- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here

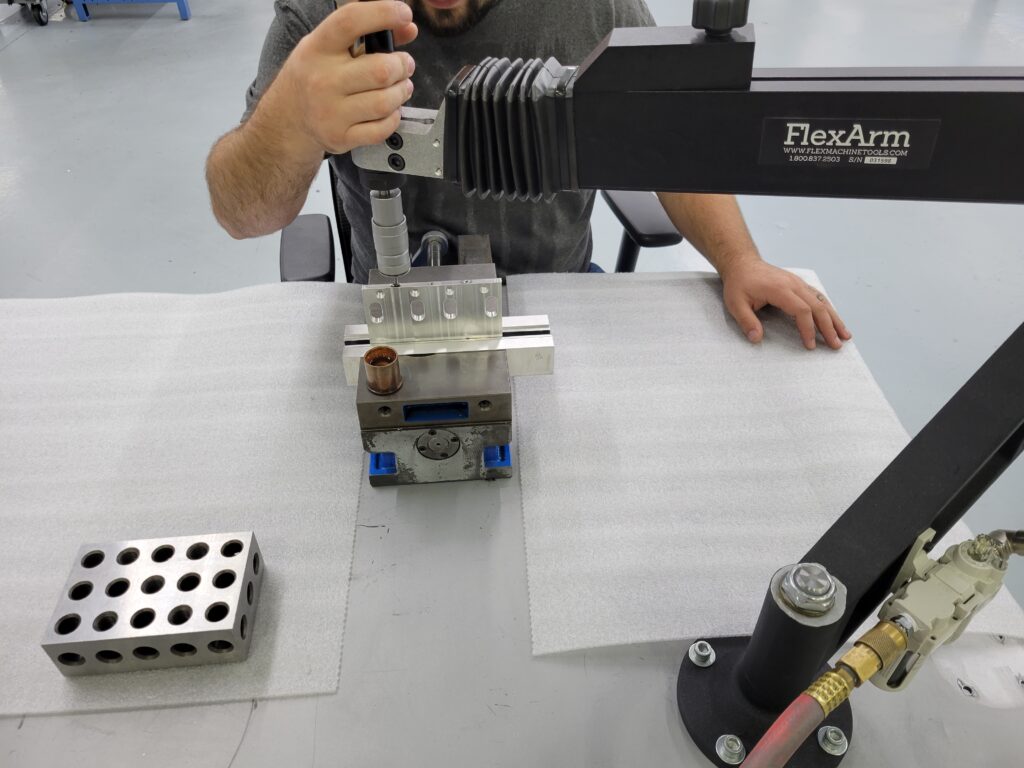

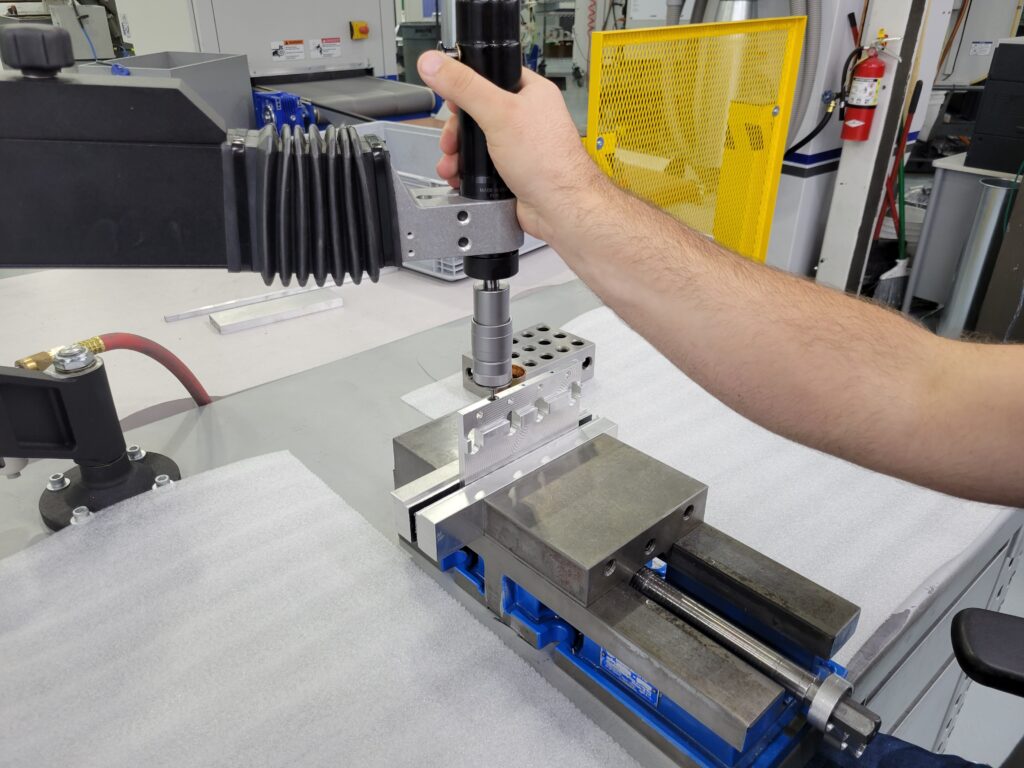

Customer Spotlight: Crystal Group Inc.

Crystal Group, Inc. is a leading provider of high-performance, rugged compute solutions for defense, government, and industrial markets. Founded in 1987, this small, employee-owned business specializes in designing, customizing, building, and testing rugged servers, embedded computers, networking devices, displays, and data storage for high reliability in harsh environments. Their integrated solutions meet or exceed IEEE, IEC, and military standards, including MIL-STD-810, 167-1, 461, and MIL-S-901, to bring seamless, real-time artificial intelligence, autonomy, and cybersecurity to demanding edge applications.

What is your company mission or brand promise?

Our mission is to provide high-quality products and services, quickly and flexibly, with unparalleled customer support.

What are some projects you've worked on that you are the most proud of?

We have full compute solutions on high-profile military programs, like the B2 Bomber, THAAD, JPALS, CANES, and SEWIP. We’ve also had a lot of recent success with autonomous applications, like autonomous semi-trucks.

What makes your company stand out?

We give our customers the exact solution to meet their needs, and we can do this fast. We also take care of them long past the sale if an upgrade or a part needs replacing. We put the customer first and make sure they stay mission-ready.

How did you come to learn about FlexArm?

A web search brought us to FlexArm while looking for reputable tapping arms.

