CNC machinery can have problems arise, and some of these problems are more common than others. When these problems occur, FlexCare+ steps in to get them resolved for you and back on track for new or current customers. These problems can include:

#1 Fixturing

CNC machinery can have problems when the workpiece that is being operated on cannot be gripped correctly by the work holding on the machine. A complex fixture can sometimes be as difficult to manufacture as the part it was supposed to hold. Besides this, it can also lead to vibrations and chatter during the process, and on occasion, an accident can happen.

#2 Wrong Tools or Settings

By not picking the right tools or selecting the proper settings, you can have problems with your machinery or the product you may be working with. When this happens, the feed rate can be critical because if it is too low, the product will remain in the path of the cutting tool for too long and leave burnt or unwanted marks on the product.

#3 Errors in Programming

A computer system controls these machines through the program that is installed. This system can cause issues in the programming and lead to product errors and mishaps. It is valuable to understand the G and M codes used in the controller and identify where these errors occur at.

#4 Inexperienced Workers and Training

A computer system controls these machines through the program that is installed. This system can cause issues in the programming and lead to product errors and mishaps. It is valuable to understand the G and M codes used in the controller and identify where these errors occur at.

#5 Machine Vibration and Chatter

Machine vibration can wear and tear on these CNC machines and the workpiece at hand. Your tools can deteriorate a lot quicker with the vibrations and will also affect the machine’s durability in the long run. They can cause problems within the spindle housing and within the machine bed itself. These problems can sometimes happen because of the wrong tool choice or supply settings.

Let FlexCare+ Take Care of These Problems

As mentioned above, CNC machines and their operation can have many common problems. With FlexCare+, you can put a stop to these common problems. Don’t have experienced workers? That’s fine; our experienced FlexCNC technicians can help you through it and give valuable information. We pride ourselves on being able to help out our customers in a timely and cost-effective matter while doing great work. If you are struggling with your FlexCNC machine or have problems arise, please contact us and let our FlexCare+ team help you with your needs.

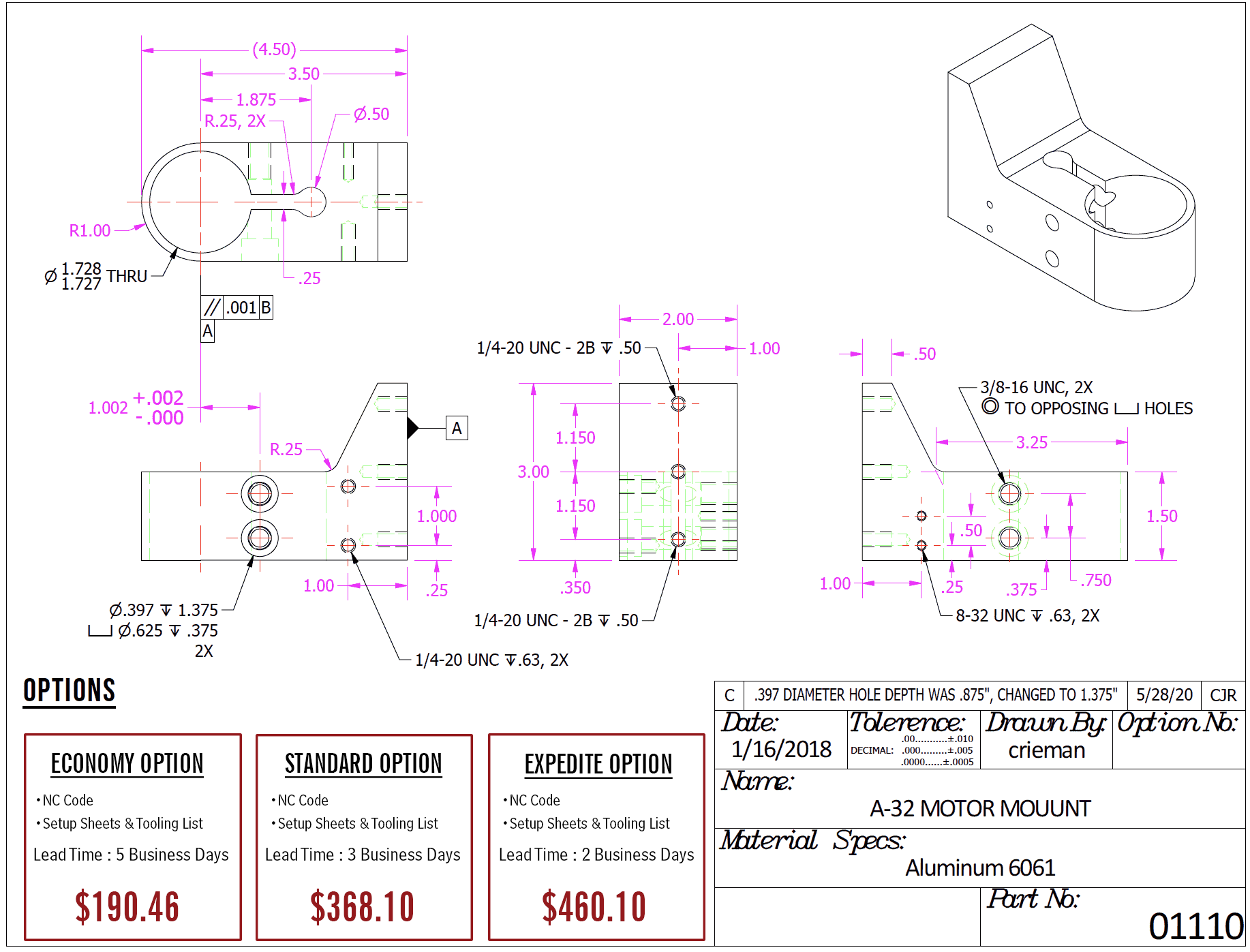

What is FlexCare+?

FlexCare+ is an on-demand programming service that is available for all FlexCNC customers. This service is available for the first year after your purchase and can also be bought by existing customers for practically no cost. FlexCare+ members can send their prints to a FlexCare+ specialist, and our specialists will provide completed programs for your FlexCNC machines. The user may choose expedited delivery (2 business days), standard (3 business days), or an economy option (5 business days). FlexCare+ is time-saving and cost-effective and can benefit you when needing to optimize your programs. Additionally, FlexCare+ specialists will consult with the customer making tooling & fixturing recommendations.