- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here

Improving Workplace Safety with Custom Tool Balancer for Hytorc LST-2000 Torque Tool

The Problem with Heavy Tools

Bolting applications often require heavy tools such as torque wrenches and impact wrenches to achieve the appropriate level of tightness for bolts. However, handling these tools can be challenging and even dangerous. Fortunately, tool balancer arms can be used to counterbalance the tool’s weight and reduce physical strain, providing added support and balance for greater precision and control.

Recently, the FlexArm engineering team provided a counterbalancing solution for a customer with a unique application. They sought to improve workplace safety by finding a counterbalance solution for a 30-pound Hytorc LST-2000 electric torque tool. They use the tool atop a scissor lift, and this solution prevents the tool from being accidentally dropped off of the lift and causing serious injury. Additionally, the tool balancer reduces operator fatigue, which is known to lead to errors and accidents.

FlexArm's Custom Solution

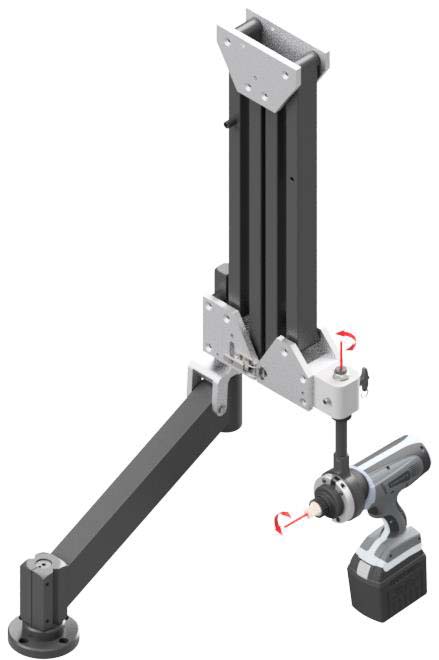

To hold the Hytorc LST-2000 tool, FlexArm designed and manufactured a custom mount with the G-30 model arm. The custom arm is designed to counterbalance the tool’s weight and provide added support and balance, making it easier to handle. The mount securely clamps around the tool’s body using the exact dimensions of the tool for a perfect fit. The rotations about the vertical and horizontal axes (indicated by the arrows in Figure 1.) allow the operator to freely maneuver the tool as they desire.

FlexArm also provided additional components, including a latch to keep the parallel arms locked together and a rotation stop block to prevent swinging during transportation, making using the G-30 arm on a scissor lift easier.

Figure 1

The Benefits of Using a Tool Balancer Arm

FlexArm’s custom tool balance arm was a game-changer for the customer. It provides support and balance for the heavy tool, making it easier and safer to use. However, it’s important to remember that using heavy tools high in the air, such as on a scissor lift, comes with additional safety risks. Workers must ensure the tool is properly secured and follow all safety procedures to prevent accidents

FlexArm’s custom arms are a prime example of how specialized ergonomic solutions can improve efficiency and safety in the workplace. You know how challenging and dangerous it can be if you handle heavy tools. FlexArm’s custom tool balancer arms are tailored to meet specific application needs, making your work easier and safer. Contact us today. Our engineers would happily review your application to see how our tool balancer arms can benefit you.

Related Topics

Five Dynamic Uses for the FlexCNC

The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC can perform various functions for numerous specialized projects, saving you space and money with...

Read MoreFlex Machine Tools Launches the new Flexible Tapping Center

Flex Machine Tools is excited to launch a new product that will revolutionize your workshop: the Flexible Tapping Center (FTC). This specialized machine is equipped with superior precision, innovation, and performance to produce quality products for your business. Typically,...

Read More

Take the Risk Out of Choosing Tapping Arms:

Free Tap Test by FlexArm

When selecting machinery for your company, deciding what tools will work best for your product can be overwhelming, and it can feel like a risk when you need to know if the product you bought will be the right...

Read More