This article originally appeared in Fab Shop Magazine Direct and was written by Jimmy Myers, Senior Editor.

At Strategic Thermal Labs (STL), a company that plays an important role in cooling the CPUs and GPUs found in data centers, the name of the game is precision and speed. This played a factor in the recent adoption of waterjet cutting technology, which came with hope for a boost in production. What the company got was a game changer.

When STL launched in 2014, the company specialized as an engineering consultancy firm, offering design services to the rapidly evolving data center market. The focus from the beginning was on liquid cooling technology, an area that was beginning to emerge as a critical solution for the industry. For several years, STL provided engineering design services, helping major organizations in the data center industry develop prototypes and explore cooling solutions.

That model shifted in early 2023 when STL transitioned from a design-only company into a manufacturer of products used to cool computer systems, including cold plates and heat exchangers. They moved out of a cramped location where a few machines had pushed space to the limit and into a new 60,000-sq.-ft. facility in Georgetown, Texas.

The larger footprint allowed STL to scale up their design and prototype services into production manufacturing, focusing on precision cooling solutions for chip manufacturers, hyperscalers and Tier 1 OEMs. An integral piece of machinery the company uses today for that manufacturing includes the aforementioned four-head waterjet from Flex Machine Tools.

Intuitive and easy to use, implementing the waterjet with its IGEMS CAD/CAM software and nesting capabilities not only helped Strategic Thermal Labs reduce waster, but they are also processing material faster than ever.

Cooling Data

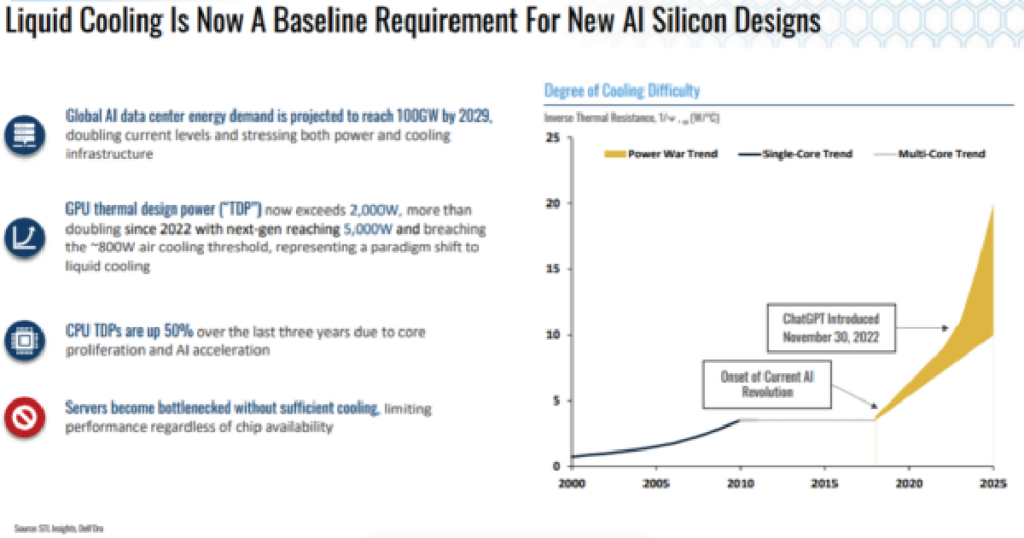

Data center cooling has historically relied on air systems. But as Tiffany Hancher, STL’s director of marketing, notes, today’s data centers need a more effective solution for cooling. AI and machine learning workloads have surged, particularly since the onset of the AI revolution and then the introduction of ChatGPT in 2022.

According to a study by STL and Dell’Oro Group, a market research organization, globally, AI data center energy demand is projected to reach 100 gigawatts by 2029, which will double the current levels and put stress on the world’s power and cooling infrastructure. One result of this will be servers that become bottlenecked without sufficient cooling.

Hancher says that air-based cooling has reached its limits. Liquid cooling is no longer optional – it is essential for keeping up with demand, and STL is poised to ease those potential bottlenecks by producing more liquid cooling units.

“It’s really important to share that this is what is needed now in this industry, and that’s why we’re here,” she says. “We’re able to ramp up production to meet demands.”

Jimmy Morse, chief operating officer at STL, says the company has taken a clear position on the best approach for moving forward: The team believes single-phase water cooling offers the best balance of performance, efficiency and total cost of ownership.

“There’s a lot of debate about single-phase versus two-phase, water versus refrigerant and even immersion cooling,” Morse says. “We’ve put our stake down with water. We believe it’s the most effective solution for businesses looking at cost and performance together.”

Waterjet for the Win

As part of producing water-based cooling units, STL needed machinery that could handle a variety of materials with precision and efficiency. One of the first places the team looked was waterjet cutting technology. Waterjet is known to cut copper, among other materials, quite well due to the cool cutting.

