A customer came to Flex looking for an ergonomic solution to help lift and maneuver a 40-pound Milwaukee Tool Electromagnetic drill press. The weight is often the biggest complaint among its users, causing discomfort and strain while using the tool. The FlexArm engineering team designed and created a custom solution to counterbalance the mag drill and remove the lifting burden.

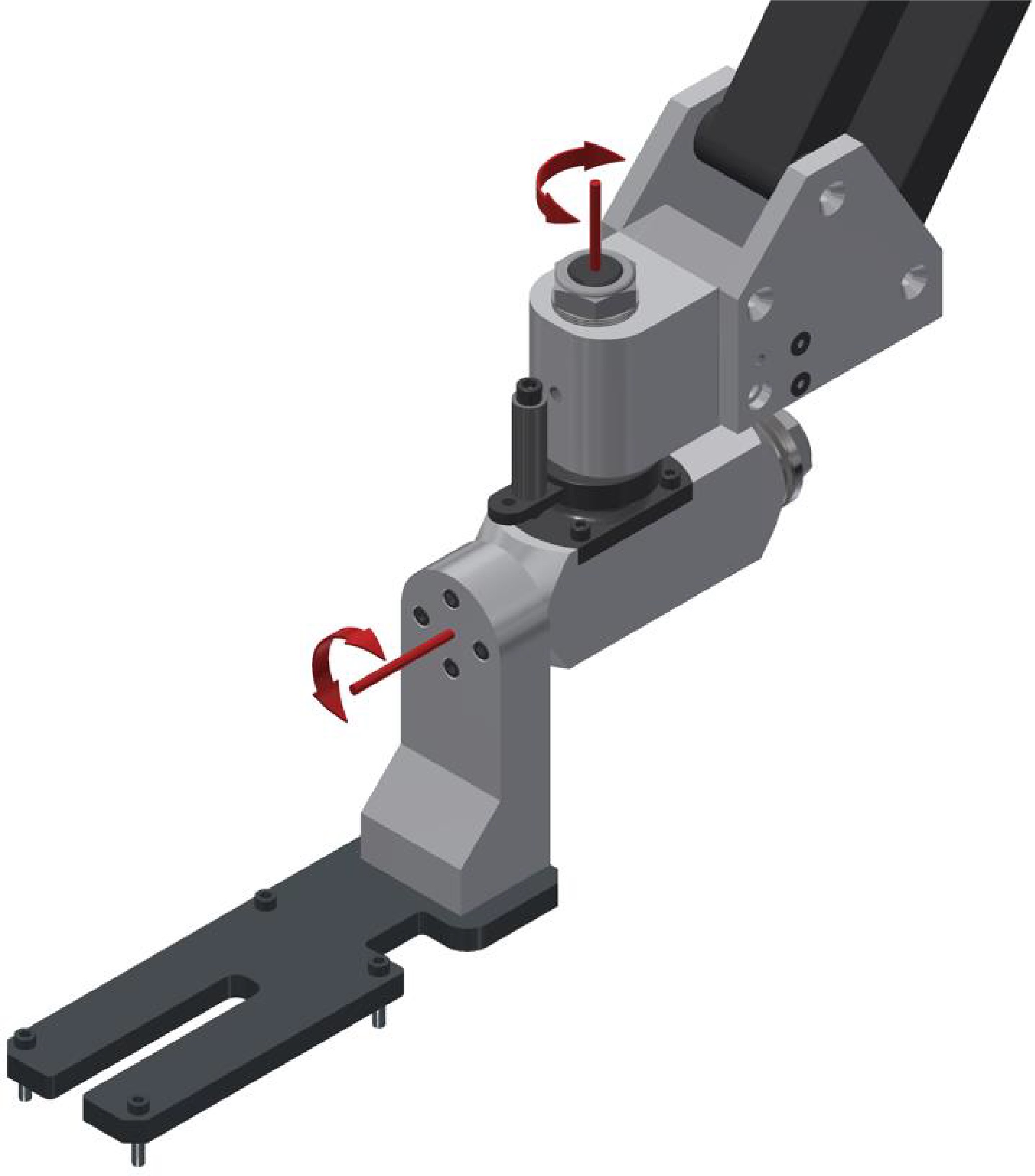

The custom tool mount is specifically made to hold the Milwaukee 4203 mag drill on the G-30 model arm with max cylinders designed to handle weights between 30-50 pounds. The mount is engineered to allow the drill to rotate 220 degrees vertically and 360 degrees horizontally, with locking detents every 90 degrees. The tool mount connects to the drill body and magnet using the existing bolt pattern on the tool, providing a secure and stable connection.

Utilizing a FlexArm to counterbalance your tool offers the advantage of safeguarding it from damage. The weight of heavy tools can cause harm if accidentally dropped or knocked over, but with a balance arm, they remain secure and readily accessible at all times.

The custom tool mount and arm solution by FlexArm eliminated the difficulties for operators working with the Milwaukee Mag Drill. This solution eliminated the difficulty of lifting the heavy tool, allowing operators to work comfortably and efficiently.

If you’re having difficulties with the weight of your tool and need a solution that makes operation easier and safer, reach out to us HERE or call us at 1-800-837-2503. Our team of engineers would be happy to discuss your needs and offer a solution.