Let us automate your CNC programming

Program My Part

FlexCare+ is an on-demand programming service available for all FlexCNC customers

When it comes to programming a FlexCNC, no one does it better than us. Whether you already own a FlexCNC or are in the market for one, we can help you maximize your productivity.

Cut Cycle Times in Half or More!

·

Improve Spindle Uptime – 100%

·

Eliminate Bottlenecks in Programming

How Does It Work

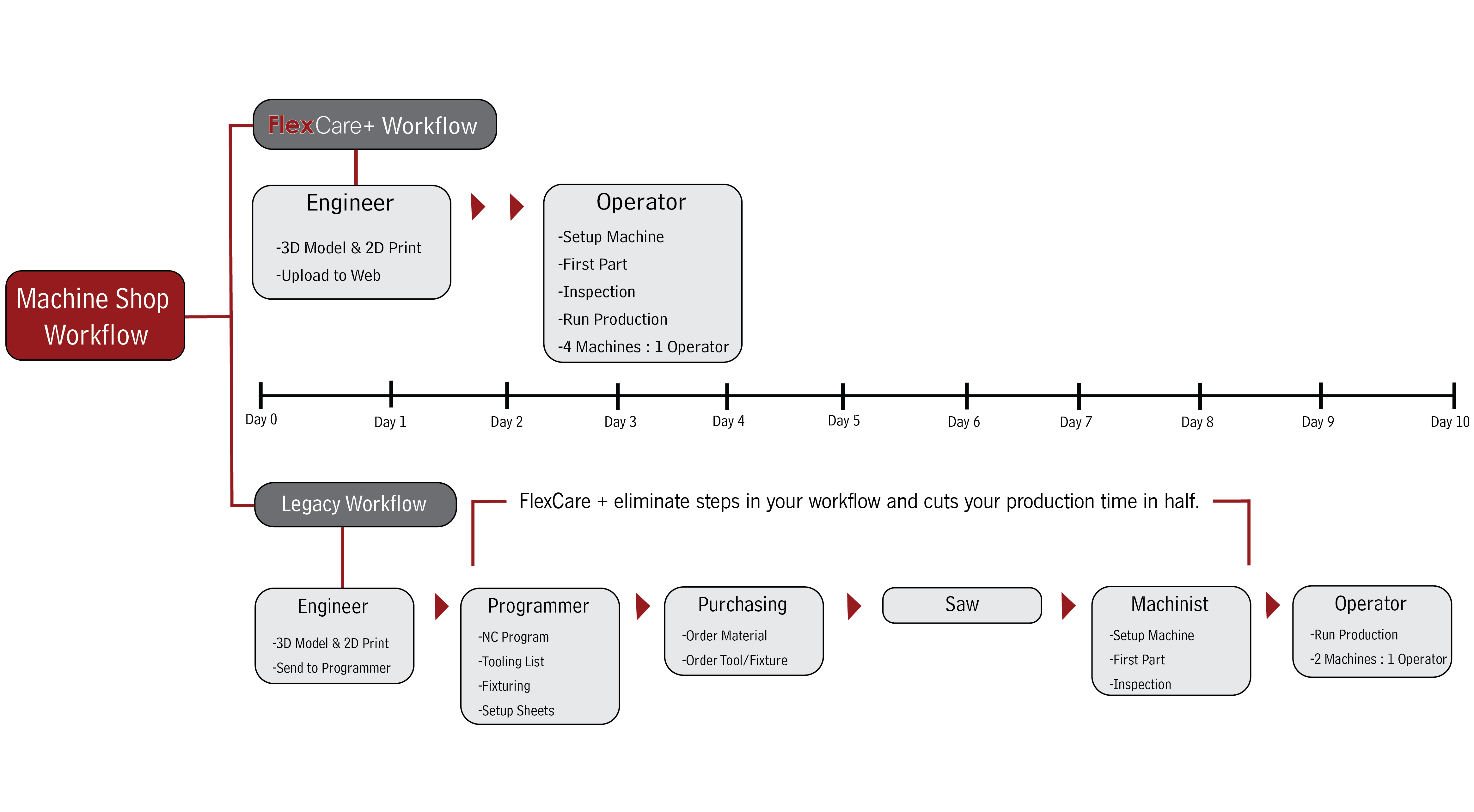

Workflow

Benefits

Quote Examples

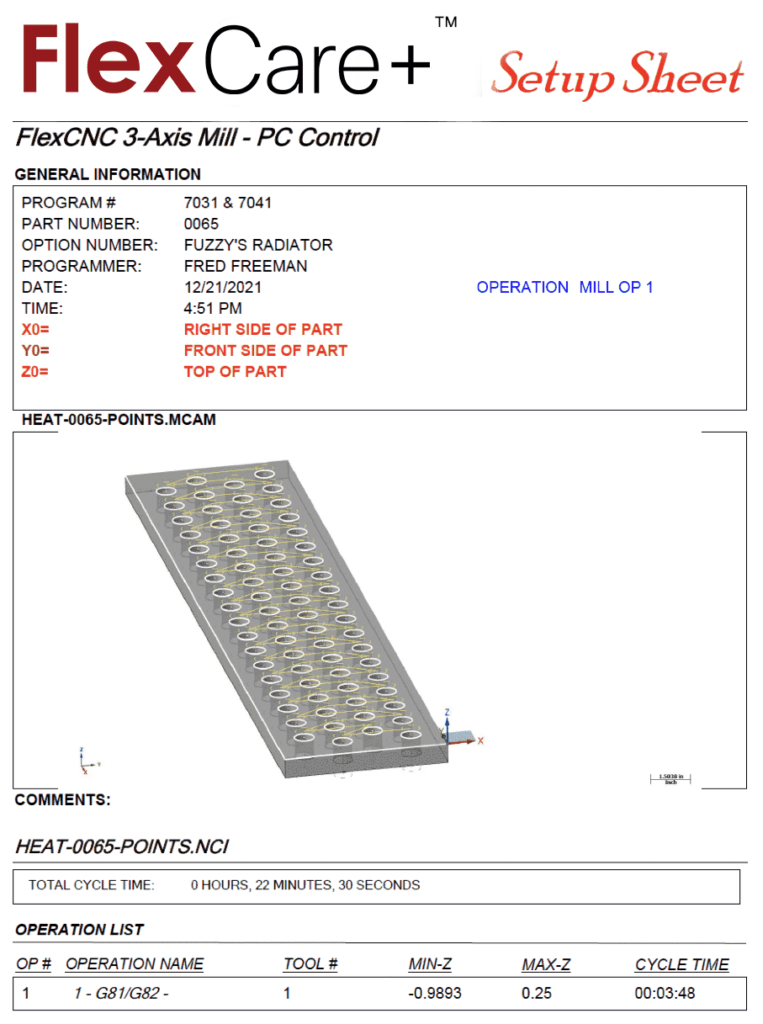

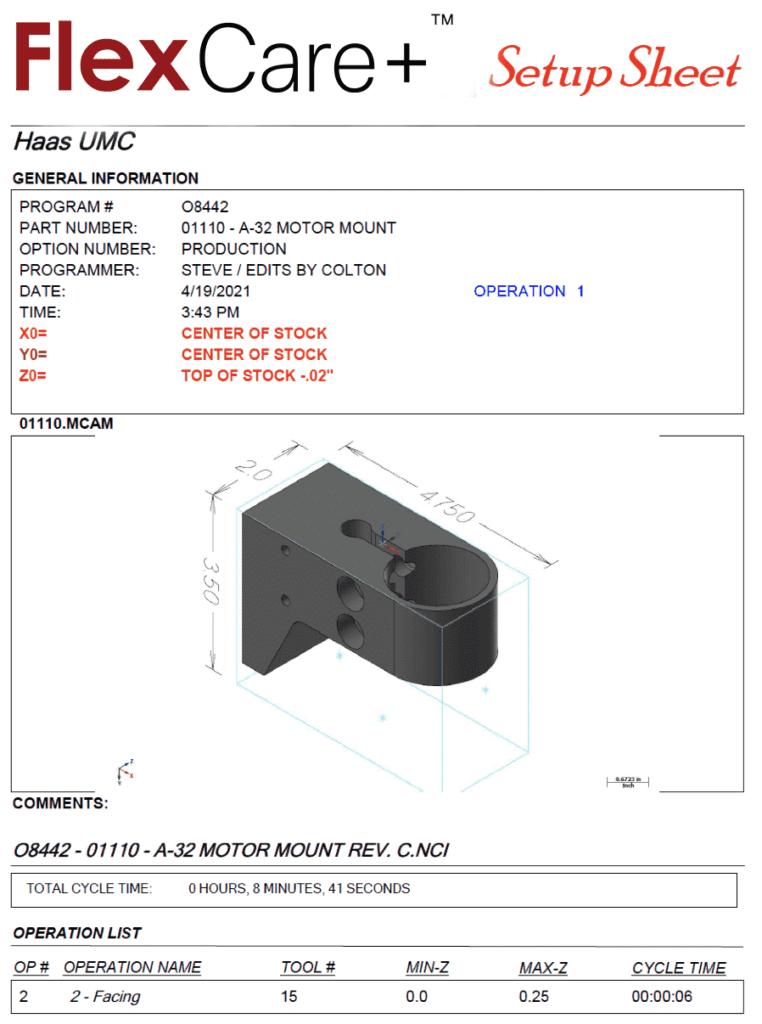

Set Up Sheet Example

How Does It Work

Let us Automate your CNC Programming

1) Upload your 3D model and receive an instant quote

2) Select option for purchase

3) Receive the NC Program, Setup Sheets, and Tooling List

G21

G0 G17 G40 G49 G80 G90

( 16 RG)

M8

T15 M6

G0 G90 G55 X-46.124 Y-60.164

G43 H15 Z50

Z – 9 . 9

G1 X-48.797 Y-59.151 F400.

X-51.395 Y-58.165

G3 X-51.75 Y-58.1 R1 .

G1 X-64.967 Y-57.006

G2 X-66.207 Y-56.802 R10.031

X-69.346 Y-55.657 R13.76

X-72.621 Y-53.59 R21.206

X-76.447 Y-50.235 R40.468

X-79.2 Y-47.404 R95.055

G1 X-82.856 Y-43.428

G2 X-85.012 Y-40.391 R12.631

X-86.329 Y-36.925 R17.826

X-87.198 Y-31.81 R30.123

X-87.399 Y-25.32 R64.412

G1 X-87.324 Y-22.153

G2 X-86.713 Y-18.871 R12.012

G0 G17 G40 G49 G80 G90

( 16 RG)

M8

T15 M6

G0 G90 G55 X-46.124 Y-60.164

G43 H15 Z50

Z – 9 . 9

G1 X-48.797 Y-59.151 F400.

X-51.395 Y-58.165

G3 X-51.75 Y-58.1 R1 .

