FL-0404

Speed / Accuracy

Ballbar Circularity …………………<0.003 in.

Acceleration ………………………….. 0.3G

Maximum Traverse Speed …….. 1,400 in/min

Ballbar Circularity ……………… <0.003 in.

Acceleration …………………….. .3G

Maximum Traverse Speed … 1,400 in/min

Standard Specifications

Material Support Slats: Steel

Abrasive Bulk Hopper: 500lb continuous fill

Electrical requirement: 3-Phase, 480 V

22″ Touch Screen HMI & Roll Around Control

Hand Pendant

CAD-CAM Express

Optional Equipment

Quality Parts, Fast

With the fastest rapids in its class, the FL-Series offers greater efficiency for less time per part. This fast yet highly accurate cutting solution offers versatility at a value.

Built to Last

Designed and constructed using tried and true technology, the FL-Series is a dependable cutting solution built to last. The all-steel two-piece construction features a helical rack and pinion for higher accuracy and increased longevity.

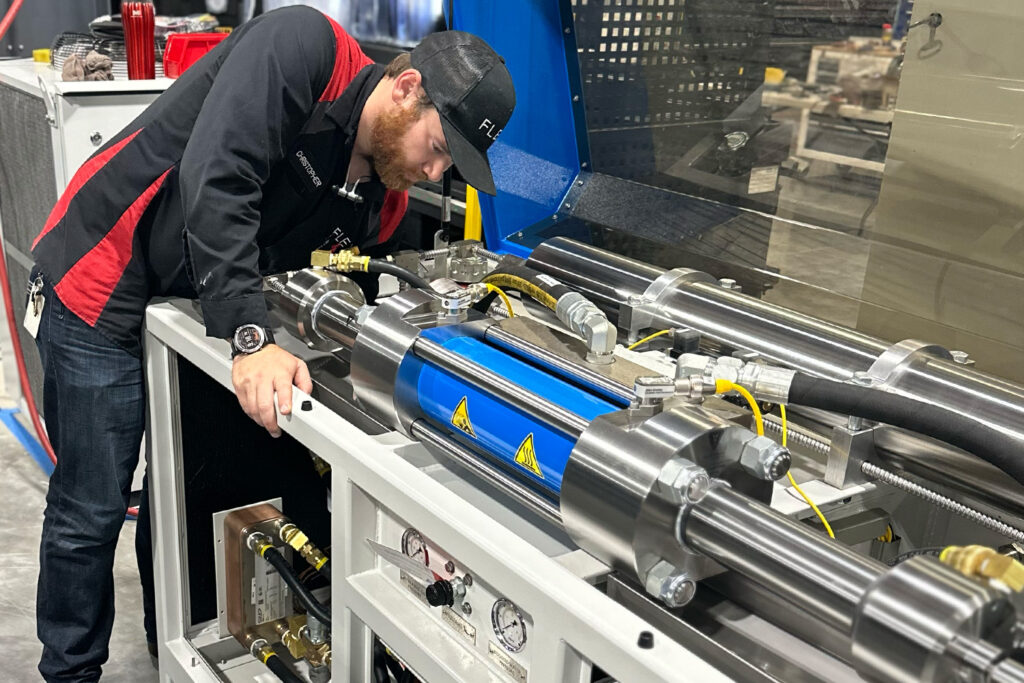

Unmatched Service

Highly experienced service technicians there when you need them. From installation and training to preventative maintenance and consumable packages, we offer a level of service you can rely on.

FL-1004

* Built to order sizes available in 5 ft increments.*

Speed / Accuracy

Ballbar Circularity …………………<0.003 in.

Acceleration ………………………….. 0.3G

Maximum Traverse Speed …….. 1,400 in/min

Ballbar Circularity ……………… <0.003 in.

Acceleration …………………….. .3G

Maximum Traverse Speed … 1,400 in/min

Standard Specifications

Material Support Slats: Steel

Abrasive Bulk Hopper: 500lb continuous fill

Electrical requirement: 3-Phase, 480 V

22″ Touch Screen HMI & Roll Around Control

Hand Pendant

CAD-CAM Express

Optional Equipment

Quality Parts, Fast

With the fastest rapids in its class, the FL-Series offers greater efficiency for less time per part. This fast yet highly accurate cutting solution offers versatility at a value.

Built to Last

Designed and constructed using tried and true technology, the FL-Series is a dependable cutting solution built to last. The all-steel two-piece construction features a helical rack and pinion for higher accuracy and increased longevity.

Unmatched Service

Highly experienced service technicians there when you need them. From installation and training to preventative maintenance and consumable packages, we offer a level of service you can rely on.

100 % MANUFACTURED IN THE USA

WATERJET SERVICE

With Flex, we don’t just provide you with a service; we’re your dedicated partners in optimizing your productivity. Our approach revolves around your needs, guided by a team of seasoned service engineers who stand ready to deliver solutions and minimize downtime quickly. We understand the importance of keeping your machinery operational, which is why our nationwide network ensures expert assistance no matter your location. With over 20 years of accumulated experience, coupled with ongoing training, our service experts excel in tackling the ever-evolving challenges of the industry. And to ensure your equipment remains at its best, we offer comprehensive maintenance packages that seamlessly enhance your operational experience.

"When you invest in a FlexJet, you will get a high-quality, high-performance waterjet system that comes with a level of service you can rely on."

- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

937-210-9541 or

Request Service Here