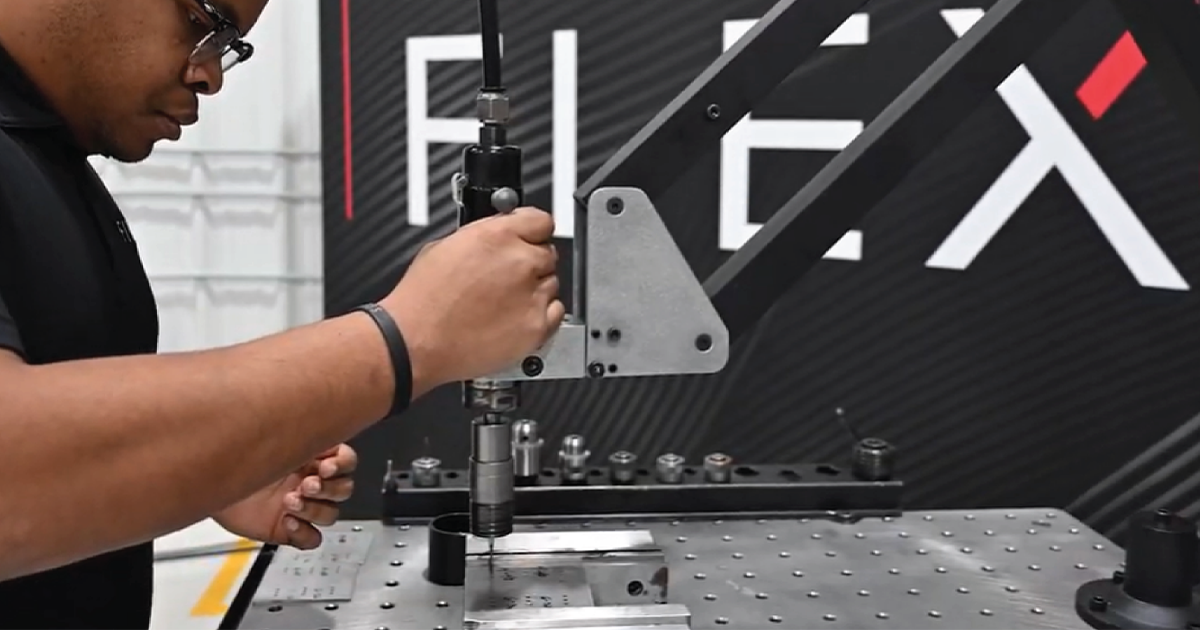

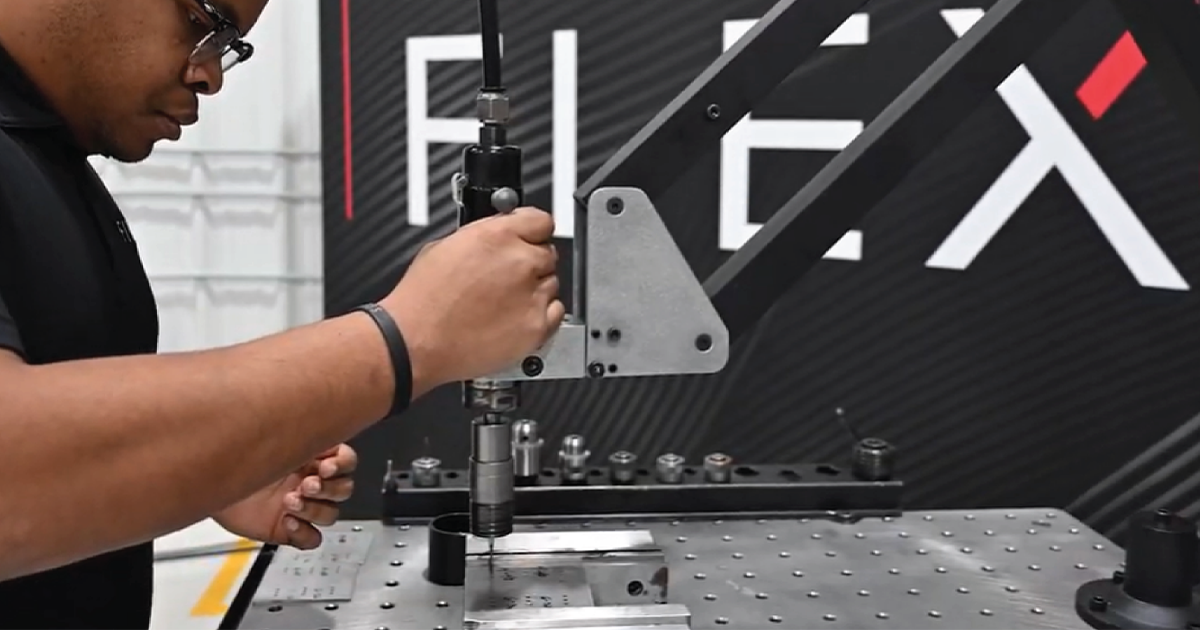

FlexArm S36 Tap Test for Stainless Steel Laser-Cut Parts

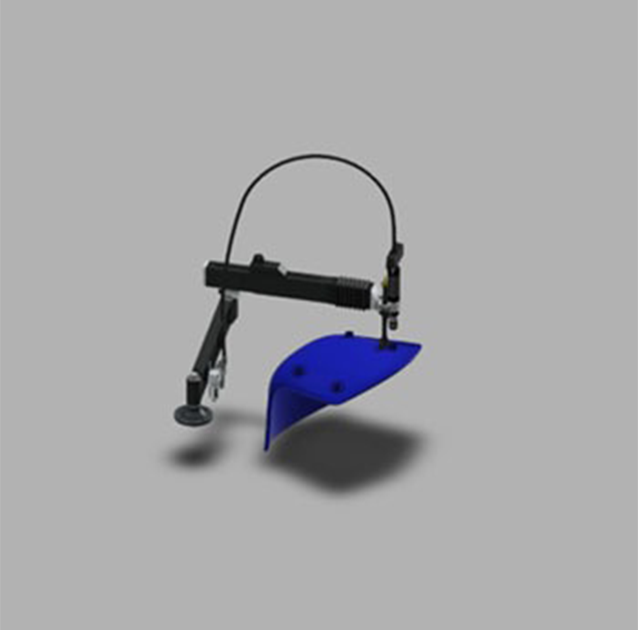

