chamfering tool would have added a significant amount of time to the machining process. The added tool change time and travel time would have made the cycle time approximately 4 minutes 30 seconds. However, using a combo tool resulted in a time savings of almost 300%.

Save time and money by increasing your throughput with FlexCNC and Allied Machine & Engineering tooling. Eliminate spindle downtime with Pendulum Mode, improve cycle times and eliminate tool changes with Allied combination tools. If you are interested in increasing your throughput by 300% or more give us a call at 1-800-837-2503 or contact us today.