In industrial applications, torque reaction arms play a critical role in maintaining worker safety, improving productivity, and reducing workplace injuries. An end user came to us looking for an ergonomic solution for an Atlas Copco ETV-ST101-370-FS-F Nut Runner. The FlexArm engineering team created a custom torque reaction arm to fit their needs.

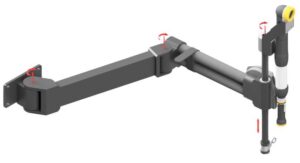

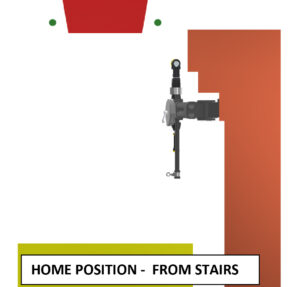

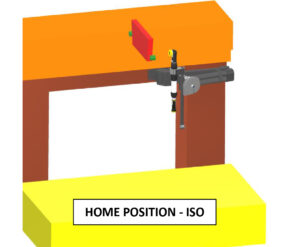

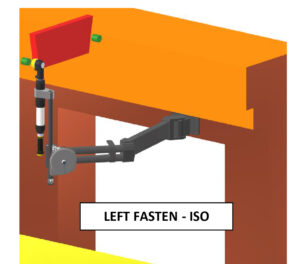

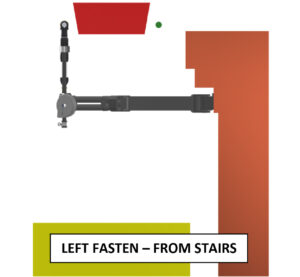

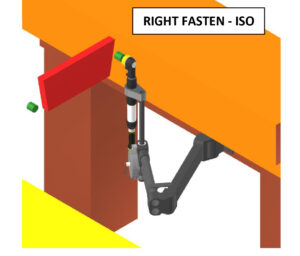

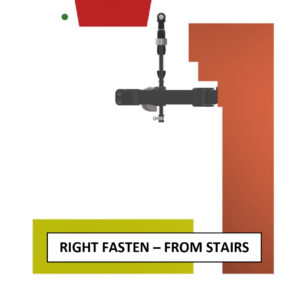

This custom torque reaction arm is designed to provide torque reaction up to 370 NM and counterbalance the 16 lb. nut runner using a cable balancer. The arm has a maximum reach of roughly 52 inches and 18 inches of vertical stroke, providing ample workspace for the operator to work comfortably and safely. The arm’s movements are indicated by the red arrows in figure 1, ensuring that the operator can position the tool precisely for side/frontal fastening.

The arm’s design ensures that the nut runner is held securely in a fixed vertical orientation, providing easy access for the operator to perform side/frontal fastening operations with precision and accuracy. The mount connects to the tool using the bolt pattern near the head of the tool, ensuring that the arm and the tool are securely connected, and the operator can work confidently.

The cable balancer used in the arm provides a counterbalancing force that reduces operator fatigue and strain on the arm, ensuring that the operator can work for extended periods without experiencing any discomfort. The cable balancer also helps prevent damage to the tool and the assembly line by preventing the tool from accidentally being dropped or hitting the work surface

The arm’s design ensures that the operator can work with precision and accuracy, minimizing the risk of errors and rework. With the custom torque reaction arm, the operator can work comfortably and safely, improving productivity and efficiency in the assembly line.

If you’re searching for a torque reaction arm that can enhance your operational ease and safety, please fill out the custom tool mount application, or call us at 1-800-837-2503. Our engineers would happily discuss your requirements and design a tailored solution to fit your needs.