The G-20-06 is a robust and durable vertical machining center capable of machining large parts in one efficient setup. The dual drive machine moves along two oversized precision linear guideways on each axis, with a high precision helical rack and a large ball screw on the Y & Z-axis. The monobloc welded steel frame and fully equipped motion control system provide the power, stability, and durability required to deliver peak performance in a variety of machining applications

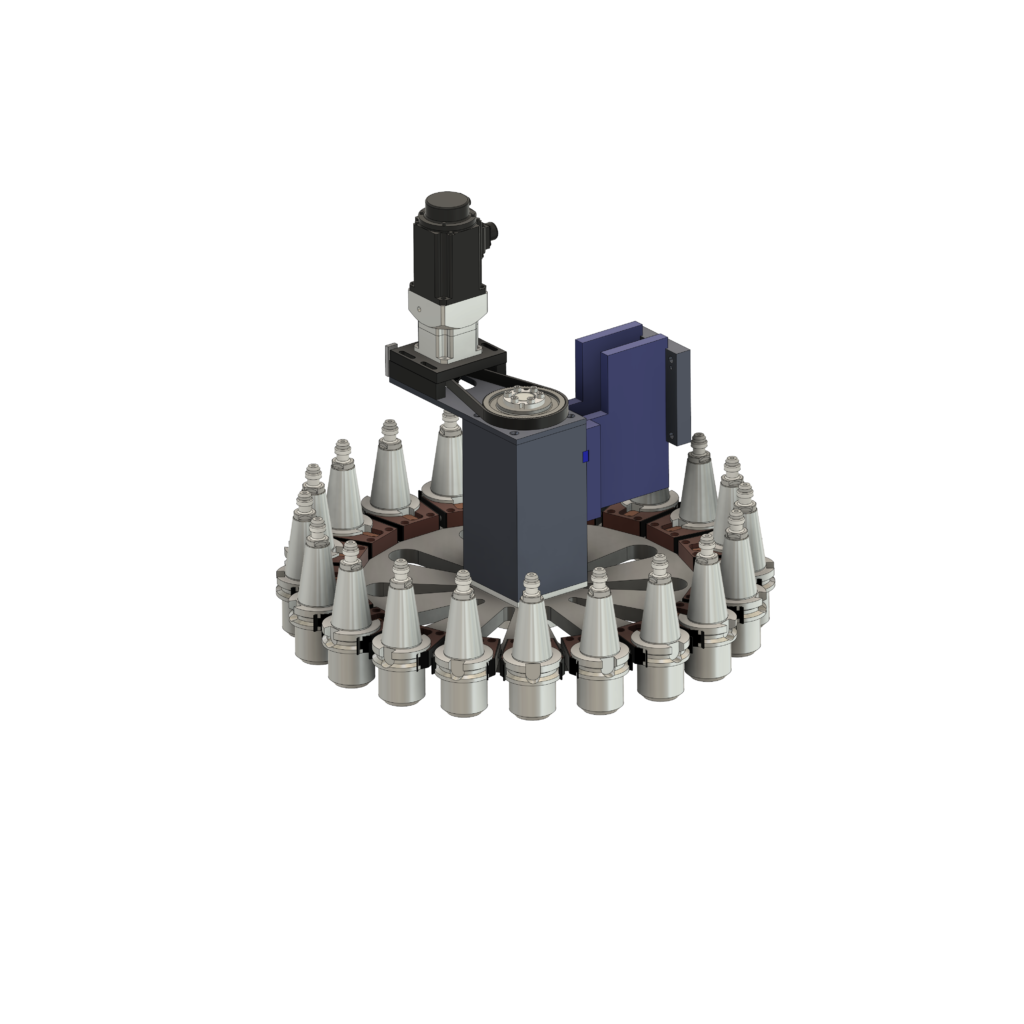

Rotary Style Automatic Tool Changer for 20 Tools

The Omron FlexCNC Control is designed and developed to allow ISO G & M-code programming for dynamic machining and is comparable to standard commercially available controllers like the Fanuc 31i. It includes the capability of integrating an optional 4th axis. An infinite read-ahead capacity allows the machine to flawlessly and smoothly machine 3D tool paths, smooth helices, and ramping tool paths. It is equipped with a:

The AMI5000 Remote Pendant is used as a Human Machine Interface (HMI). It uses EtherCAT communications technology to interface with the ANCA Motion Control System Software, allowing fast and flexible access for real-time control.

The chip auger runs the length of the machine and is mechanically driven to push the chips along the bottom channel of the bed for trouble-free chip management.

The laser scanner is one of the best safety features on the FlexCNC. It uses proximity sensors that will slow the gantry down and stop completely if your operator gets too close.

When it comes to programming a FlexCNC, no one does it better than us. Whether you already own a FlexCNC or are in the market for one, we can help you maximize your productivity.

