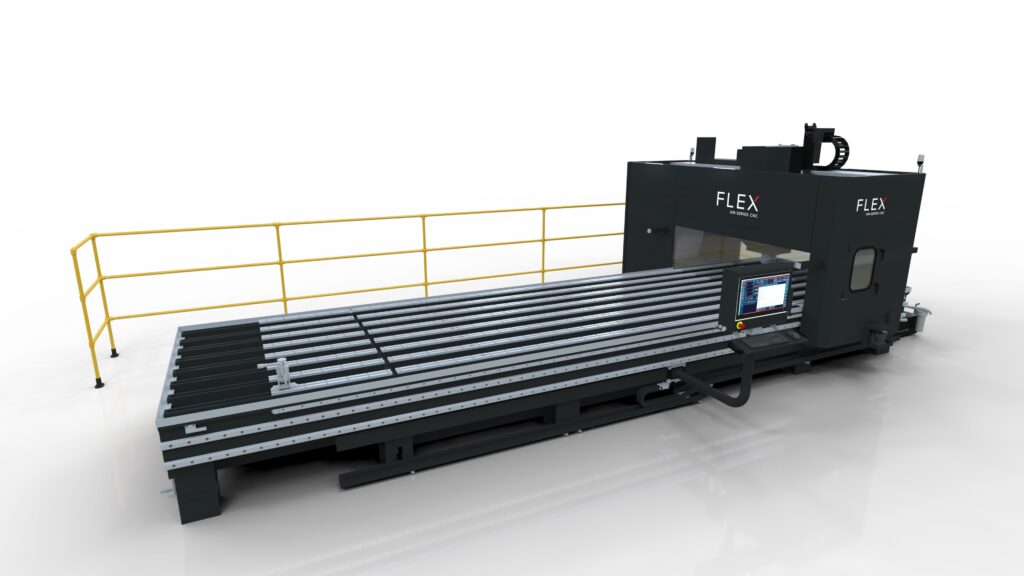

G-Series

Vertical Machining Center

Model: G-20-06

Model: G-10-06

Specifications

Repeatability Accuracy [in]

Position Accuracy [in]

Model: GM-20-06

Specifications

Repeatability Accuracy [in]

Position Accuracy [in]

