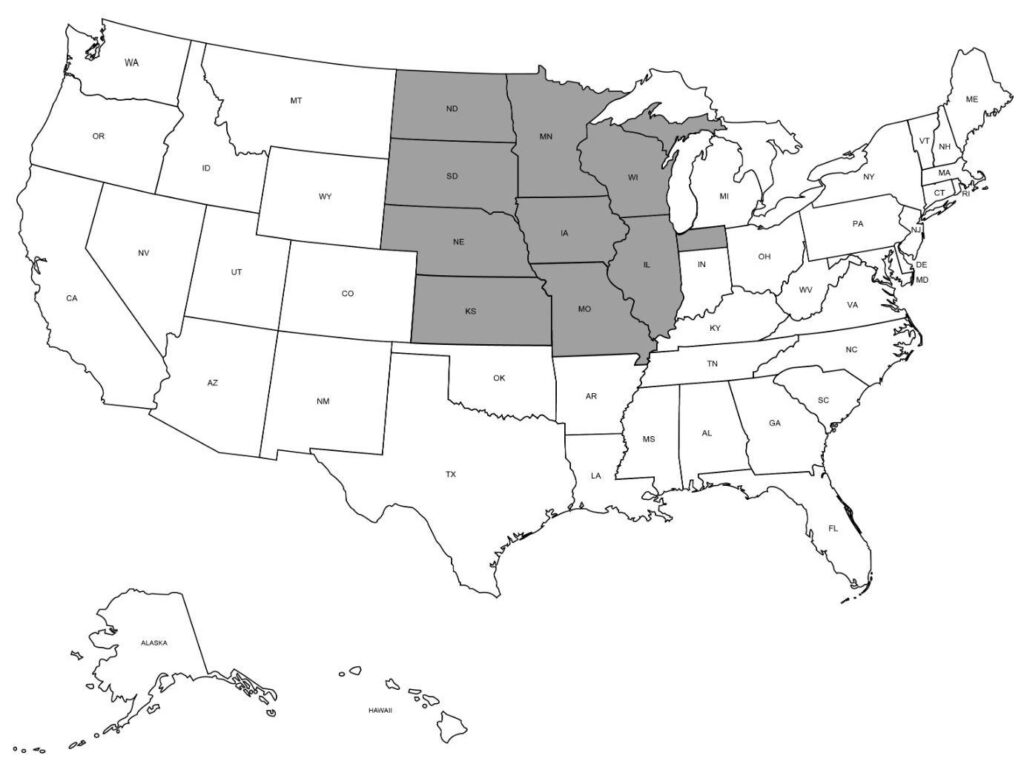

Flex Machine Tools is happy to announce Gladwin Machinery as the newest distributor of the FlexJet Waterjet. Gladwin has been a strong partner for Flex since 2019, bringing the FlexCNC to the areas they serve. Gladwin Machinery will represent the FlexJet in northern Indiana, Illinois, Wisconsin, Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, and Kansas.

Gladwin Machinery Territory

Logan Skelly, Midwest Sales Manager for Flex Machine Tools, said, “we are excited to expand on our existing relationship by partnering with them to bring the FlexJet to market. We are introducing technology that most people have never seen on a waterjet, which is great, but the second piece to the puzzle is showing a company how this technology can specifically benefit them. Gladwin has a top-notch team that we can trust to support that second piece. I know I can speak for the rest of us when I say we are proud to have them representing the Flex Machine Tools name.”

About Gladwin Machinery

Gladwin Machinery was established in 1973 in Minneapolis, Minnesota. The founders recognized an opportunity to provide quality metal fabricating equipment to an under-represented marketplace. They pooled together their resources and opened the first facility in Minneapolis. After years of steady growth, Gladwin has expanded to include office and warehouse showrooms in Milwaukee, Chicago, and Kansas City, with additional offices in Iowa, Nebraska, and Kansas City. Gladwin’s uninterrupted annual growth pattern has been primarily due to the business principles laid down by its founders, a great staff, and the ongoing commitment to making customer satisfaction the number one priority. Learn more about Gladwin Machinery Here.