HP |

Max RPM |

FT/LBS |

Series |

|---|---|---|---|

|

18 |

4000 |

92 |

C-20-02 / C-10-02 |

|

18 |

6000 |

61 |

C-20-02 / C-10-02 |

|

33 |

12000 |

61 |

CM-20-02 |

Auto Stand-Off – This is currently defined to be surface stand-off and not to be confused with vector stand-off in 5-axis mode. The current auto stand-off is based on a changing surface and will adjust vertically based on the angle of the “A” Axis, so there is five (5) axis taken into account during the calculations, but this is not the same as the tool vector stand-off. There is the ability to do the vector stand-off change while the machine is running manually with buttons on the screen.

Z-Reader Probe – The Z-Reader is a device for mapping the location of the surface. It can be controlled manually & programmatically. The option is NOT active while cutting & is retracted out of harm’s way. It can be triggered to verify the surface at every pierce before the cutting process starts, or it could be used to drive surface mapping of the whole part before cutting starts. It begins with initialization or zeroing of the device to the surface at the beginning of a program and then accumulates or tracks the difference from that zeroing effort.

Automatic Edge Finder – The edge finder is or can be utilized manually (Jogging Method & Screen Buttons), programmatically (M & G codes), or fully automatic routine (dedicated program). This option sets offsets & program rotation to match the orientation & location on the cutting table.

AC Unit Installed on Electrical Cabinet – The unit is mounted on the cabinet’s High Power (480v) side. It is close to the location where the drives are mounted. This option keeps the cabinet temperature stable and allows heat dissipation faster. The servo drives for all axes are the most significant contributors to heat inside the electrical cabinet.

5-Axis Renishaw Calibration – The calibration unit is a Renishaw model APCA45 with a modified spherical stylus. The device has a retractable cover and air purge to clear debris & dust during the activation process. It mounts to a swing arm controlled by a pneumatic rotary, so it is out of the way during regular operation and swings into the calibration position for calibration only.

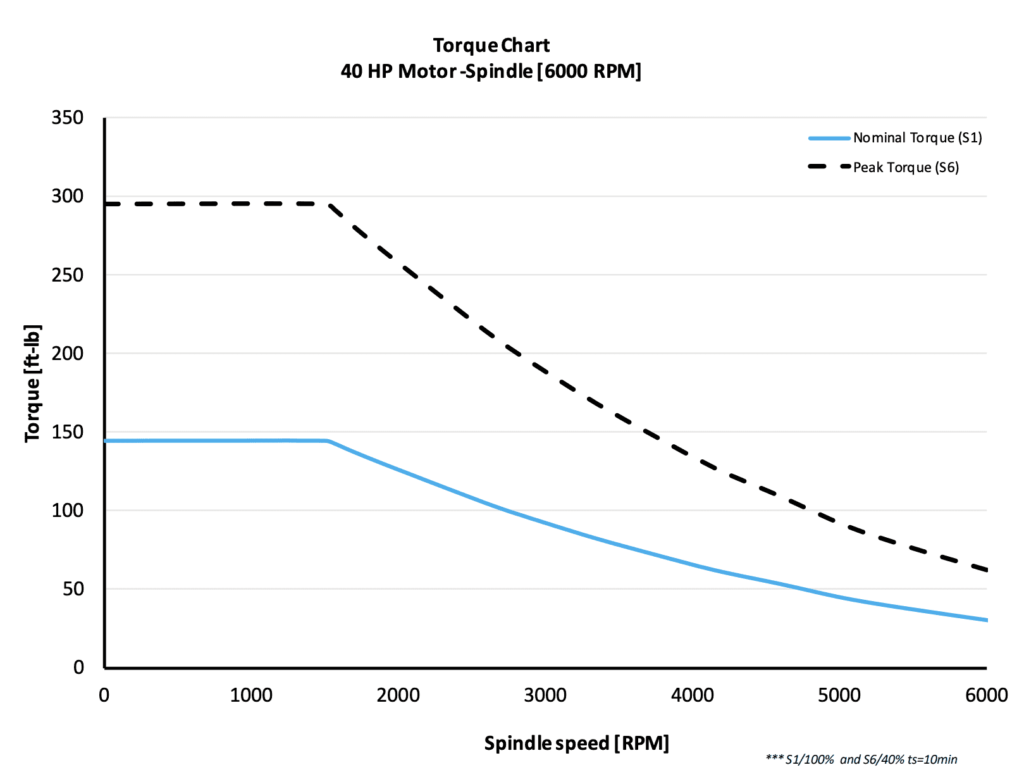

HP |

Max RPM |

FT/LBS |

Series |

|---|---|---|---|

|

18 |

4000 |

92 |

G-20-06 / G-10-06 |

|

18 |

6000 |

61 |

G-20-06 / -10-06 |

|

40 |

4000 |

217 |

GM-20-06 / G-20-06 / G-10-06 |

|

40 |

6000 |

145 |

G-20-06 / G-20-06 / G-10-06 |