G1 X-64.967 Y-57.006

G2 X-66.207 Y-56.802 R10.031

X-69.346 Y-55.657 R13.76

X-72.621 Y-53.59 R21.206

X-76.447 Y-50.235 R40.468

X-79.2 Y-47.404 R95.055

G1 X-82.856 Y-43.428

G2 X-85.012 Y-40.391 R12.631

X-86.329 Y-36.925 R17.826

X-87.198 Y-31.81 R30.123

X-87.399 Y-25.32 R64.412

G1 X-87.324 Y-22.153

G2 X-86.713 Y-18.871 R12.012

Run Time 5 min

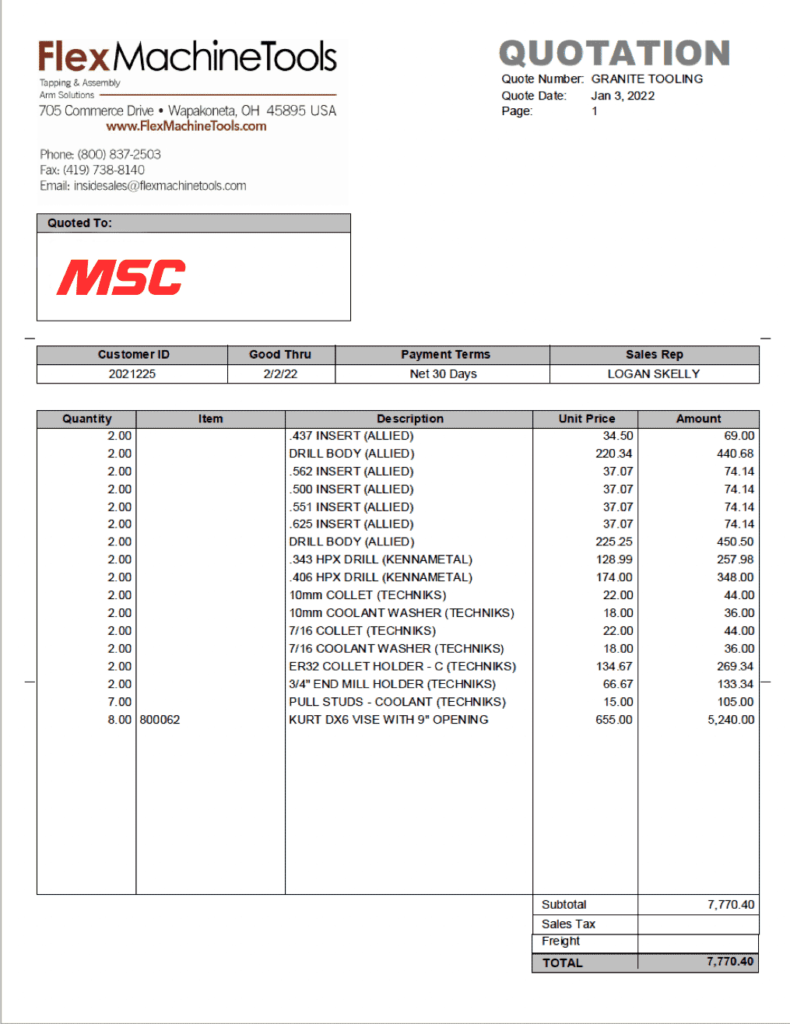

4) Additional quote for tooling to support the NC Program

Workflow

Benefits

FlexCare+ Would Benefit You When:

✓ You want to optimize your programs

✓ You’re struggling to recruit experienced programmers

✓ For streamline manufacturing

✓ Trouble-free programming