What ultimately made you decide to purchase a FlexArm?

We chose to go with FlexArm because of the ability to work on plastic and aluminum parts, reviews of quality, ease of use, customer support, and added value to our CNC department. With our use and cost savings, we estimate the FlexArm to pay for itself in less than a year and a half.

How has the FlexArm improved your operations?

FlexArm is used regularly to quickly fix first-run parts that may have shallow threads, undersized counter-sinks, and undersized holes. It has also immensely shortened our turn-around time for re-working parts for customer-requested changes in these areas. This saves several hours of reworking by hand. In one case of modifying a purchased part. We reduced our rework time by almost 90% compared to doing it by hand.

Related Topics

Five Dynamic Uses for the FlexCNC

The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC can perform various functions for numerous specialized projects, saving you space and money with...

Read MoreFlex Machine Tools Launches the new Flexible Tapping Center

Flex Machine Tools is excited to launch a new product that will revolutionize your workshop: the Flexible Tapping Center (FTC). This specialized machine is equipped with superior precision, innovation, and performance to produce quality products for your business. Typically,...

Read More

Take the Risk Out of Choosing Tapping Arms:

Free Tap Test by FlexArm

When selecting machinery for your company, deciding what tools will work best for your product can be overwhelming, and it can feel like a risk when you need to know if the product you bought will be the right...

Read More