Tube Laser

Is a Tube Laser Overkill for Your Shop? Imagine a machine that’s more affordable, versatile, and capable of handling larger diameters and thicker materials. Meet

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Is a Tube Laser Overkill for Your Shop? Imagine a machine that’s more affordable, versatile, and capable of handling larger diameters and thicker materials. Meet

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make

“FlexJet has really helped me stand out among my competitors.” Some of my projects take days, but The FlexJet runs in the background. It’s freed

“FlexJet has really helped me stand out among my competitors.” Some of my projects take days, but The FlexJet runs in the background. It’s freed

“FlexJet has really helped me stand out among my competitors.” Some of my projects take days, but The FlexJet runs in the background. It’s freed

REQUEST SERVICE To get started, fill out the form below or call us at 937-210-9031. What Do You Need Help With?*Select OneFlexArm ServiceFlexCNC ServiceFlexJet ServiceMotion

All FlexJet models come with a multitude of customizations, including the type of cutting head. The waterjet cutting head you choose can depend on many

Maintaining tight tolerances is critical for delivering quality parts, reducing scrap, and avoiding costly rework. Even the best machining centers can struggle to hold tolerances

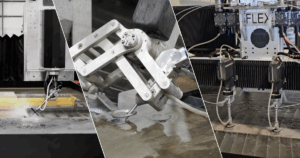

Waterjet cutting is one of the most versatile and precise material processing technologies available today. Whether you’re cutting metal, plastic, glass, or composite materials, waterjet

As published in The Fabricator on March 25, 2025. View article here. Perhaps you are investigating a significant machine tool investment and weighing the options

March, 2025- With a business model based on the aspiration to do everything from project concept to implementation, Fulcrum Technologies Inc. wanted to become more

Click to Zoom In Applicant Information Would you prefer to upload your resume or fill out an application?(Required)Upload a ResumeFill out an Application Name(Required) First

In the world of CNC machining, choosing the right tooling and setup for your application can significantly impact efficiency, precision, and cost. Two powerful options

Click to Zoom In Applicant Information Would you prefer to upload your resume or fill out an application?(Required)Upload a ResumeFill out an Application Name(Required) First

In manufacturing, productivity and efficiency are core concepts often misconstrued or used synonymously despite their importance to improving company throughput. Knowing the differences and intricacies

JOIN US at the OPEN HOUSE Discover the latest advancements with FLEX products. Don’t miss the opportunity to see our equipment in action and learn

Fabtech Dealer Training Name(Required) First Last Email(Required) Phone(Required)

Click to Zoom In Applicant Information Would you prefer to upload your resume or fill out an application?(Required)Upload a ResumeFill out an Application Name(Required) First

Join Us at IMTS 2024 MCCORMICK PLACE | SEPTEMBER 9-14, 2024 | CHICAGO, IL | BOOTH #135204 Experience the evolution of a manufacturing icon at

Download Flexjet INFORMATIONAL GUIDE Name* First Last Company* Work Email Address* Phone* ZIP Code* CAPTCHA

Click to Zoom In Applicant Information Would you prefer to upload your resume or fill out an application?(Required)Upload a ResumeFill out an Application Name(Required) First

Click to Zoom In Applicant Information Would you prefer to upload your resume or fill out an application?(Required)Upload a ResumeFill out an Application Name(Required) First

WATERJET SOLUTION The precise FlexJet Waterjet is equipped with an IGEMS CNC control, CAD/ CAM software and hardware including the advanced Tilter 5-Axis waterjet cutting

Waterjet cutting is a manufacturing process that uses highly pressurized water, sometimes with an abrasive, for an accelerated eroding process that can cut and shape

FLEX WATERJET SERVICES Where every cut is a step forward, and every moment counts. ABOUT FLEX SERVICES With Flex, we don’t just provide you with

FMT | Flexarm Manuals FLEXCNC • C-Series Operating Manual • C-Series Installation and Maintenance Manual • G-Series Operation Handbook • G-Series Installation and Maintenance Manual

Privacy Policy Effective date: October 24, 2019 Midwest Specialties, Inc. (“us”, “we”, or “our”) operates the https://flexmachinetools.com/ website (hereinafter referred to as the “Service”). This

| FLEX SERVICE At Flex Machine Tools, our highly educated service technicians are dedicated to keeping your business running smoothly. They provide expert support for

REQUEST A QUOTE HELLO! HOW CAN WE HELP YOU? Tapping Arms, Torque Reaction Arms, Balancing Arms, Helicoil Arms, Part Manipulators, Die Grinders, & Accessories Request

Is repetitive lifting causing backaches, fatigue, and injuries in your manufacturing facility? This can lead to a revolving door of employees, costing you time, money,