Copper, known for its low thermal resistance, is one of the primary materials STL uses in production. The company also works with aluminum, steel and occasional plastics, but copper remains the go-to material due to its ability to transfer heat effectively from CPUs and GPUs.

Corey O’Flaherty, senior production specialist at STL, says that before investing in waterjet technology, STL relied on bandsaws to cut stock, a process that was often inefficient, wasteful and proved limiting in terms of production flexibility. O’Flaherty, who is from Ohio where Flex is based, was familiar with the company’s products. He’d actually worked one of the company’s milling machines with a previous company. He says he knew Flex Machine Tools had developed waterjets, so he reached out to them.

STL worked with Flex to configure a waterjet that best fit the cutting requirements. Flex designs, engineers and builds custom systems in its U.S. manufacturing facility. The answer for STL was a custom FLX 1308 “FlexJet” waterjet system with four, 3-Axis cutting heads on a shared gantry with four distribution hoppers. Each head uses identical consumables, allowing the same profile to be cut multiple times in parallel.

The system has a 100 HP motor and features a large 13 ft. by 8 ft. bed capacity with a work envelope of 12 ft. by 13 ft. by 8ft. The waterjet is further equipped with IGEMS technology including CAD/CAM software, a camera for optimal positioning, a kinematic compensation tool, and perpendicular angle tool. Capable of cutting 1,800 IPM with an acceleration of .5G, the FLX 1308 also has a 4-in. water control rising level for cutting under water.

O’Flaherty says switching to waterjet changed everything.

“Moving to plate cutting gave us flexibility and efficiency,” he says. “We could nest parts, cut from plate stock and significantly reduce waste. Plus, the consistency and accuracy of cuts simplified downstream machining.”

Hancher adds that they are also profiling parts “four times faster than before. Further, with the waterjet, we can use a standard plate size across multiple products.” She says the quadrupled throughput was a decisive factor in declaring success.

“We’re cutting 3-ft.-by-4-ft. plates,” Morse says, “sometimes up to 12 ft. long, generally 0.5 in. thick or less. The gantry-style design of the Flex waterjet gave us stability and repeatability, which were also critical factors in our decision.”

For STL, the waterjet is a primary cutting tool, but it is also a means to more efficient production. For example, parts coming off the waterjet go directly to vertical machining centers for finishing, so the clean, precise cuts make the finishing process much more efficient and machining tight tolerances can be achieved.

Machine Introduction

Introducing a new machine tool can bring challenges, but STL’s experience with the Flex waterjet was smooth.

“The waterjet itself is intuitive,” Morse says. “If you’re familiar with machining, its setup and operation are straightforward. The nesting function was the only area that required some adjustment, but Flex worked closely with us to get the IGEMS CAD/CAM software integrated properly for our four-head configuration … I wanted to figure out what I didn’t know before asking questions. Flex offered support every step of the way, so we were never stuck.”

Flex’s ability to provide a tailored waterjet was crucial. As Flex’s regional manager, Sam Alvarez says, every customer’s needs are different, which is why he and his team ask plenty of questions and recommend the best machine for the jobs. They will even do test cuts.

“With STL,” Alvarez says, “we knew early on that the multi-head machine with a custom bed would meet production demands.”

Morse concurs, adding that when they were shopping for a solution, “the biggest features that stood out to us were the throughput and the four heads.”

With four heads and various customizations to the FlexJet, STL, which now has 15 different products in production on this system, has experienced faster changeovers with the waterjet, which means they can pivot without missing a beat. And when help is needed, Flex has a support team that is responsive and helpful.

When Strategic Thermal Labs began researching metal fabrication tools for production, they discovered waterjet technology would be the way to go. The best option was the four-head unit shown here.

Future Growth

Though still early in the manufacturing phase, STL has already seen clear benefits from implementing waterjet technology, as it has reduced material waste – the nesting feature in the IGEMS software helps minimize waste and get the most out of every sheet.

The team has also increased throughput. Even though the exact percentages are difficult to quantify, internal estimates suggest productivity gains are around four times greater compared to previous processes.

While the Georgetown facility has room for growth, STL’s current production goals are being met with a single waterjet system. Running multiple shifts provides the necessary capacity, and the company is focused on expanding machining capabilities alongside waterjet cutting.

“Right now,” Morse says, “the waterjet is exceeding the speed at which we can machine parts. That tells us we chose the right tool.”

For STL, the broader mission extends beyond just throughput.

“We’re proud to manufacture in the United States,” Morse says. “Raw materials come in here, we process and finish them here, and they ship directly from our facility. That’s important to us and to our customers.”

Read the article on Fab Shop Magazine here.