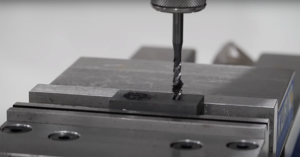

Tapping 7/16” Holes into 3/8” Thick Steel

An end-user out of North Carolina was looking for a more efficient way to tap their parts. They wanted to see how the FlexArm could

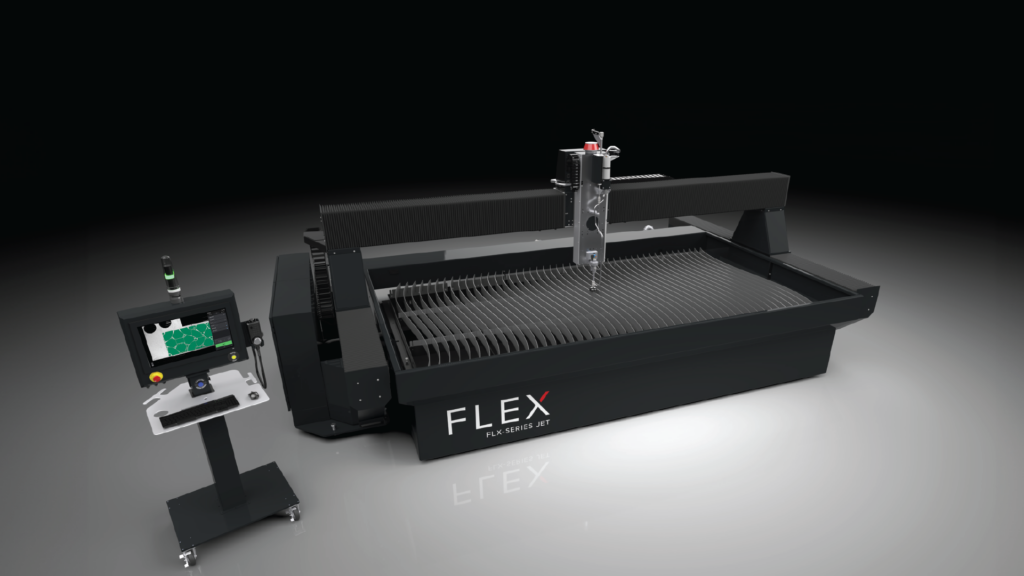

Waterjet Speed like you have never seen before. IGEMS has partnered with FlexJet to create the most innovative machine on the market. With only a few key features, Flexjet far surpasses the competition in speed, precision, and efficiency.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

An end-user out of North Carolina was looking for a more efficient way to tap their parts. They wanted to see how the FlexArm could

Watch the video of this application at the bottom of the page. A customer from Trotwood, Ohio, needed to tap precise and consistent NPT threads

One of our distribution partners had an end-user that was interested in trying a FlexArm. The end-user, Magnum Precision Machines, is a job shop that

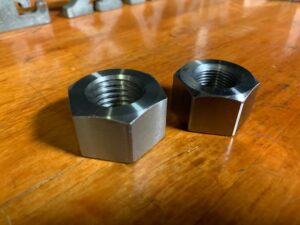

We had a customer send in some nuts for us to tap, so we put the GH-60 Hydraulic FlexArm tapping solution to the test.

Watch the video of this application at the bottom of the page. An end-user reached out to us looking for a better tapping solution to

Watch the video of this application at the bottom of the page. Here is an example of a very simple torque reaction solution. A customer

“We use the FlexCNC for two very specific uses, one of which we had an old machine for and another that we use to do by hand.

A prospect reached out to us because they were interested in trying out one of our tapping arms. PowerBuilt Material Handling Solutions, out of Bellefontaine,

In the world of metalworking, precision and efficiency are paramount. Threading holes accurately and consistently is essential for ensuring the integrity and performance of manufactured

“As a manufacturer of architectural railing systems and components, R&B Wagner, Inc. is always looking for the best way to fixture and machine long lengths

When faced with production tapping, having the right tool for the job can save both time and money. Here is one situation where the FlexArm

CNC machinery can have problems arise, and some of these problems are more common than others. When these problems occur, FlexCare+ steps in to get them resolved

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

Petty Welding is a fabrication shop in Knoxville, Tennessee, that focuses on welding, fabrication, custom-iron work, and on-site repair. They’ve been in business for 11 years,

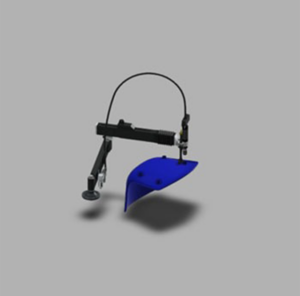

Watch the video of this application at the bottom of this page. A customer contacted us interested in an arm that could counterbalance a

Flex Machine Tools is excited to introduce a new offering to its line of ergonomic balance arms: the FlexArm B-33. The B-33 Zero-Gravity Balance Arm is a larger

Today, US manufacturing is widely misunderstood, especially among young people. Manufacturing remains central in the world economy yet is seen as an outdated and dying

Handheld grinders are essential tools in metalworking environments, but using them can be taxing and tiring for the user. With companies striving to minimize lost

Richard Kennedy launched Midwest Specialties, Inc., in 1971 as a government contracting manufacturing business. He designed and built a tapping arm to increase speed and

In industries that rely heavily on drilling, the efficiency and precision of the equipment used can significantly impact productivity. FlexArm is proud to introduce the FlexArm

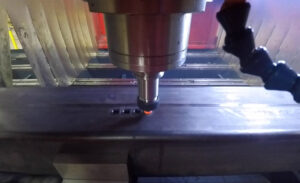

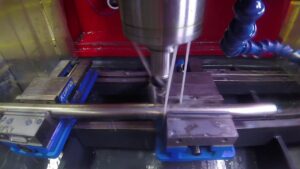

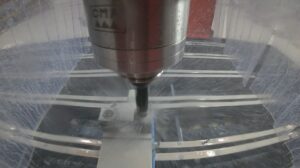

Eliminating Spindle Downtime Imagine being able to machine a bunch of different parts in one machining center without ever stopping the spindle. I know what

A customer came to Flex looking for an ergonomic solution to help lift and maneuver a 40-pound Milwaukee Tool Electromagnetic drill press. The weight is often

MACHINING CENTERS FOR FABRICATORS CNC Machining Centers are the shop workhorse that can handle some of the most challenging parts faster. Fab shops with CNC

John Saunders, a.k.a. “NYC CNC,” is the guest for this week’s episode of Fireside Chats. During this interview, we discuss a variety of different topics,

WATCH FULL CUSTOMER STORY BELOW In the fabrication industry, staying ahead of your competitors is always crucial. With continued technological advancements, businesses need a well-rounded

Installing threaded inserts by hand can be time consuming and inaccurate. One of our customers faced this problem when it came to installing inserts into

The Problem with Heavy Tools Bolting applications often require heavy tools such as torque wrenches and impact wrenches to achieve the appropriate level of tightness

Watch the video of this time study at the bottom of the page Using a CNC Machining Center to drill is safer, faster, and more

Tapping small holes can be a challenge. You are guaranteed to break taps whether you tap by hand, with a cordless drill, or in a

HOW TO TAP GRAPHITE? Tapping graphite, a notoriously soft and brittle material, presents a significant challenge. Finding reliable information on how to tap graphite is