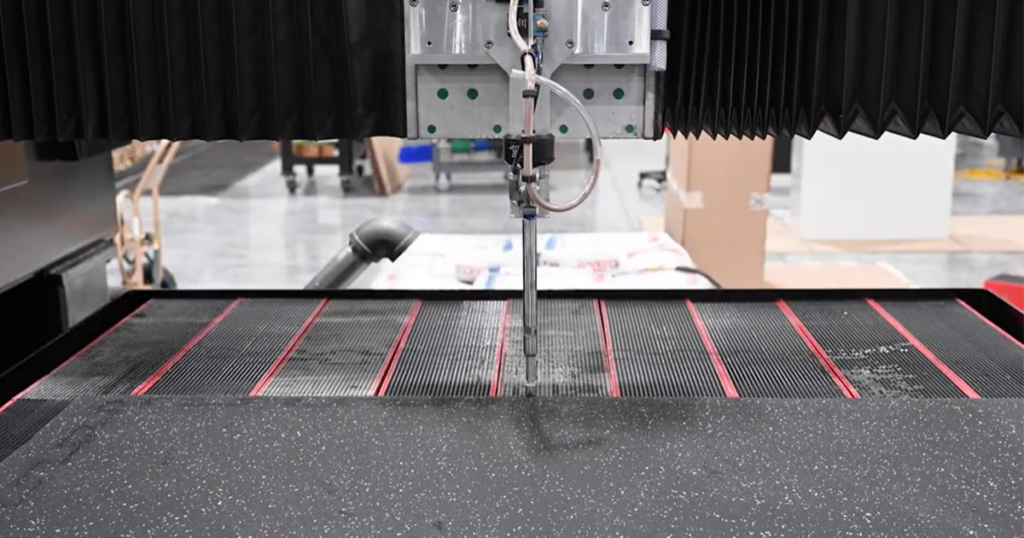

Waterjet cutting has become one of the most versatile and reliable cutting technologies in modern manufacturing. From job shops to large production facilities, waterjets are trusted for their accuracy, material flexibility, and cold-cutting process.

In this guide, we’ll answer the most frequently asked waterjet questions and explain how systems like the FlexJet waterjet help manufacturers cut more materials with confidence.

What Is Waterjet Cutting?

Waterjet cutting is a process that uses a high velocity stream of water to cut materials. When mixed with abrasive garnet, the waterjet can cut hard materials such as steel, aluminum, stone, and composites.

Because waterjet cutting does not generate heat, it avoids material distortion, hardening, or heat-affected zones, making it ideal for precision applications.

What Materials Can a Waterjet Cut?

One of the biggest advantages of waterjet cutting is its ability to cut nearly any material, including:

- Mild steel, stainless steel, and aluminum

- Titanium and other exotic alloys

- Stone, granite, marble, and tile

- Glass

- Plastics and composites

- Rubber, foam, and gasket materials

FlexJet waterjet systems are designed to handle this wide range of materials, allowing shops to take on more jobs without switching machines or processes.

How Thick Can a Waterjet Cut?

Waterjets can cut material up to 12” thick, depending on the material, pump horsepower, and cutting speed.

FlexJet systems are engineered with high-pressure pumps and rigid machine construction to maintain accuracy, even when cutting thick or dense materials.

Does Waterjet Cutting Create Heat?

No. Waterjet cutting is a cold cutting process, meaning there is no heat-affected zone (HAZ).

This makes waterjets an excellent choice for:

- Heat-sensitive materials

- Precision parts

- Parts that require welding or secondary machining

With FlexJet, parts come off the table flat and stress-free, reducing rework and scrap.

What Is Abrasive Waterjet Cutting?

Abrasive waterjet cutting adds garnet abrasive to the water stream, enabling the machine to cut hard materials like metal, stone, and glass.

FlexJet systems are optimized for efficient abrasive flow, helping reduce waste while maintaining clean, accurate cuts.

What Is Pure Waterjet Cutting?

Pure waterjet cutting uses water only, no abrasive, and is ideal for soft materials such as:

- Rubber

- Foam

- Gaskets

- Plastics

- Textiles

Many FlexJet users run both abrasive and pure waterjet applications, maximizing machine utilization across multiple job types.

How Does Waterjet Compare to

Laser Cutting?

Waterjet cutting offers several advantages over laser cutting:

- No heat distortion or hardening

- Cuts thick materials with ease

- Cuts reflective and exotic metals

- One machine for many materials

While lasers may be faster on thin sheet metal, waterjets like FlexJet excel in versatility and material range.

How Does Waterjet Compare to

Plasma Cutting?

