- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here

Flex Machine Tools Partners with IGEMS to Elevate Waterjet Cutting Technology in North America

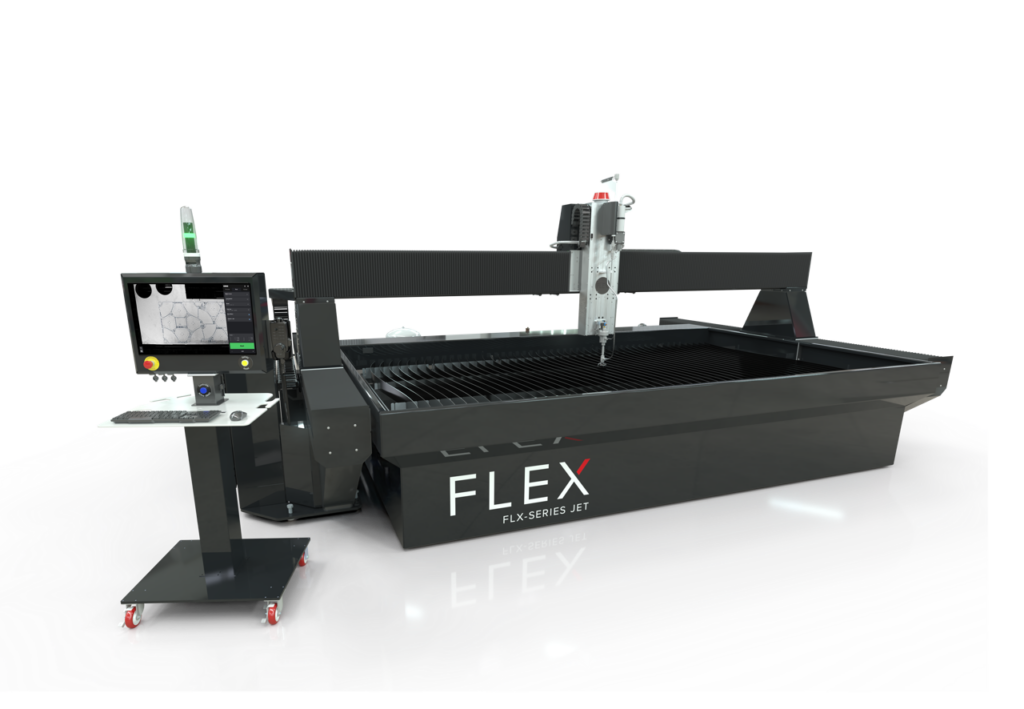

FlexJet powered by IGEMS CNC and CAD/CAM software is a collaboration between Ohio-based Flex Machine Tools and IGEMS of Sweden.

The FlexJet will be integrated with the IGEMS CNC and its 5-axis waterjet cutting head known as the “Tilter”.

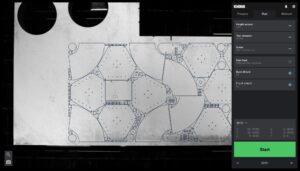

Known for its precision and versatility, the FlexJet will now boast enhanced capabilities thanks to IGEMS’ software, including the advanced Tilter, Snapper (the camera for optimal positioning), Rounder (the kinematic compensation tool), and Straighter (the perpendicular angle tool) functionalities. These improvements are designed to cater to the intricate needs of diverse materials and cutting requirements, ensuring unparalleled accuracy and efficiency in waterjet cutting processes. Adding to the technological advancements, the FlexJet will be equipped with Beckhoff’s state-of-the-art industrial PC, and IGEMS’ HMI. This integration signifies a significant leap in operational control and user experience, offering intuitive interfaces and robust performance that redefine industry standards.

Known for its precision and versatility, the FlexJet will now boast enhanced capabilities thanks to IGEMS’ software, including the advanced Tilter, Snapper (the camera for optimal positioning), Rounder (the kinematic compensation tool), and Straighter (the perpendicular angle tool) functionalities. These improvements are designed to cater to the intricate needs of diverse materials and cutting requirements, ensuring unparalleled accuracy and efficiency in waterjet cutting processes. Adding to the technological advancements, the FlexJet will be equipped with Beckhoff’s state-of-the-art industrial PC, and IGEMS’ HMI. This integration signifies a significant leap in operational control and user experience, offering intuitive interfaces and robust performance that redefine industry standards.

“This partnership with IGEMS represents a pivotal step forward in our commitment to providing innovative and high-quality solutions to the North American market,” said Don Kemper, President of Flex Machine Tools. “By combining IGEMS’ exceptional software with Beckhoff’s leading-edge hardware on our FlexJet machines, we are setting a new benchmark for precision, efficiency, and reliability in waterjet cutting technology.” The collaboration between Flex Machine Tools and IGEMS is a testament to both companies’ dedication to technological advancement and customer satisfaction.

Josefin Larsson, CEO of IGEMS stated “IGEMS has over 40 years of experience developing CAD/CAM software for the waterjet cutting industry worldwide. To be able to perform the best cutting result we started six years ago to develop our own CNC controller, and with installations already done in Europe, we are proud to now launch our CNC to the US market together with our partner Flex Machine Tools. With Flex Machine Tools’ skill in producing cutting machines and IGEMS’s knowledge around software, we will together bring the most capable solution to market, saving time and creating profitable partnerships for end-users. We are especially proud that Flex Machine Tools has chosen a full solution from IGEMS – Our CAD/CAM together with our CNC controller, cutting head and calibration hardware. We call it ‘Yellow Magic!’”

Josefin Larsson, CEO of IGEMS stated “IGEMS has over 40 years of experience developing CAD/CAM software for the waterjet cutting industry worldwide. To be able to perform the best cutting result we started six years ago to develop our own CNC controller, and with installations already done in Europe, we are proud to now launch our CNC to the US market together with our partner Flex Machine Tools. With Flex Machine Tools’ skill in producing cutting machines and IGEMS’s knowledge around software, we will together bring the most capable solution to market, saving time and creating profitable partnerships for end-users. We are especially proud that Flex Machine Tools has chosen a full solution from IGEMS – Our CAD/CAM together with our CNC controller, cutting head and calibration hardware. We call it ‘Yellow Magic!’”

With this partnership, customers in North America can expect to experience enhanced cutting performance and increased productivity, thereby transforming their operational capabilities, with the first machines being deliverable by April 8, 2024.

Flex Machine Tools is a leading provider of cutting-edge manufacturing and fabrication solutions. With a focus on innovation and quality, Flex Machine Tools offers a wide range of products and services designed to meet the evolving needs of the industry. For more information, please visit www.flexmachinetools.com or contact info@flexmachinetools.com.

IGEMS is at the forefront of CAD/CAM software development, specializing in solutions that optimize cutting processes for improved precision and efficiency. With a commitment to innovation and customer support, IGEMS continues to shape the future of the manufacturing sector.

Related Topics

Five Dynamic Uses for the FlexCNC

The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC can perform various functions for numerous specialized projects, saving you space and money with...

Read MoreFlex Machine Tools Launches the new Flexible Tapping Center

Flex Machine Tools is excited to launch a new product that will revolutionize your workshop: the Flexible Tapping Center (FTC). This specialized machine is equipped with superior precision, innovation, and performance to produce quality products for your business. Typically,...

Read More

Take the Risk Out of Choosing Tapping Arms:

Free Tap Test by FlexArm

When selecting machinery for your company, deciding what tools will work best for your product can be overwhelming, and it can feel like a risk when you need to know if the product you bought will be the right...

Read More