The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC can perform various functions for numerous specialized projects, saving you space and money with one go-to machine. Here are some of the ways that FlexCNC can work for you:

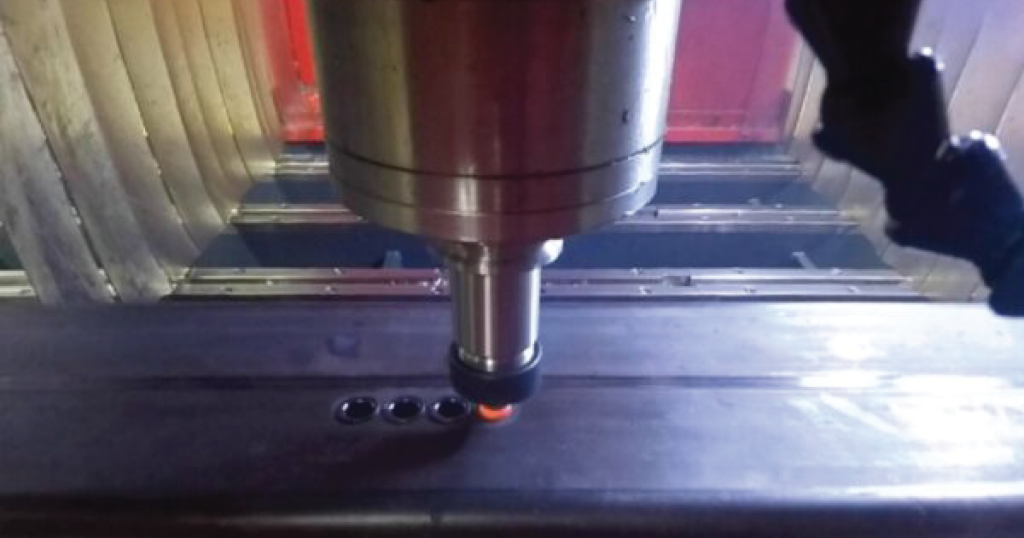

1) Thermal Drilling

Thermal drilling, also known as friction drilling or flow drilling, is a process where the metal is displaced by a conical-shaped bit moving with high rotational speed and high pressure, creating heat from friction. This allows the bit to plunge into the heat-softened metal and create a hole, collar, and bush by displacing the original material without any loss.

2) Weldments

A weldment is a unit formed by welding together an assembly of pieces. Post-weld machining is required when the tolerances for a finished weldment are tighter than those of a human-assembled component. It can also be required as a result of forming the weldments. Man-made items can be corrected with the precision of machining to meet the necessary tolerances after assembly.

3) Keyways

Keyways are an essential machining process used to create a slot in a workpiece. Long slots are cut into a component to accept a key that engages with a similar slot on a mating component so that the two do not move against each other. They are cut vertically or horizontally along the surface of a shaft, and the type of key and keyway that is milled depends on the kind of work it is intended for.

4) Right angle tooling

Angled heads are precision tools used in machining. These are custom-style holders, and they allow the cutting tool to be angled perpendicular to the workpiece, allowing for more precise operations on the horizontal faces of the part. Some versions have a fixed angle, and others are adjustable. Some may have an option for multiple cutting attachments to allow for dual output accommodating multiple work surfaces. Milling and drilling are both available options for the angled styles of tooling.

5) 4th-axis

4th-axis machining involves an additional rotary movement around the A-axis. 4th-axis CNC cutting is an affordable alternative to a tube laser. Utilizing a 4th-axis removes the human error from repositioning a part, ensuring precision and accuracy across and around the whole part. The additional axis also makes its processes more efficient.

The FlexCNC is designed for automation and endurance. It provides top-notch versatility, flexibility, and rigidity. If you want to increase efficiency in your shop, contact us today to see how a FlexCNC can improve your processes. We will happily discuss ways you can improve productivity and keep your customers returning.