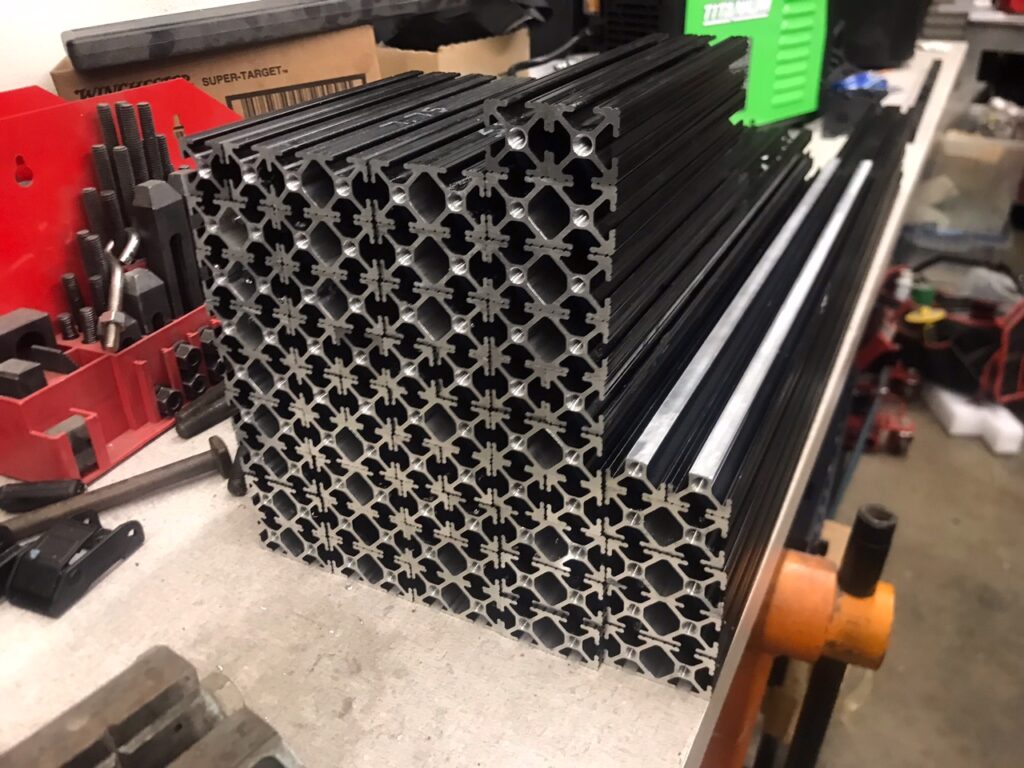

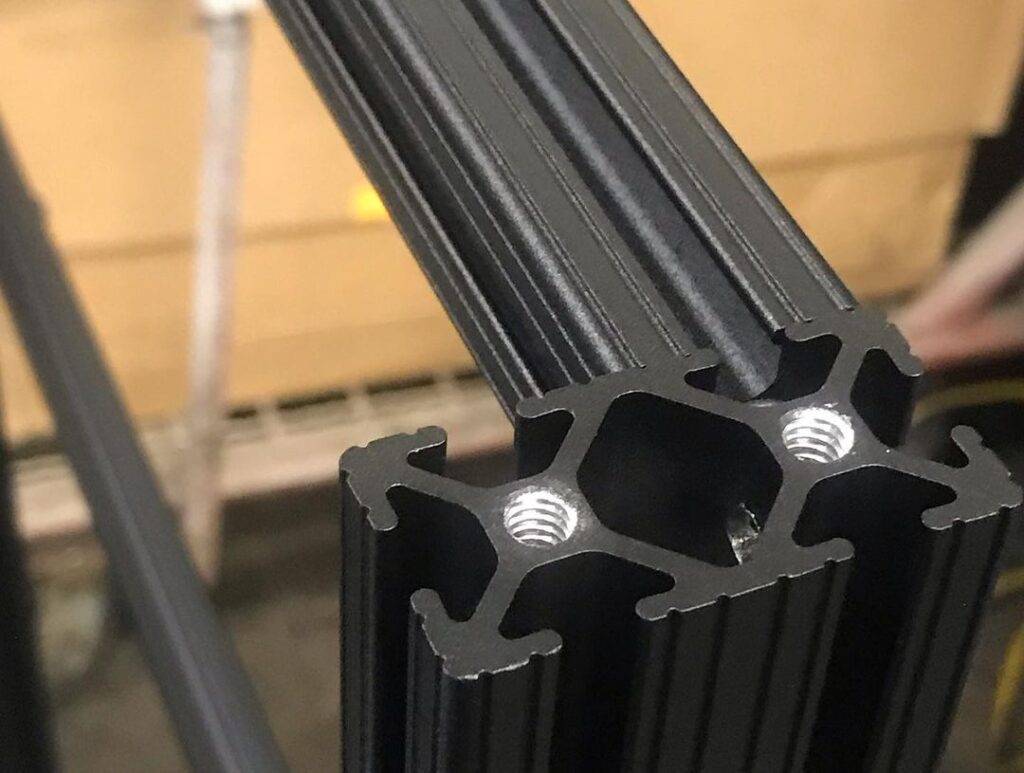

Cannibal Industries is an expert in crafting top-notch, durable equipment racks tailored to the unique demands of film and television production sets. Their specialized focus is on sound recording equipment, ensuring the utmost precision and quality. As a proud user of the FlexArm tapping arm, Cannibal Industries relies on it to tap the ends of 80/20 T-slot extruded aluminum with great ease and efficiency. Read on to learn more about who they are and what they do.

Equipment Racks

What is your company mission or brand promise?

We created our own religion we call “Uncompromising Dependability”. Whatever we manufacture must meet that standard.

What are some projects you've worked on that you are the most proud of?

The equipment fabricated in our facility has been utilized in high-profile productions such as Top Gun: Maverick, Mayans, Dr. Pimple Popper, 9-1-1: Lone Star, Star Trek: Picard, Shatner in Space, and Black-ish.

What makes your company stand out?

If a name like “Cannibal Industries” was not bold enough. The build quality of our production is internationally renowned for exceptional durability and dependability, particularly for those working in Flim/TV sound production.

How did you come to learn about FlexArm?

Abom79 on Youtube, of course!

What ultimately made you decide to purchase a FlexArm?

I’m originally from Ohio, and that is where the FlexArm’s are made.

How has the FlexArm improved your operations?

Next to our Fadal CNC machine and Solidworks, the FlexArm is hands-down one of the best investments our company has ever made.