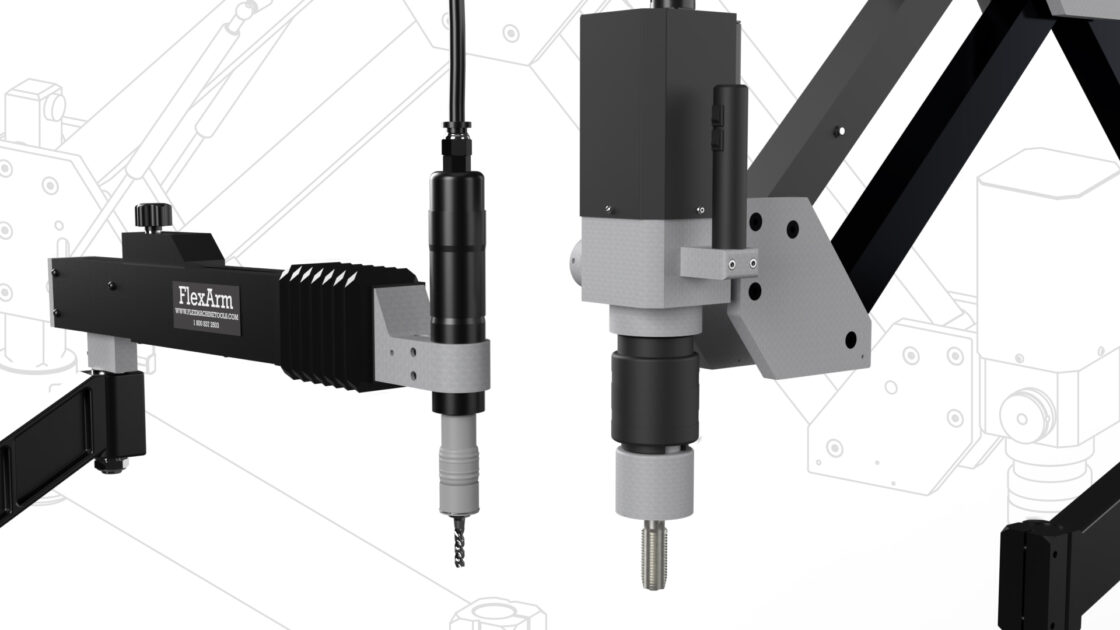

Stainless Steel Tap Test with the FlexArm S36 Tapping Arm In this tap test video, Max at Flex Arm demonstrates the FlexArm S36 tapping arm

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

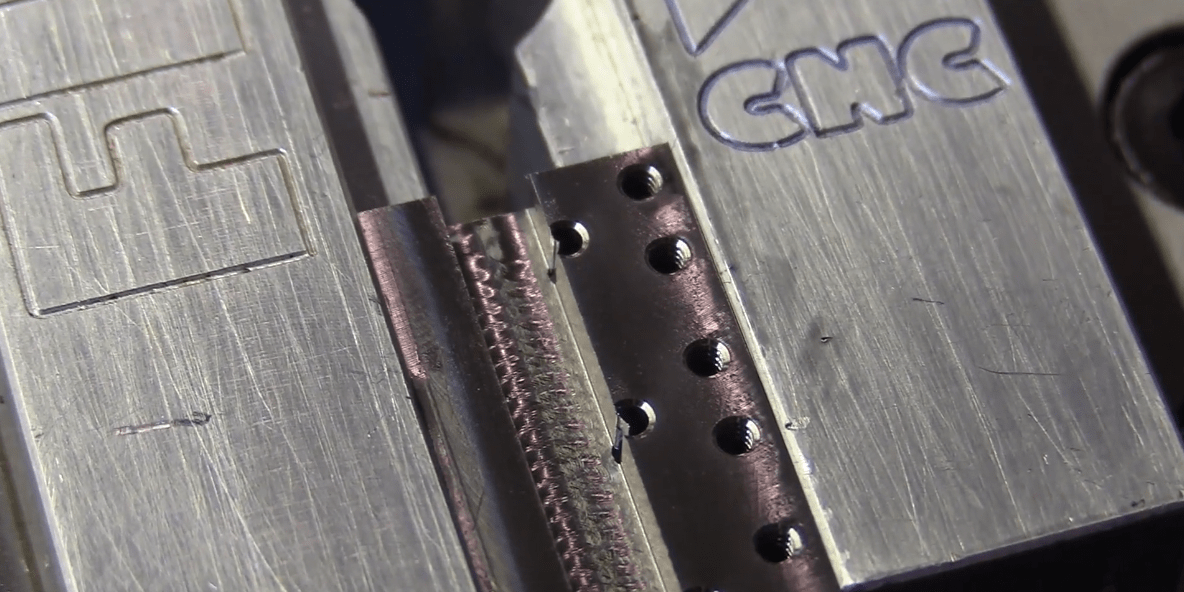

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

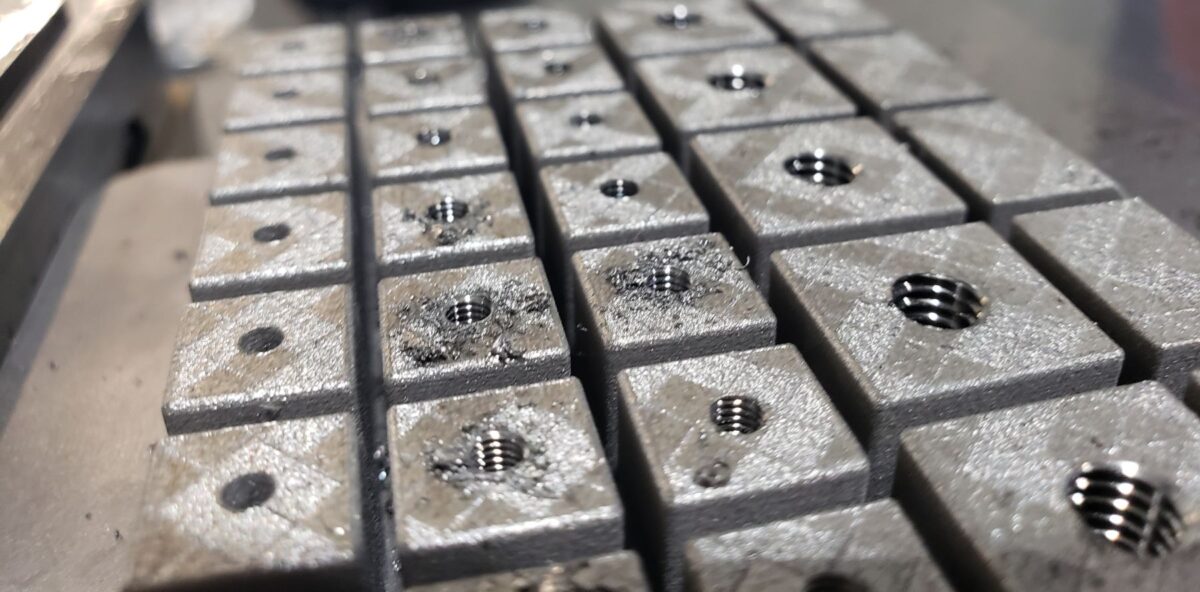

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Stainless Steel Tap Test with the FlexArm S36 Tapping Arm In this tap test video, Max at Flex Arm demonstrates the FlexArm S36 tapping arm

