Who Uses Waterjet Cutting Systems?

If you can imagine it, a waterjet will cut it. Who uses a waterjet cutting system? Waterjets are one of the most versatile cutting machines

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

The manufacturing landscape is constantly evolving. See how one company adapted by investing in new technology. Watch their full customer story below.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

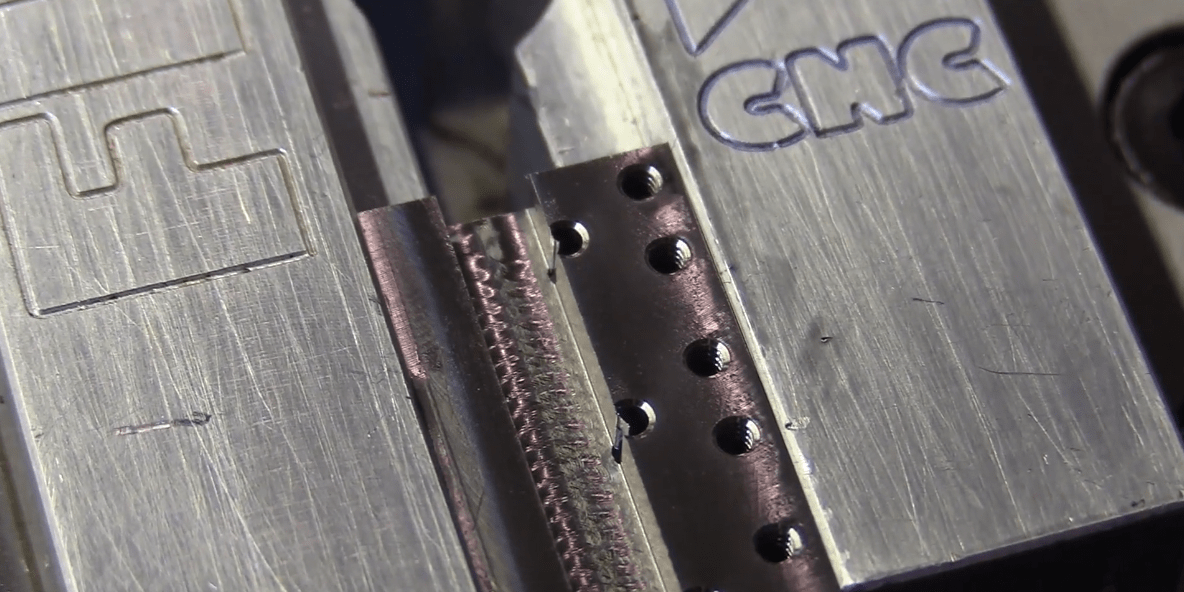

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

If you can imagine it, a waterjet will cut it. Who uses a waterjet cutting system? Waterjets are one of the most versatile cutting machines

What is a Beam Drill Line? Beam drill lines are important tools in medium to large-sized structural fabrication shops. Beam drill lines accurately drill holes

Flex Machine Tools partners with Westway Machinery We are pleased to announce that Flex Machine Tools has entered into a distribution partnership with Westway Machinery. Westway

Waterjet or laser? Many modern manufacturers are facing unique challenges, including maintaining flexibility while keeping costs low. The waterjet and the laser are both capable

If you’re a fabricator new to CNC technology, you may be wondering where to start when purchasing the right machinery for your needs. Two popular

Watch the video of this application at the bottom of this page. We had a customer looking for a torque reaction solution that could counterbalance

Torque Reaction Arms or assembly arms are commonly used in a variety of manufacturing environments. They take the tool weight and torque out of the operator’s

Watch the video of this application at the bottom of this page. We had an end-user out of California interested in seeing if the FlexArm

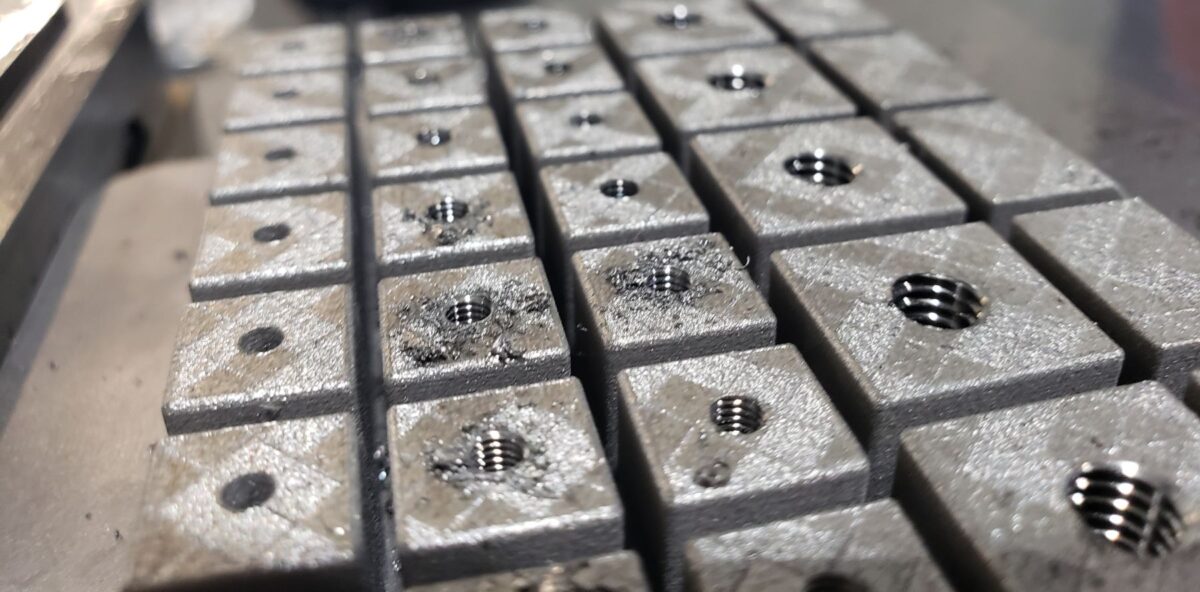

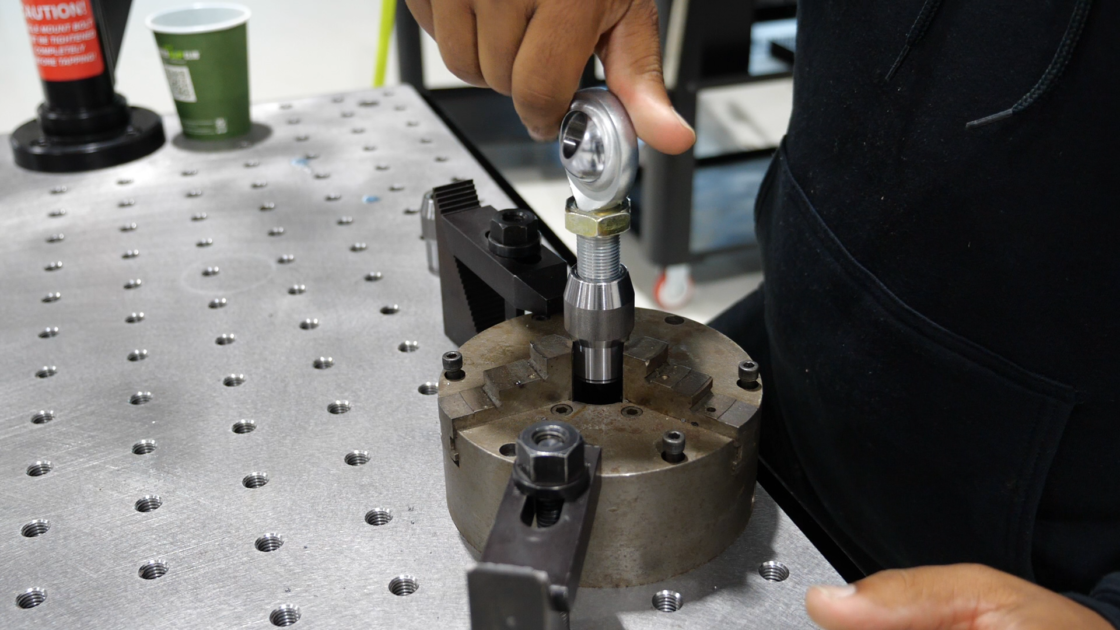

Tangible Solutions out of Fairborn, Ohio recently contacted us wanting to see if a FlexArm could handle tapping their small parts. They make 3D-printed titanium

