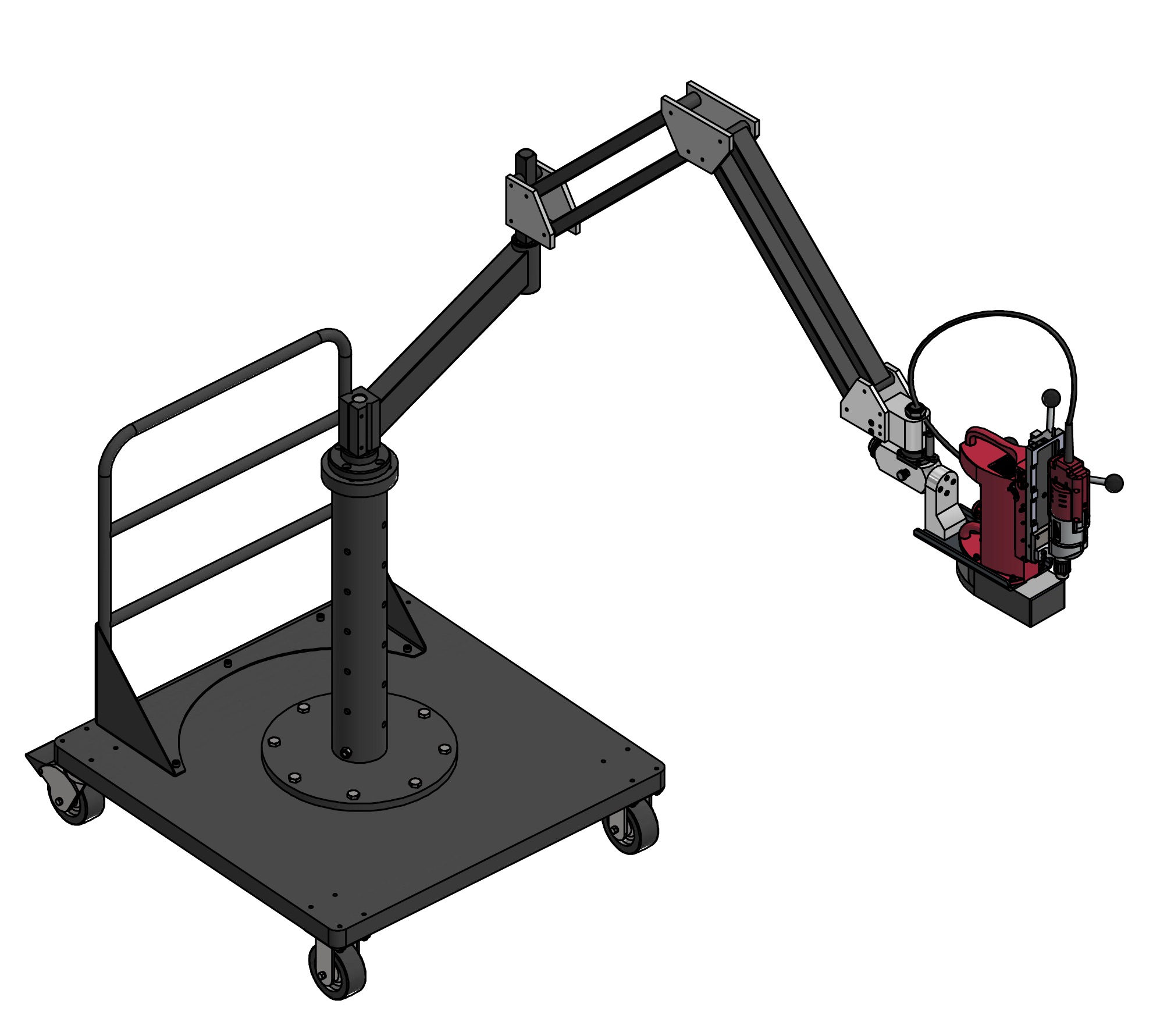

In industries that rely heavily on drilling, the efficiency and precision of the equipment used can significantly impact productivity. FlexArm is proud to introduce the FlexArm Mag Drill Arm, a cutting-edge innovation that simplifies drilling with a mag drill while reducing operator fatigue.

A notable feature of this ergonomic solution is its capacity to offset the tool’s weight by effectively reducing up to 75 pounds of strain on the operator’s body. The arm also provides a working range of up to 100 inches of horizontal reach and 52 inches of vertical stroke, providing precision and versatility across a broad spectrum of drilling tasks. Whether you’re working on vertical surfaces or horizontal applications, this arm offers the flexibility needed without added complexity.

Versatility is key in any tool, and the Mag Drill Arm delivers on this front. With 220° vertical rotation and ±90° horizontal rotation, complete with locking detents, the tool remains securely in place and readily accessible at all times. The Mag Drill arm is also designed to integrate seamlessly with most magnetic drill makes and models via a specially designed mount plate for your specific model. This compatibility reduces the need for costly equipment replacements and ensures a smooth transition.

The inclusion of a mobile base further enhances the convenience of using the Mag Drill Balance Arm. Whether you need to move it between workstations or position it on large workpieces, this feature optimizes your drilling operations, allowing you to work more efficiently.

In industries where the weight of magnetic drills can be a significant challenge, causing discomfort and physical strain during extended use, the FlexArm Mag Drill Arm offers a practical solution. It reduces operator fatigue and prioritizes safety by maintaining a secure and balanced setup.

To request a quote or schedule a demonstration, please fill out the form HERE.