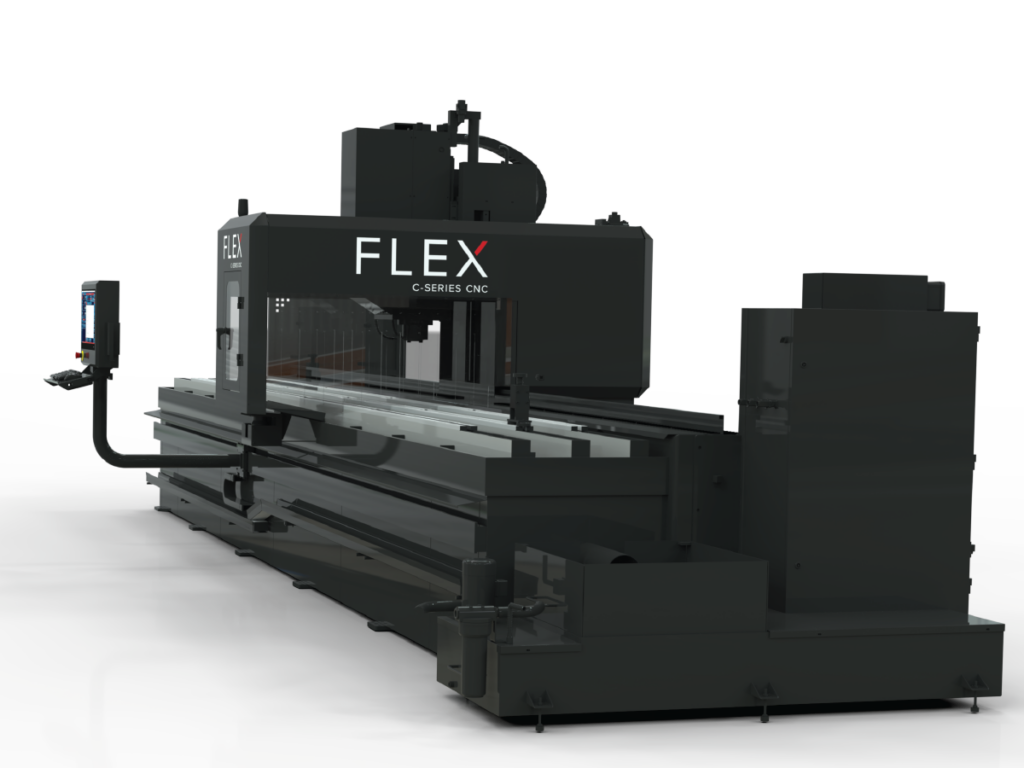

- Machining/ Turning

AUTOMATING MACHINING PROCESS WITH CNC FOR 3X THROUGHPUT

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

- WaterJet

IGEMS Software Training: 2D Basics for FlexJet Waterjets

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

- Beam Line

What is a Beam Line?

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

- FlexArm

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

- Stores

FLEXSWAG

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

- Machining/ Turning

AUTOMATING MACHINING PROCESS WITH CNC FOR 3X THROUGHPUT

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

- WaterJet

IGEMS Software Training: 2D Basics for FlexJet Waterjets

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

- Beam Line

What is a Beam Line?

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

- FlexArm

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

- Stores

FLEXSWAG

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag