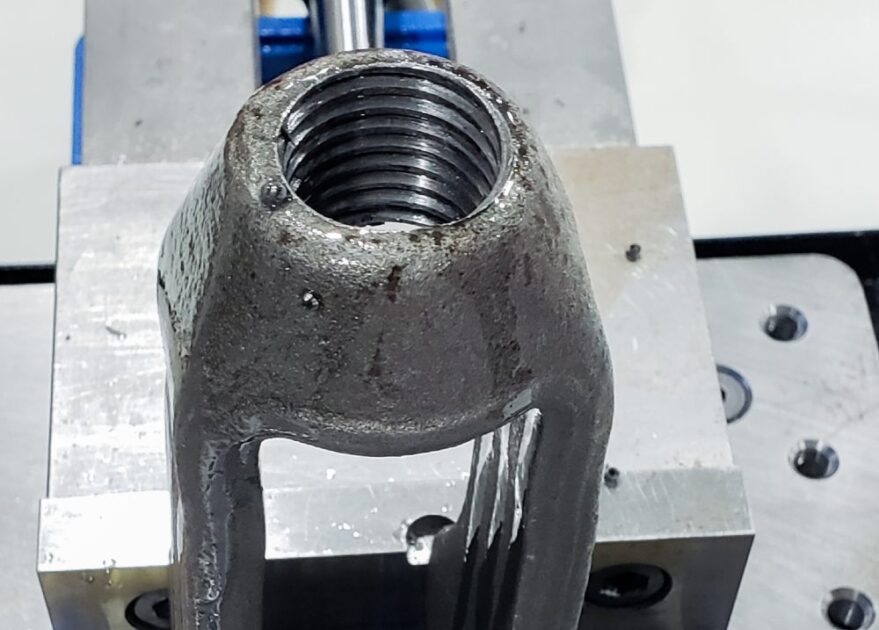

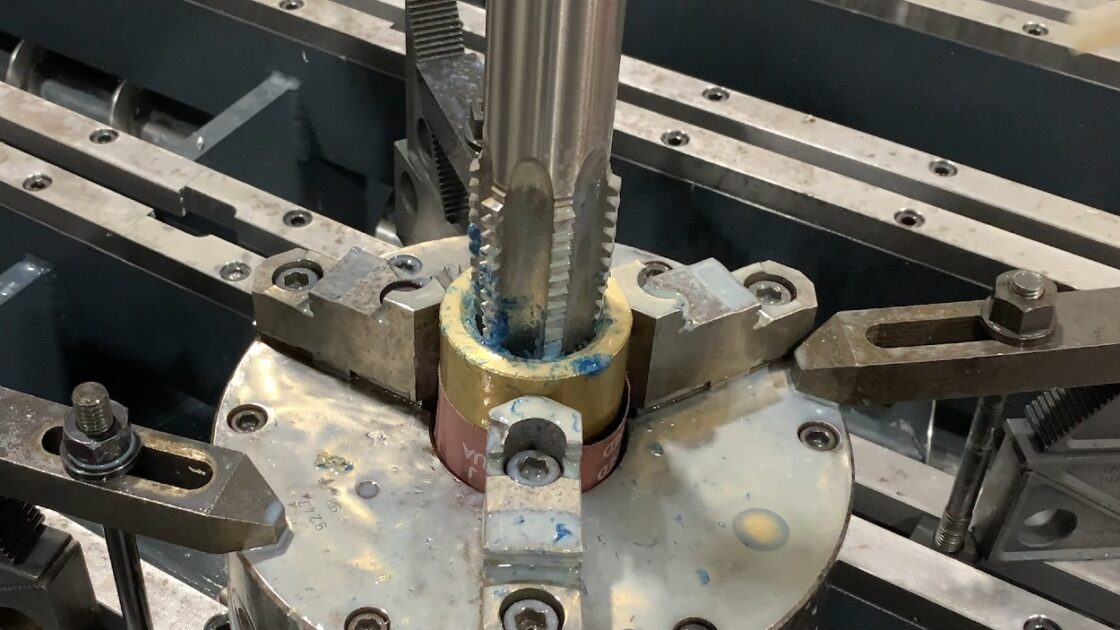

Chasing Threads With A 3″ Tap

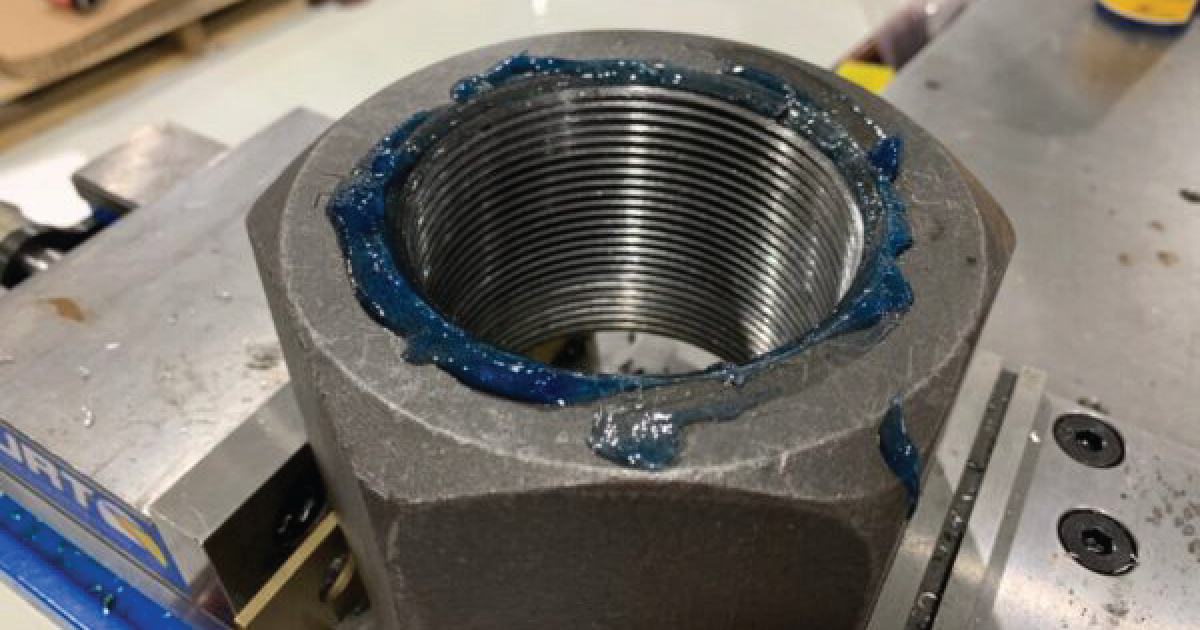

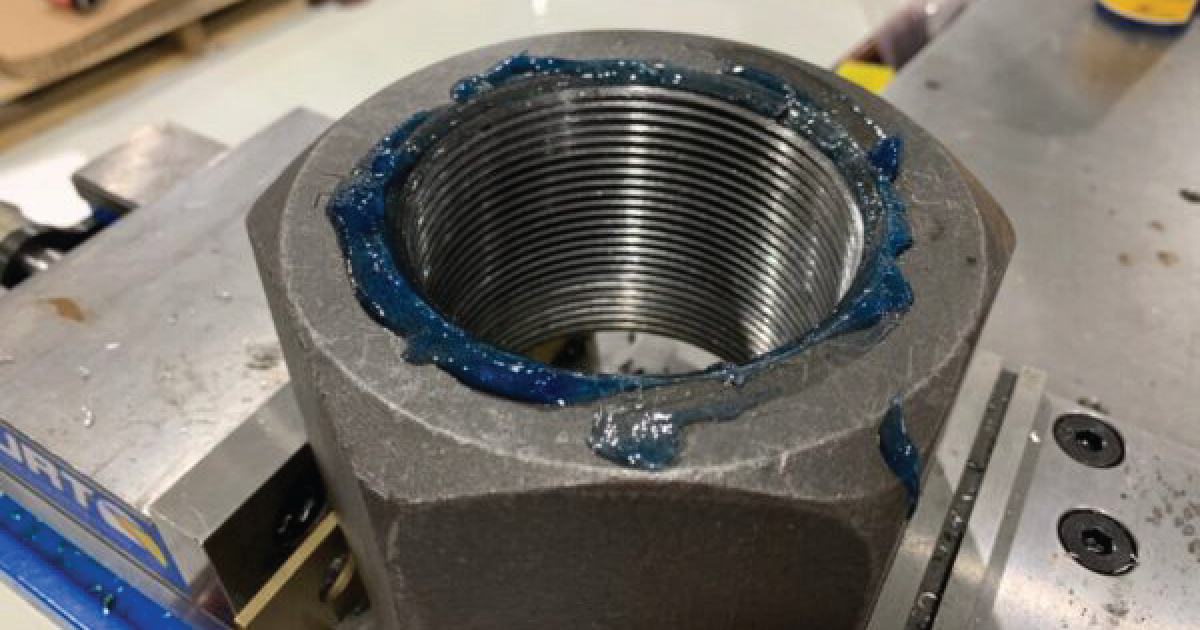

The team at Flexitallic was looking at the GH-60 Hydraulic Tapping Arm to see whether or not it’d be able to handle some huge tapping

