All FlexJet models come with a multitude of customizations, including the type of cutting head. The waterjet cutting head you choose can depend on many factors, the most important being what you are cutting and how you want it cut. This article will break down the differences between our cutting heads to help you choose the best fit for your application.

Conventional Cutting Head

The Conventional Head is a fixed abrasive IDE cutting head. The standard, vertically mounted head is ideal for conventional profile cutting. Industries that cut flat parts or other 2D projects are well-suited for this type of head.

The Conventional Head is simple to use, with a programmable Z-axis and the option to mount multiple heads on one machine for increased production.

Tilter Waterjet Cutting Head

The Tilter is an innovative head with numerous features that make waterjet cutting a breeze. Our partnership with IGEMS led to this impressive design, which added many features that all contribute to the waterjet’s superior performance.

The Tilter can tilt ±45° from one fixed focal point and requires no head rewind, requiring fewer readjustments during cutting. Taper is an inherent challenge to waterjet cutting and can significantly affect the quality and accuracy of the cut, causing parts to fall outside of tight tolerances and design specifications. The Tilter alleviates this issue by compensating for kerf taper. It maintains perfect alignment of the cutting head throughout all cutting speeds, ensuring square, taper-free cuts at higher speeds for reduced cycle times.

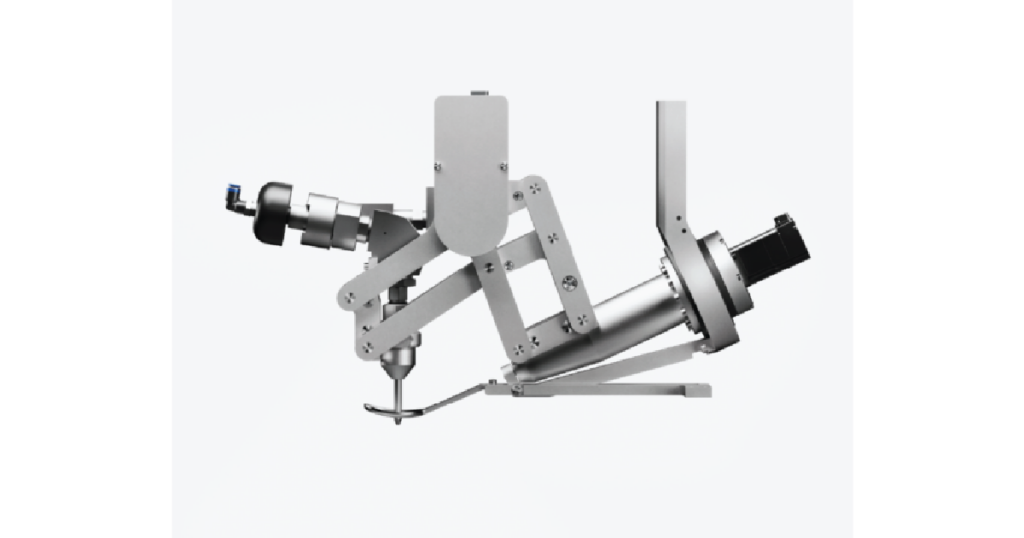

5-Axis Waterjet Cutting Head

The Flexjet 5-axis head is our most advanced head. With an infinite C-axis, it can tilt ±70°, ideal for complex 3D cuts on round or complex parts, giving you flexibility, greater reach to access difficult locations, and enhanced performance.

The 5-axis head features limitless rotation. Some OEM’s 5-axis heads are required to unwind after a full rotation, adding to programming complexity, increasing total part cycle time, and lowering overall productivity and efficiency. However, the Flexjet 5-axis head can rotate without reversing and even moves at 60 RPMs. This means the FlexJet can work without stopping, ensuring your operation stays productive.

Conclusion

Consider the FlexJet for greater flexibility and innovative engineering. From 2D cuts to 3D designs, each head promises speed, accuracy, and top-notch performance. Ready to upgrade your cutting operations? Contact us today for a free quote on a FlexJet.