Tapping can be challenging and frustrating, especially when broken taps and damaged threads come into play, leading to lower productivity and increased costs. However, various

Located in Valparaiso, Indiana, RockRabbit Guitars manufactures premiere guitar parts made of titanium. One of these parts requires 18 threaded holes. Up until recently, the

An end user recently approached Flex facing a common challenge: tapping plasma cut holes in A36 Steel. This particular end user is a general fabrication

Brad Jacob, from the BasementShopGuy YouTube channel, tested the FlexArm tapping arm against the Bridgeport in a time comparison demonstration. He wanted to see if the addition of a

An end-user out of North Carolina was looking for a more efficient way to tap their parts. They wanted to see how the FlexArm could

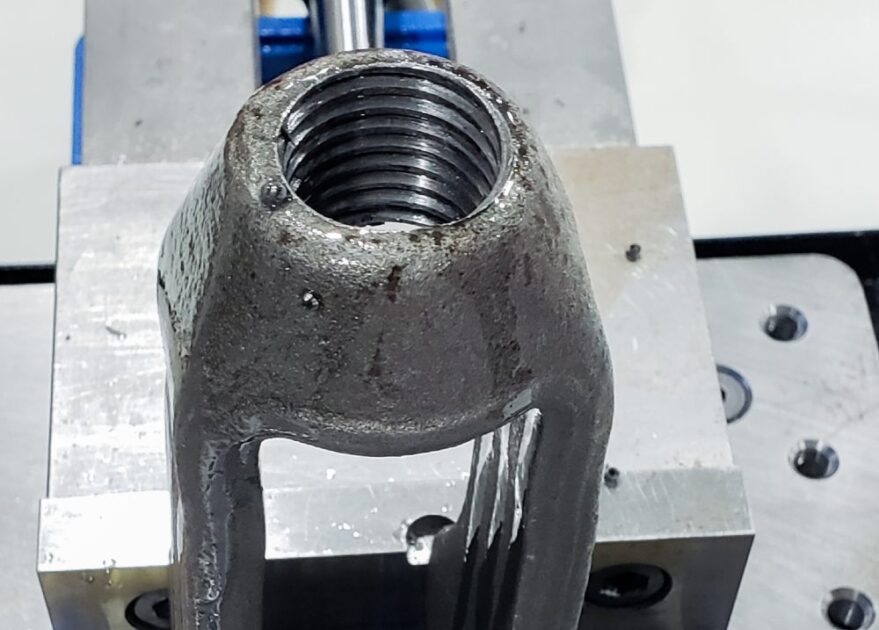

Watch the video of this application at the bottom of the page. A customer from Trotwood, Ohio, needed to tap precise and consistent NPT threads