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

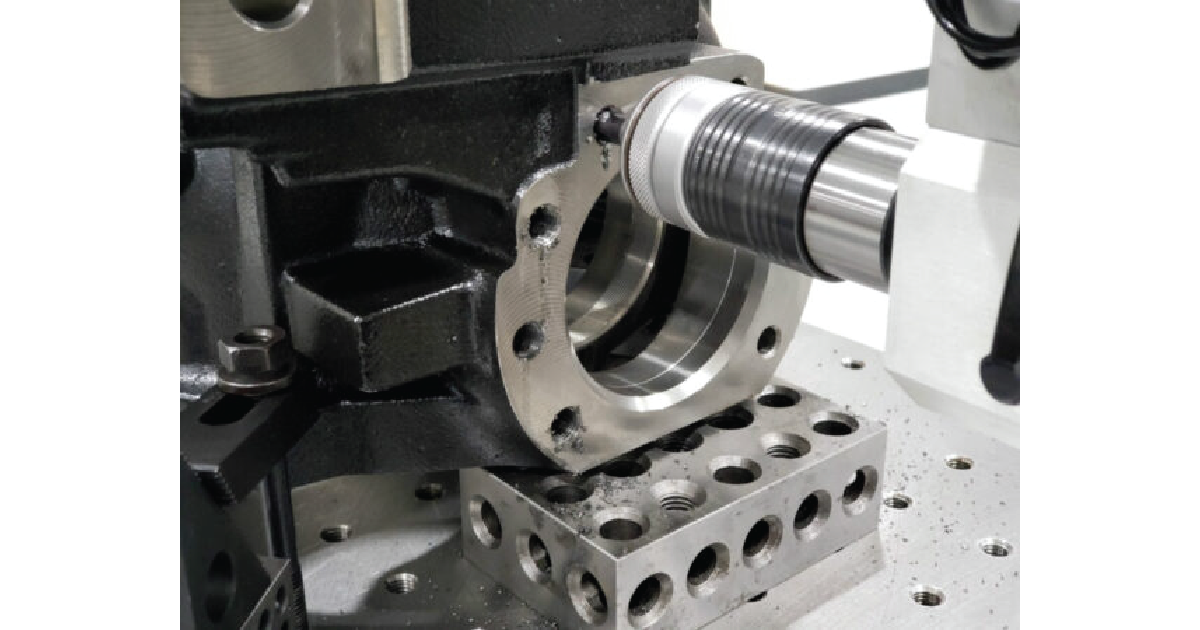

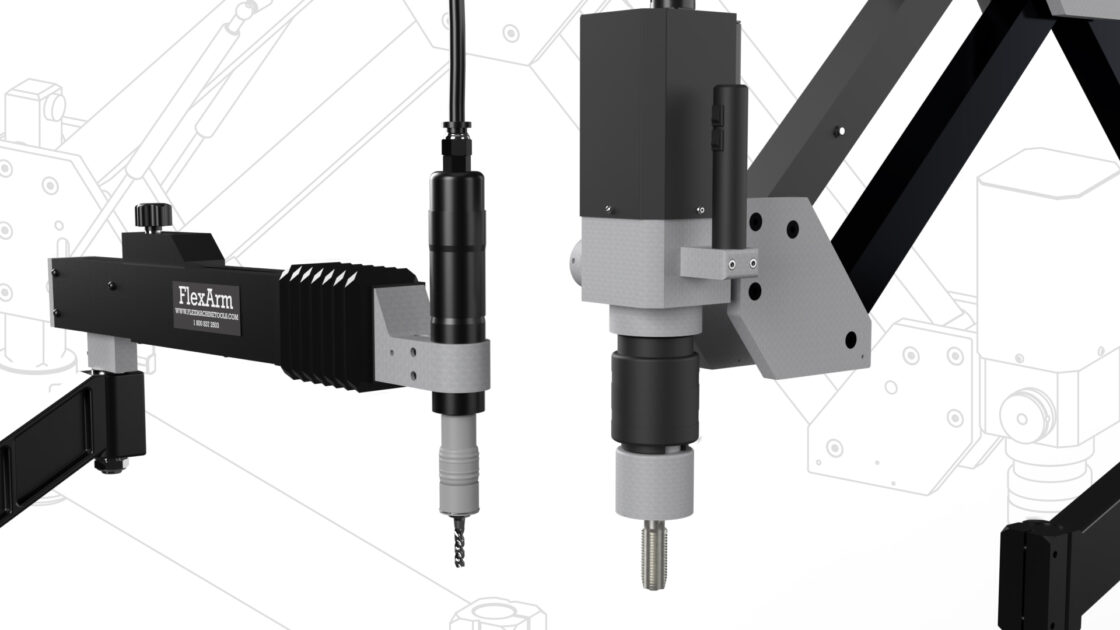

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

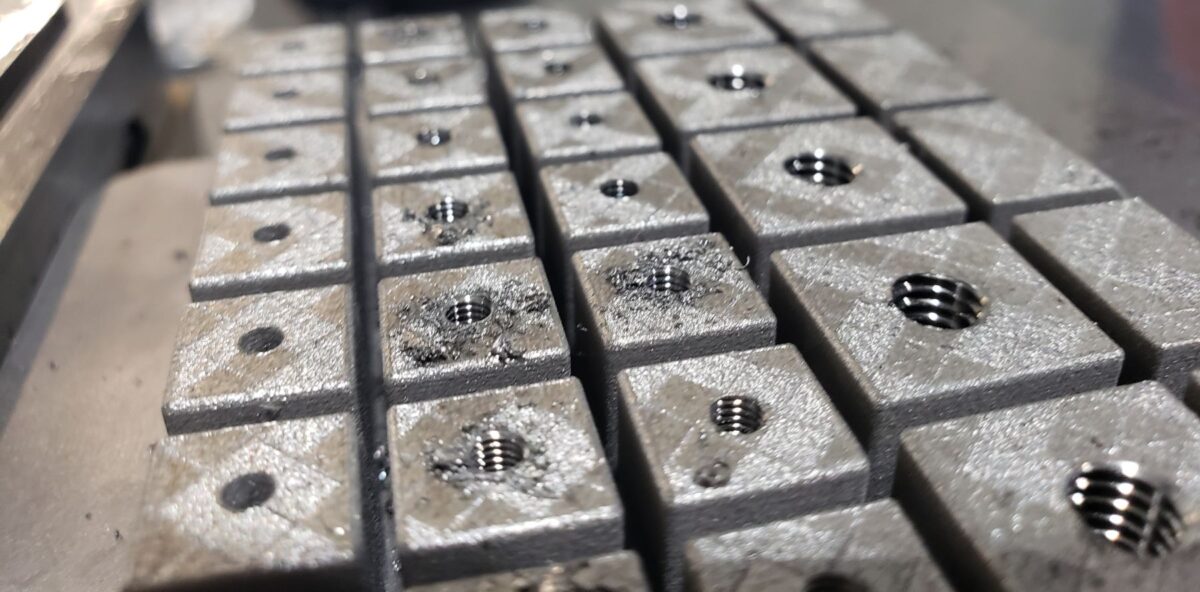

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

The team at Flexitallic was looking at the GH-60 Hydraulic Tapping Arm to see whether or not it’d be able to handle some huge tapping

Active Alloys is a full-service steel fabrication shop in Chicago, Illinois. They specialize in designing and fabricating architectural elements, machines, furniture, and vehicles. William Tellmann and