Automated Robotic Tapping Cell Case Study: Optimizing Workforce with Flex Automation Manufacturers today are under constant pressure to do more with less. Less labor, less

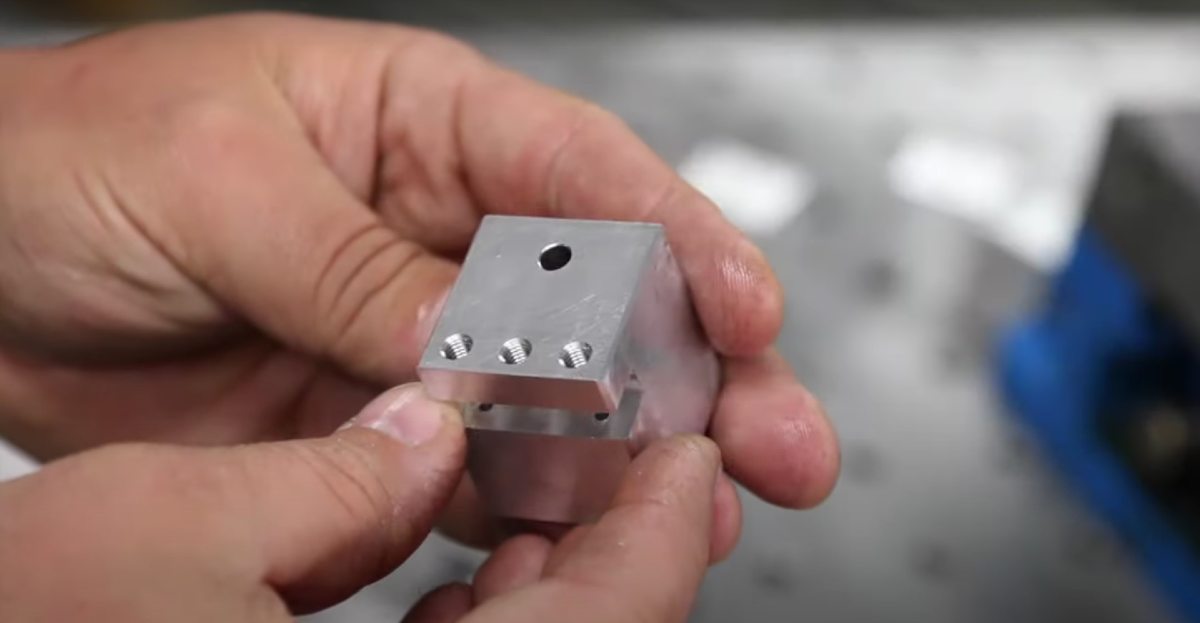

Tangible Solutions out of Fairborn, Ohio recently contacted us wanting to see if a FlexArm could handle tapping their small parts. They make 3D-printed titanium