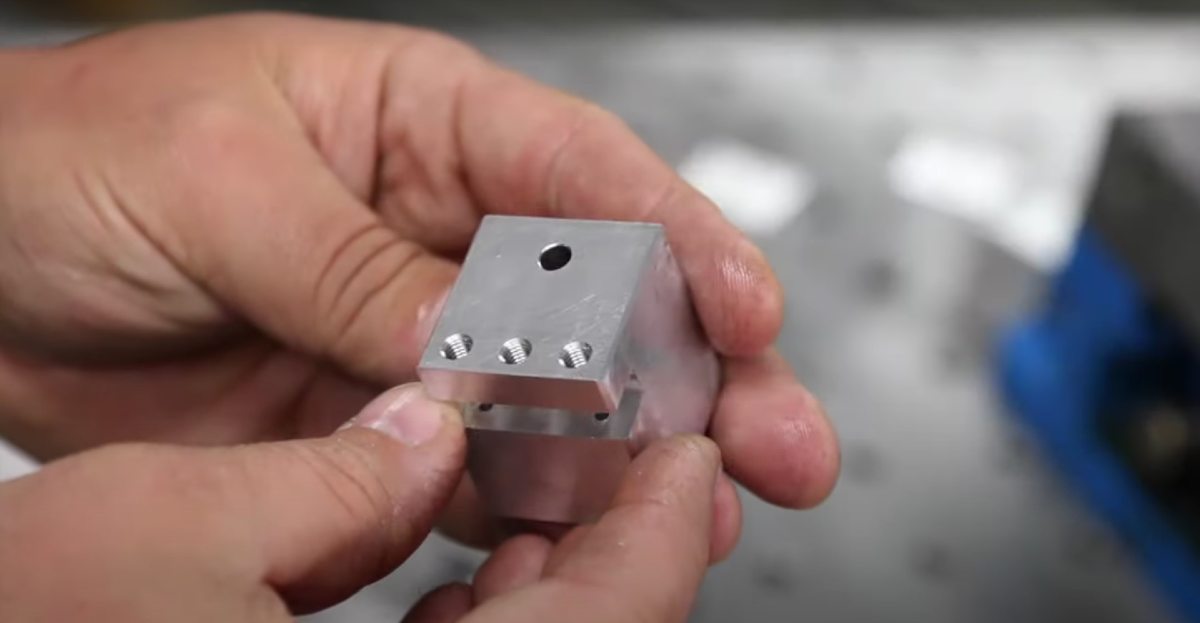

One of our distribution partners had an end-user that was interested in trying a FlexArm. The end-user, Magnum Precision Machines, is a job shop that

We had a customer send in some nuts for us to tap, so we put the GH-60 Hydraulic FlexArm tapping solution to the test.

Watch the video of this application at the bottom of the page. An end-user reached out to us looking for a better tapping solution to

Watch the video of this application at the bottom of the page. Here is an example of a very simple torque reaction solution. A customer

