Stainless Steel Tap Test with the FlexArm S36 Tapping Arm

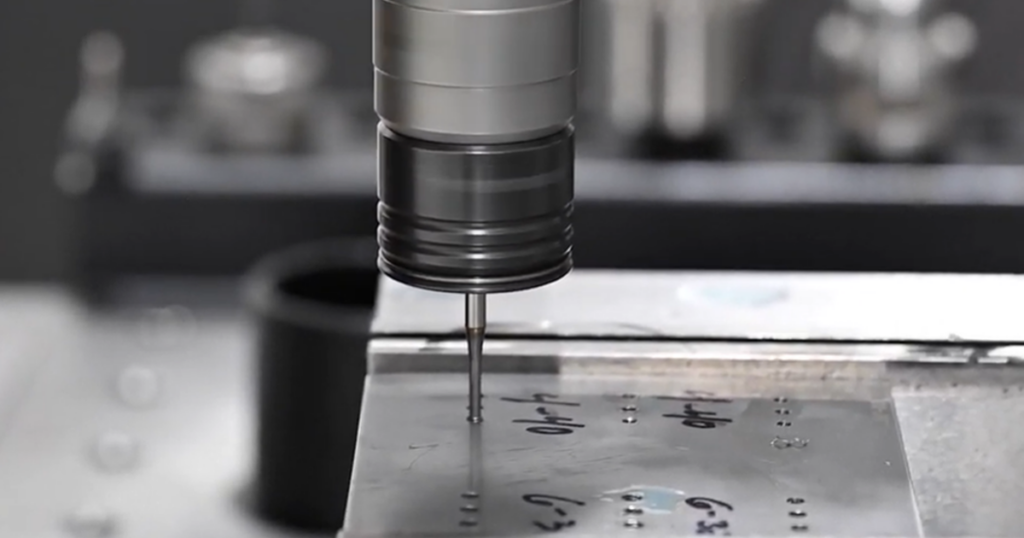

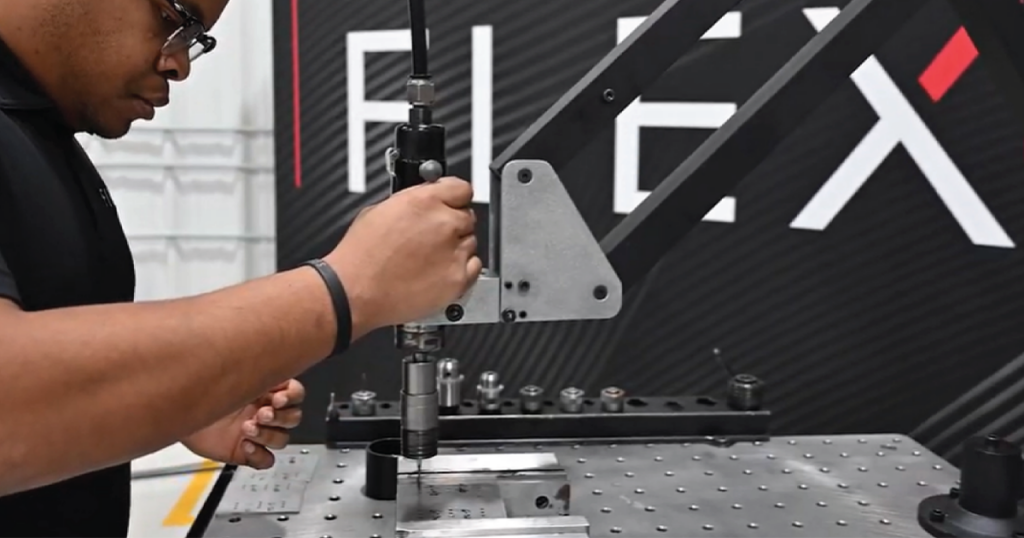

In this tap test video, Max at Flex Arm demonstrates the FlexArm S36 tapping arm tapping stainless-steel holes in parts coming directly off a laser. This type of application is common in fabrication shops that need a fast, reliable way to handle secondary tapping operations.

FlexArm S36 Tapping Arm Overview

The FlexArm S36 is designed for repetitive hole-tapping and increased production efficiency. Key features include:

- Approximately 50-inch working range for large or awkward parts

- 400 RPM motor (standard) for smooth, controlled tapping

- 25–28 ft-lbs of torque, ideal for small hole tapping in stainless steel

These specifications make the S36 a strong solution for tapping laser-cut stainless steel parts.

Easy Tapping for Laser-Cut Parts

During the demonstration, Max shows just how easy the S36 tapping arm is to use, even in stainless steel applications. The tapping process is smooth and controlled, helping reduce operator effort while maintaining consistent thread quality.

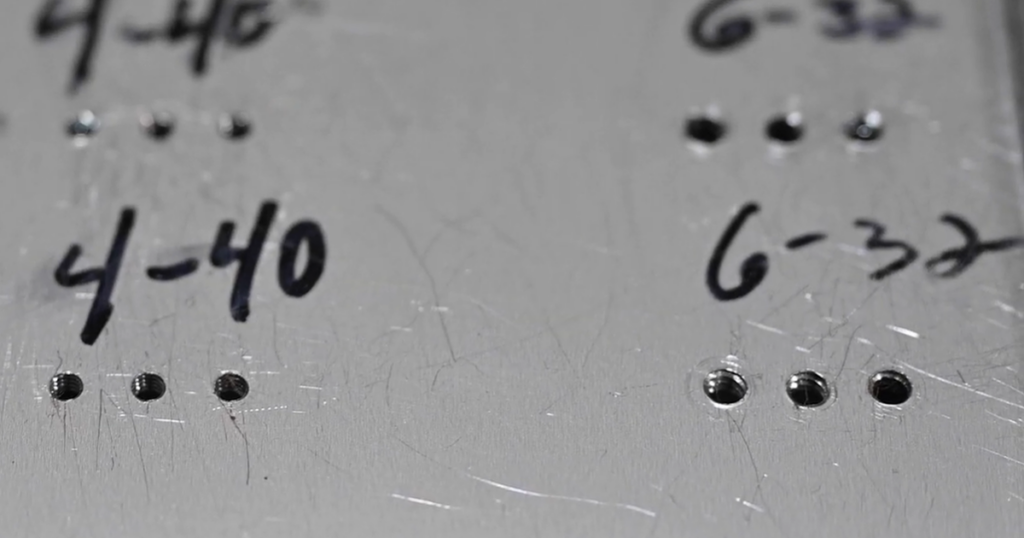

The S36 is especially well-suited for shops tapping 4-40 or 6-32 holes, including metric equivalents, where high hole counts demand speed and repeatability.

Need Help with Your Tapping Application?

If your shop regularly taps stainless steel parts after laser cutting, the FlexArm S36 tapping arm can help streamline your process.

Contact Flex Arm to discuss your application or request a tap test using your parts.