FLX-1365

Speed / Accuracy

Ballbar Circularity …………………< 0.003 in.

Acceleration ………………………………..0.5G

Maximum Traverse Speed …….. 1,800 in/min

Ballbar Circularity ……………… < 0.003 in.

Acceleration …………………….. 0.5G

Maximum Traverse Speed … 1,800 in/min

Standard Specifications

Hand Pendant

22″ Multi-touch Screen & Roll Around Control

Water Level Control: 4″ rise

Abrasive Hopper: 500 lb continuous fill

Material Support Slats: Steel

Electrical Requirements: 3 Phase, 480V

CAD-CAM Express

Optional Equipment

5-Axis Flexibility

Patent Pending Design allowing for faster more accurate cuts

FlexJet uses a Real 5-axis not a Focal Point Design:

- -Achieve taperless cutting with the novel 5-axis head

- -Utilize dynamic tangential following

- -Accurately cut difficult to reach areas

- -Cut any angle with no limits

- -Use any length nozzle

- -Easy to program

- -Easy to post

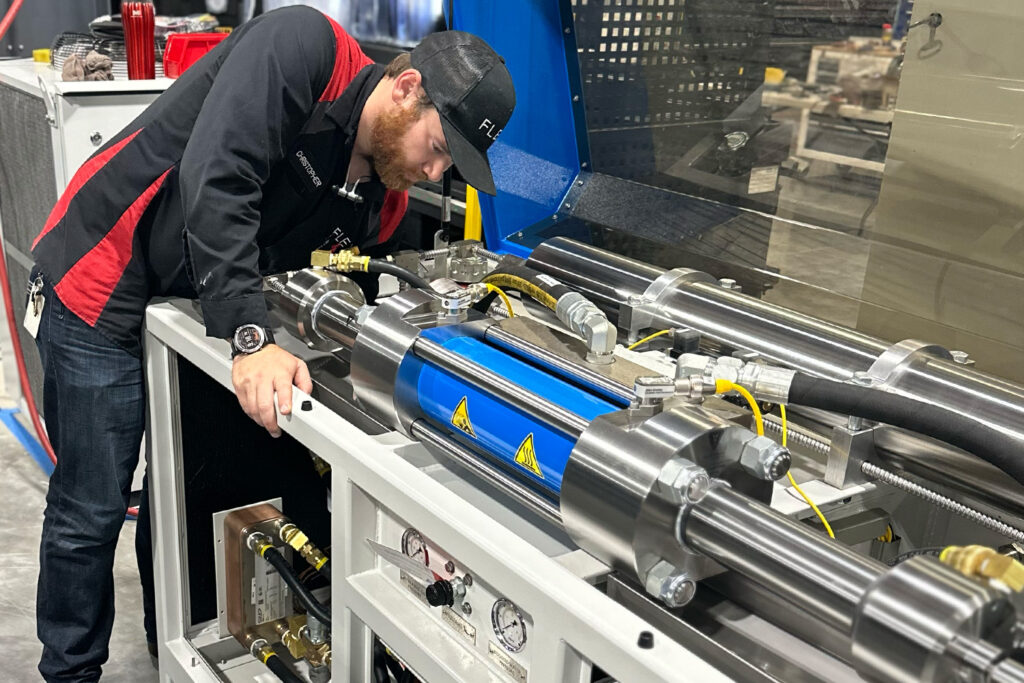

Designed for You

Engineered with user convenience in mind, the FLX waterjet showcases a thoughtful design that prioritizes easy maintenance. This user-friendly approach ensures an exceptional experience, increased productivity, and easy upkeep.

Robust Design

With its robust design, the FLX Waterjet offers enhanced reliability and reduced maintenance needs. The machine’s exceptional structural integrity guarantees long-term durability, resulting in minimal downtime and reduced repair expenses.

Unmatched Service

High production waterjet cutting requires responsive service when you need it. Whether remote or in-person, our highly skilled service team will react quickly to provide you with the level of support you desire.

100 % MANUFACTURED IN THE USA

WATERJET SERVICE

With Flex, we don’t just provide you with a service; we’re your dedicated partners in optimizing your productivity. Our approach revolves around your needs, guided by a team of seasoned service engineers who stand ready to deliver solutions and minimize downtime quickly. We understand the importance of keeping your machinery operational, which is why our nationwide network ensures expert assistance no matter your location. With over 20 years of accumulated experience, coupled with ongoing training, our service experts excel in tackling the ever-evolving challenges of the industry. And to ensure your equipment remains at its best, we offer comprehensive maintenance packages that seamlessly enhance your operational experience.

"When you invest in a FlexJet, you will get a high-quality, high-performance waterjet system that comes with a level of service you can rely on."

- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here