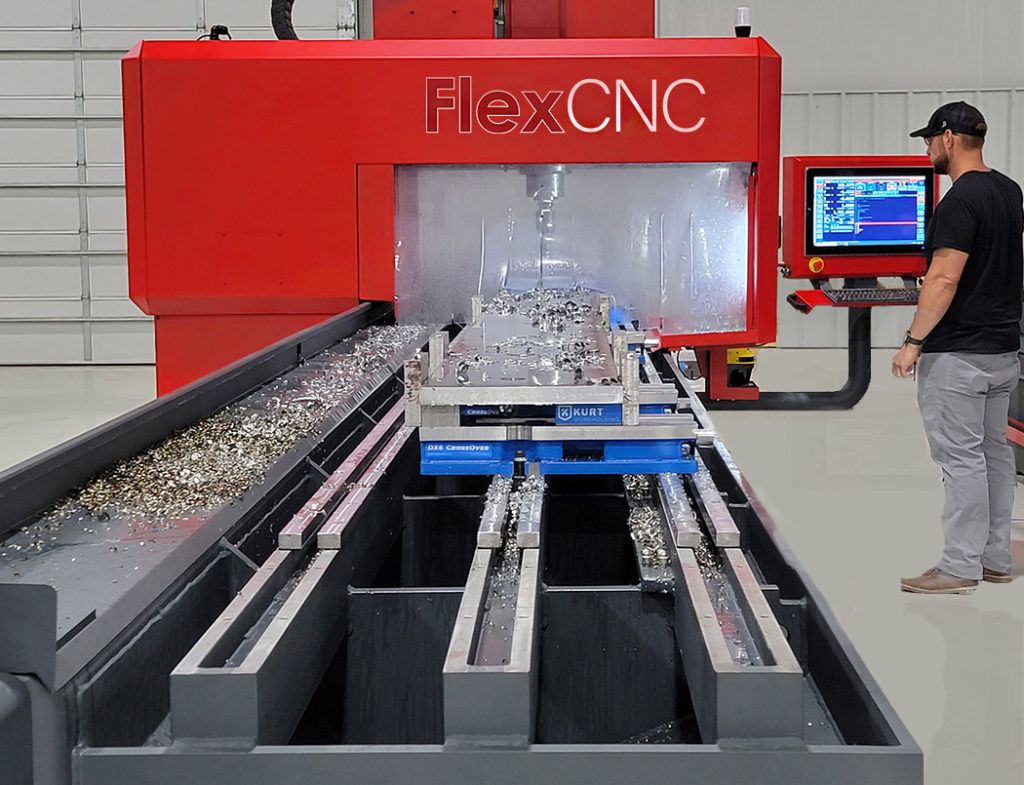

Purpose built

From the monoblock welded steel frame to the precision linear guideways, each FlexCNC is specially built to move accurately and effectively. Stability and durability you need when you need it the most.

Uniquely capable

Mill, Drill, Tap, and so much more with one of the industry’s most versatile vertical machining centers. Say goodbye to limited machine space. and start machining outside the box.

Next level productivity

Automate your operations with FlexCNC’s Pendulum Mode. Load and unload your parts on one side of the bed while the tool turns on the other, keeping your operations safe and the spindle moving.

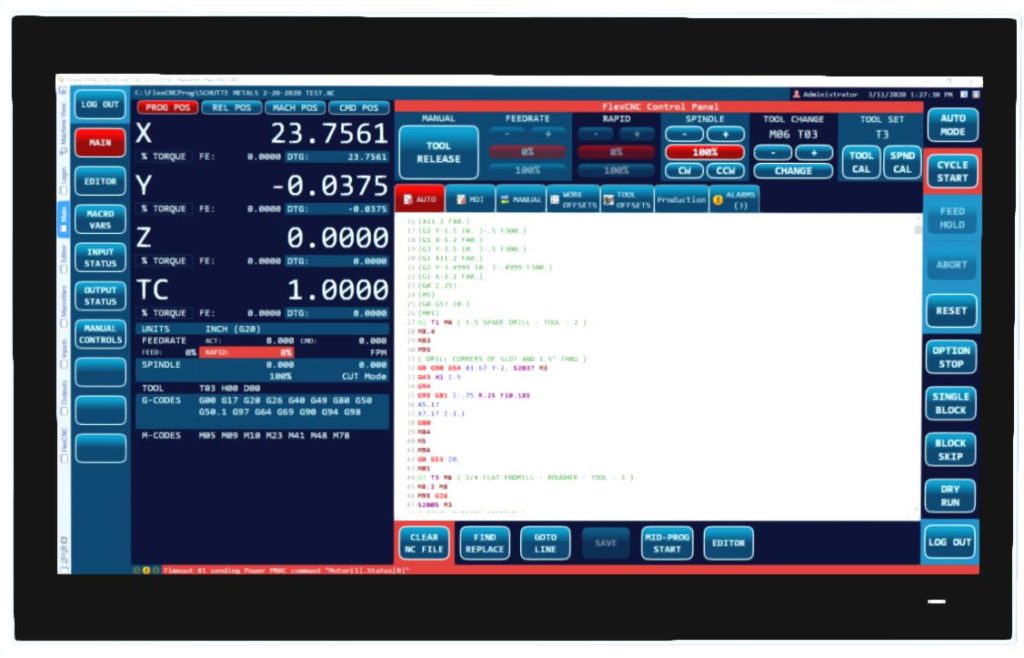

The Omron FlexCNC Control + Hand Pendant

The Omron FlexCNC Control is designed and developed to allow ISO G & M-code programming for dynamic machining and is comparable to standard commercially available controllers like the Fanuc 31i. It includes the capability of integrating an optional 4th axis. An infinite read-ahead capacity allows the machine to flawlessly and smoothly machine 3D tool paths, smooth helices, and ramping tool paths.

The AMI5000 Remote Pendant is used as a Human Machine Interface (HMI). It uses EtherCAT communications technology to interface with the ANCA Motion Control System Software, allowing fast and flexible access for real-time control!

"The machine paid for itself in the first job, and put $30,000 in our pocket."

-SBS Precision Sheet Metal

Download Customer Case Study

- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here