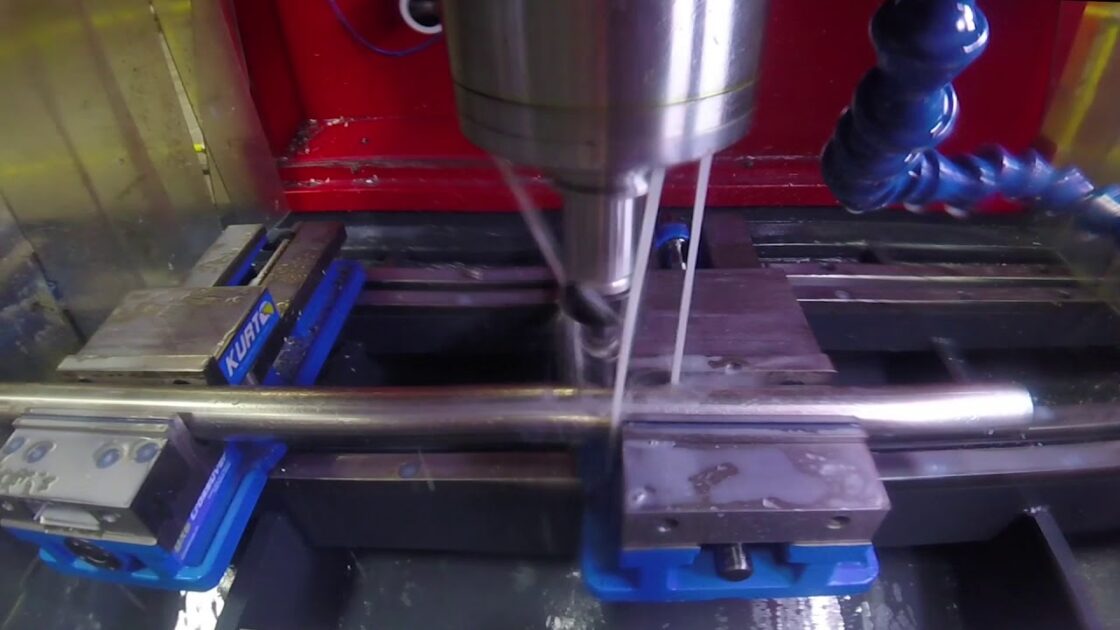

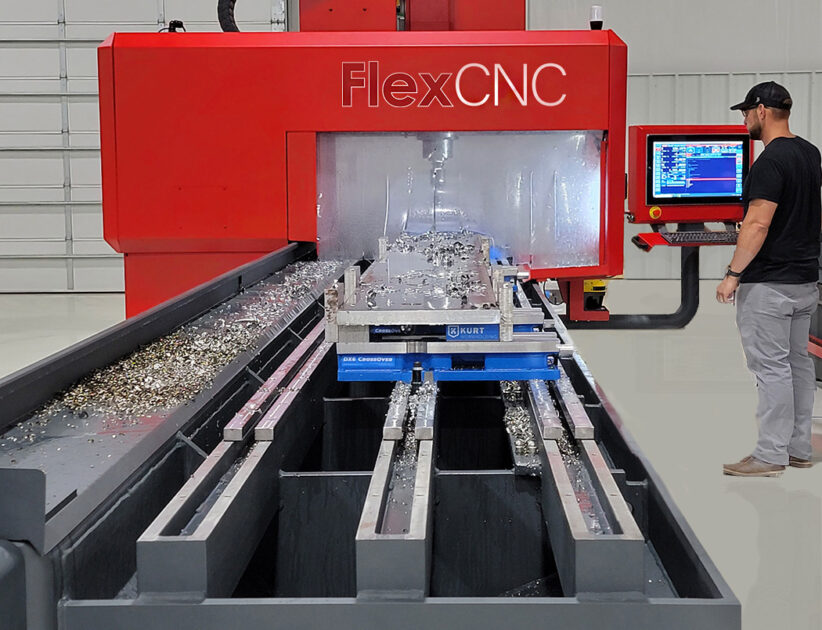

“We use the FlexCNC for two very specific uses, one of which we had an old machine for and another that we use to do by hand.

A prospect reached out to us because they were interested in trying out one of our tapping arms. PowerBuilt Material Handling Solutions, out of Bellefontaine,

In the world of metalworking, precision and efficiency are paramount. Threading holes accurately and consistently is essential for ensuring the integrity and performance of manufactured

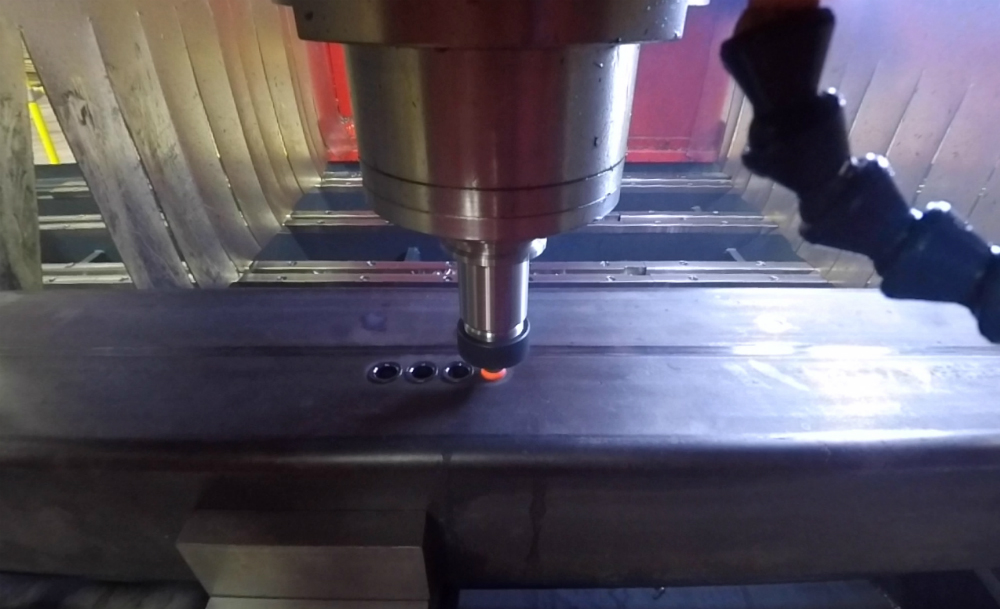

“As a manufacturer of architectural railing systems and components, R&B Wagner, Inc. is always looking for the best way to fixture and machine long lengths

When faced with production tapping, having the right tool for the job can save both time and money. Here is one situation where the FlexArm

CNC machinery can have problems arise, and some of these problems are more common than others. When these problems occur, FlexCare+ steps in to get them resolved

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

Petty Welding is a fabrication shop in Knoxville, Tennessee, that focuses on welding, fabrication, custom-iron work, and on-site repair. They’ve been in business for 11 years,

Watch the video of this application at the bottom of this page. A customer contacted us interested in an arm that could counterbalance a

Flex Machine Tools is excited to introduce a new offering to its line of ergonomic balance arms: the FlexArm B-33. The B-33 Zero-Gravity Balance Arm is a larger

Today, US manufacturing is widely misunderstood, especially among young people. Manufacturing remains central in the world economy yet is seen as an outdated and dying