✓ It’s taking way too long to program parts

✓ You’re too busy to write all programs

✓ You need on-demand support

✓ You need tooling and fixturing recommendations

✓ Faster Cycle Times

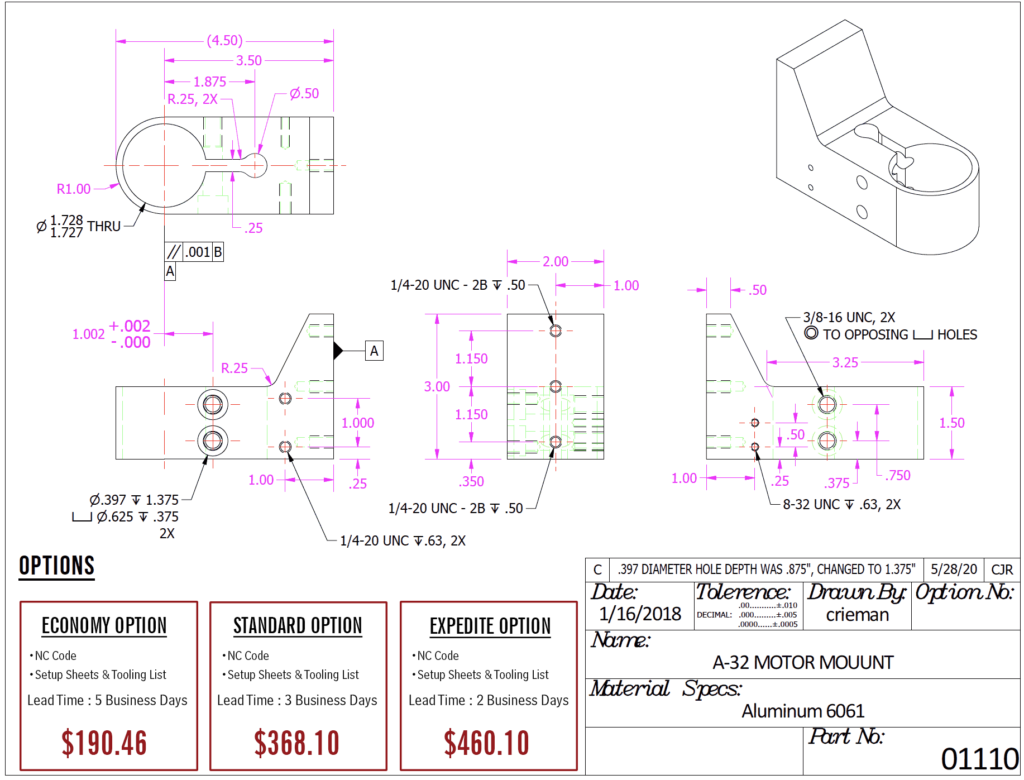

Quote Examples

Set Up Sheet Example

Testimonial

“I’ve leaned on FlexCare+ to help me with programming parts along with being able to call them and get help with questions I may have about tools or programs...It has honestly been a blessing. I’d highly recommend it for anyone that might have a new machinist. The response time it’s great and the turnover on getting programs back is more than satisfactory.”

- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here