Compared to plasma cutting, waterjets provide:

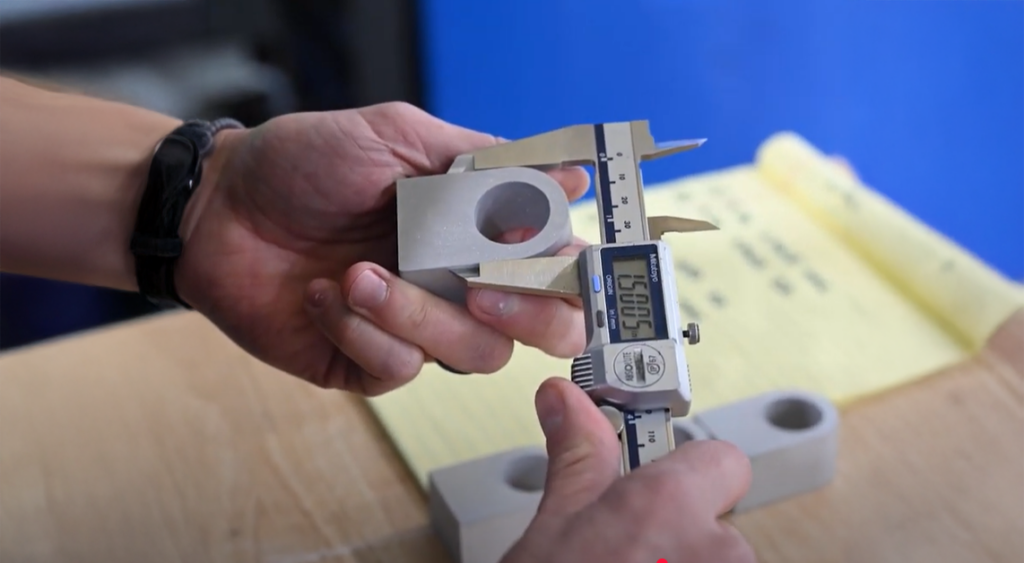

- Tighter tolerances

- Cleaner edges

- No heat-affected zone

Plasma cutting is often faster for rough cuts, but waterjet cutting is preferred when precision and edge quality matter.

Does Waterjet Cutting Require

Post-Processing?

In many cases, no. Waterjet-cut parts typically have smooth edges and minimal burrs, reducing or eliminating the need for secondary operations such as grinding or deburring.

FlexJet users often report faster overall job completion thanks to reduced finishing time.

How Much Water Does a Waterjet Use?

Despite the name, waterjets are efficient. Most systems use approximately 0.5 – 1 gallons per minute.

FlexJet systems are designed with efficiency in mind, helping control operating costs without sacrificing performance.

Is Waterjet Cutting Environmentally

Friendly?

Waterjet cutting produces:

- No hazardous fumes

- No thermal emissions

- Minimal waste

The garnet abrasive used in abrasive waterjet cutting is an inert, natural material that can be disposed of with common waste products.

Who Uses Waterjet Cutting?

Waterjets are widely used across industries such as:

- Aerospace

- Automotive

- Metal fabrication

- Job shops

- Architectural and stone

- Defense and manufacturing

FlexJet waterjets are built to serve both small shops and high-mix production environments, making them a reliable solution across industries.

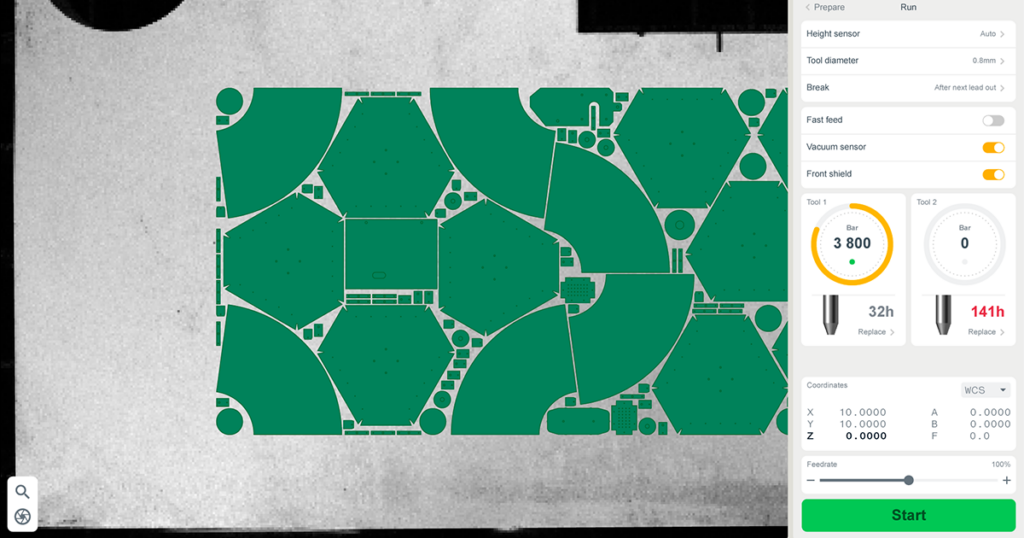

Is a Waterjet Easy to Operate?

Modern waterjets feature intuitive CNC controls, CAD/CAM integration, and automation features that simplify operation.

FlexJet systems are designed with the operator in mind, reducing training time and helping shops get up and running quickly. In addition to intuitive CNC controls, FlexJet systems include a one-time training at no cost, helping operators get up to speed quickly and reduce downtime.

Why Choose a FlexJet Waterjet?

A FlexJet waterjet offers:

- Precision cutting without heat distortion

- The ability to cut nearly any material

- A versatile platform for prototypes and production

- Free training for the life of the machine at FLEX headquarters.

- Reliable performance backed by Flex support

Whether you’re expanding capabilities or replacing an older system, FlexJet delivers the accuracy and versatility today’s manufacturers need.

Ready to Learn More About FlexJet?

If you’re considering adding waterjet cutting to your shop, or upgrading your current system, FlexJet waterjets offer a powerful, flexible solution.

Request a quote or talk with our applications team to see how FlexJet fits your workflow.