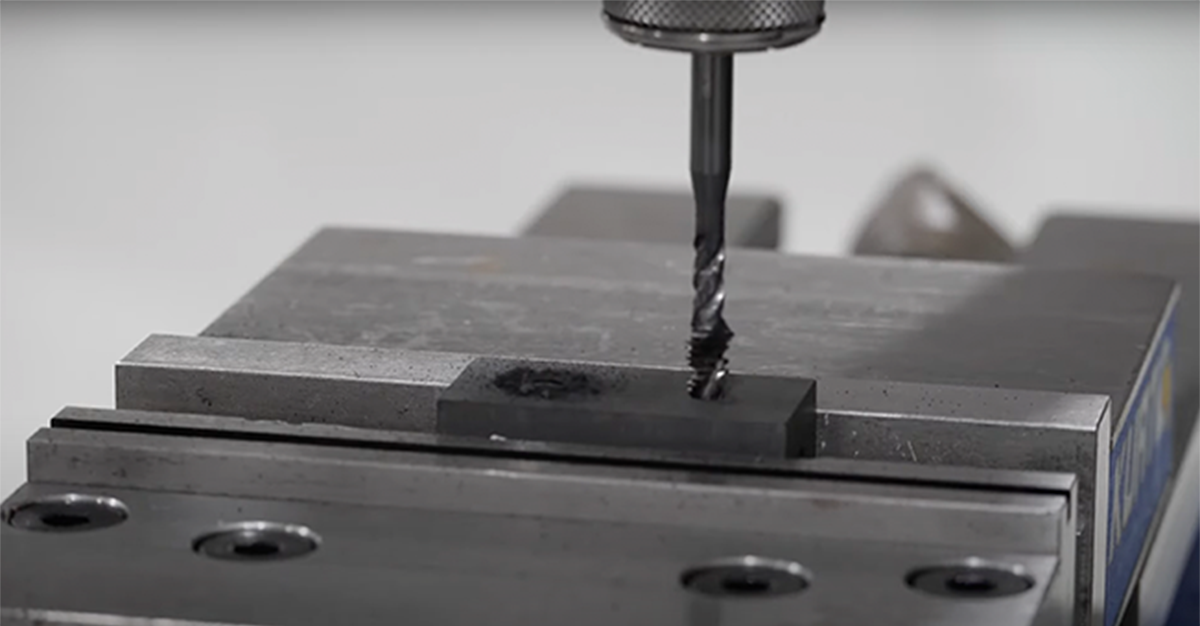

Tapping can be challenging and frustrating, especially when broken taps and damaged threads come into play, leading to lower productivity and increased costs. However, various

Located in Valparaiso, Indiana, RockRabbit Guitars manufactures premiere guitar parts made of titanium. One of these parts requires 18 threaded holes. Up until recently, the

Brad Jacob, from the BasementShopGuy YouTube channel, tested the FlexArm tapping arm against the Bridgeport in a time comparison demonstration. He wanted to see if the addition of a

An end-user out of North Carolina was looking for a more efficient way to tap their parts. They wanted to see how the FlexArm could

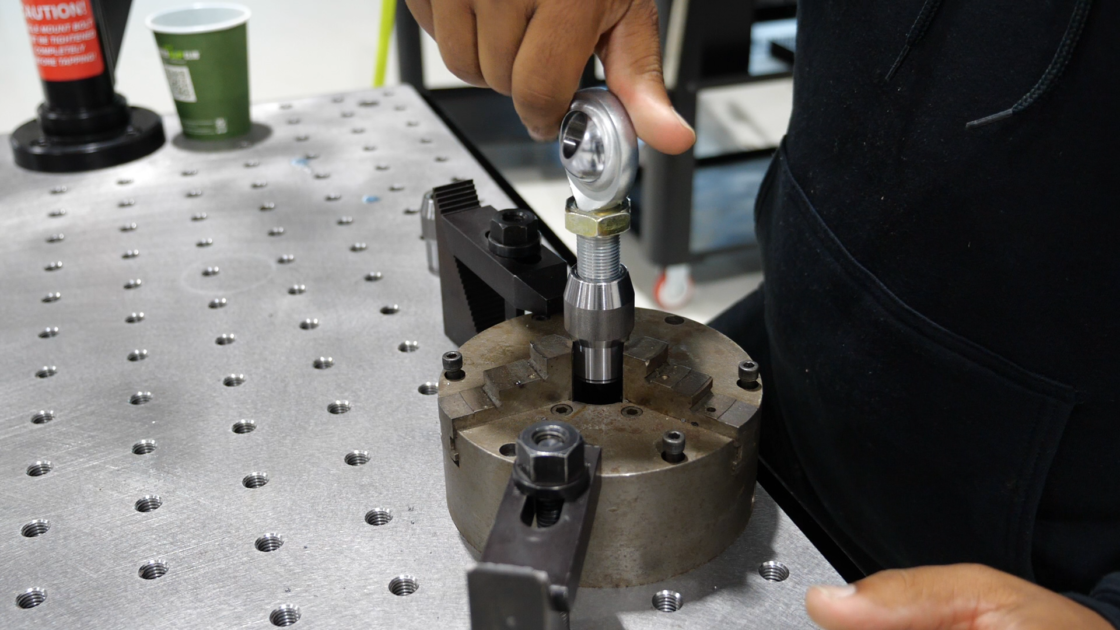

Watch the video of this application at the bottom of the page. An end-user reached out to us looking for a better tapping solution to

In the world of metalworking, precision and efficiency are paramount. Threading holes accurately and consistently is essential for ensuring the integrity and performance of manufactured

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

Installing threaded inserts by hand can be time consuming and inaccurate. One of our customers faced this problem when it came to installing inserts into

Tapping small holes can be a challenge. You are guaranteed to break taps whether you tap by hand, with a cordless drill, or in a

HOW TO TAP GRAPHITE? Tapping graphite, a notoriously soft and brittle material, presents a significant challenge. Finding reliable information on how to tap graphite is

When it comes to choosing the right tapping arm, the decision depends on several factors, including the specific application requirements, production volume, and budget. Here