An end-user out of Indiana was interested in taking their tapping operations offline. They offer CNC services for customers in the automotive, heavy truck, and

Watch the video of this application at the bottom of this page. We had an end-user out of California interested in seeing if the

Tangible Solutions out of Fairborn, Ohio recently contacted us wanting to see if a FlexArm could handle tapping their small parts. They make 3D-printed titanium

Tapping can be challenging and frustrating, especially when broken taps and damaged threads come into play, leading to lower productivity and increased costs. However, various

An end-user out of North Carolina was looking for a more efficient way to tap their parts. They wanted to see how the FlexArm could

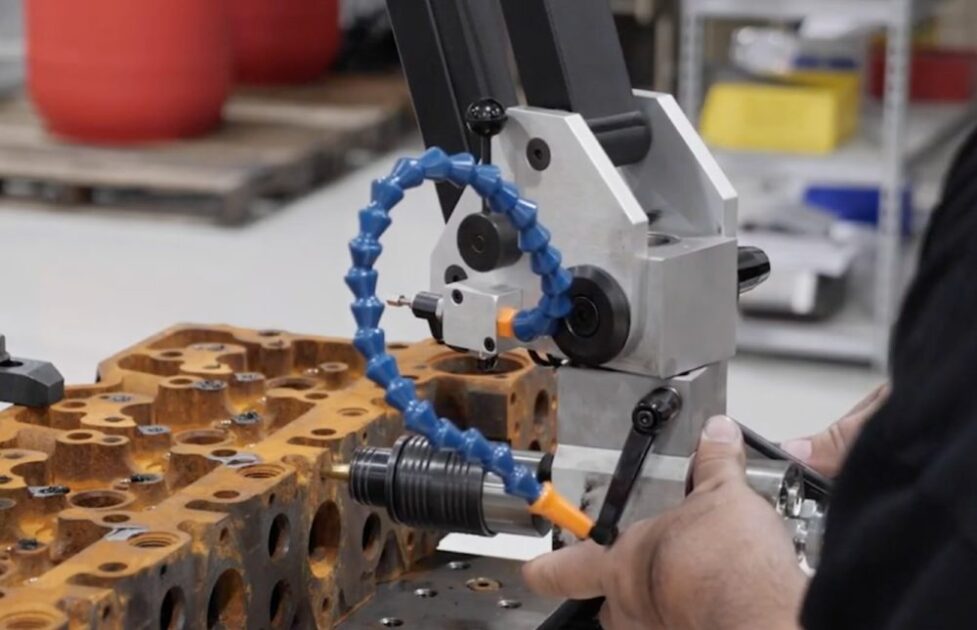

Watch the video of this application at the bottom of the page. A customer from Trotwood, Ohio, needed to tap precise and consistent NPT

One of our distribution partners had an end-user that was interested in trying a FlexArm. The end-user, Magnum Precision Machines, is a job shop that

We had a customer send in some nuts for us to tap, so we put the GH-60 Hydraulic FlexArm tapping solution to the test.

A prospect reached out to us because they were interested in trying out one of our tapping arms. PowerBuilt Material Handling Solutions, out of Bellefontaine,

When faced with production tapping, having the right tool for the job can save both time and money. Here is one situation where the FlexArm

A prospect out of Monroe North Carolina reached out to FlexArm because they were looking for an alternative tapping method that would eliminate tap breakage.

HOW TO THREAD REBAR? Rebar is found in nearly every concrete and masonry structure in the United States. Global Market Insights reports that the United States produced

Lindsay Machine Works, Inc. has owned a FlexArm for 15 years. They recently purchased a hydraulic arm to handle larger tap capacities. See how many holes they can

Live Streaming Info is Below FlexArm has collaborated with Launcher, a startup based in New York City, to help them develop the world’s most efficient rocket

Watch the video of this application at the bottom of this page. A recent prospect reached out to the FlexArm team looking for a better

When it comes to choosing the right tapping arm, the decision depends on several factors, including the specific application requirements, production volume, and budget. Here

D&J Precision is a machine shop that builds crate engines and cylinder heads for the diesel performance industry. They reached out to FlexArm, looking for a better

Shops all across the country are continuously looking for ways to improve their processes. An Ohio manufacturer specializing in custom roll threaded products was looking

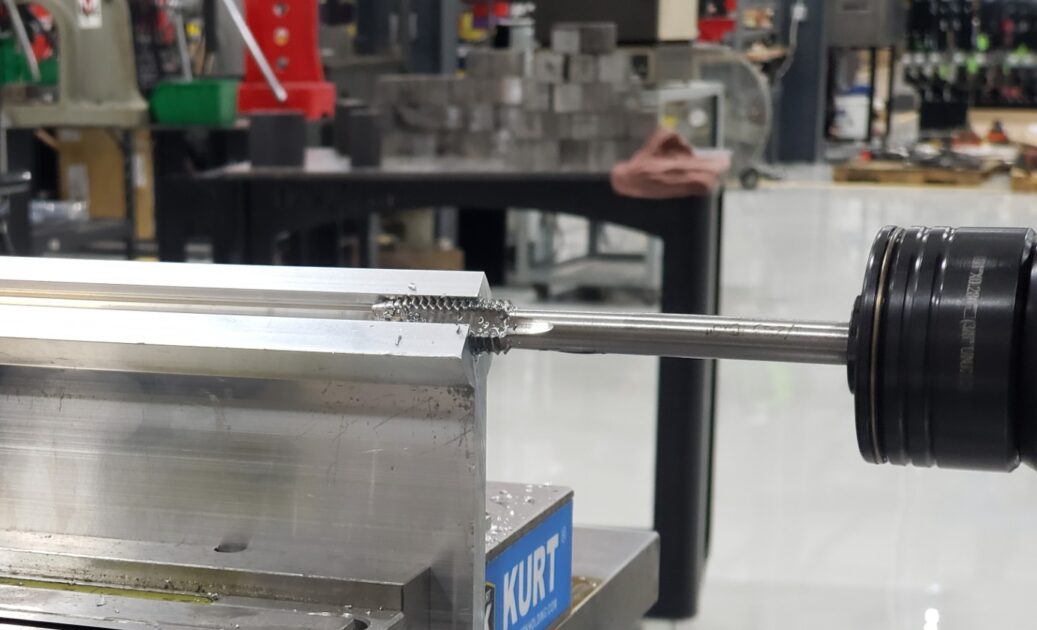

A prospective customer contacted us looking to free up their 5-axis machines by tapping offline. For this test, we were tapping into aluminum with a