Flex Machine Tools is excited to launch a new product that will revolutionize your workshop: the Flexible Tapping Center (FTC). This specialized machine is equipped with superior precision, innovation, and performance to produce quality products for your business.

Typically, lasers are used for drilling operations, but using lasers to drill can be an imprecise practice; the part must be lined up with excessive accuracy, possibly resulting in operator error. Then, after drilling, the part must be transported from one machine to another, which is inconvenient and wastes time.

The solution? The Flexible Tapping Center.

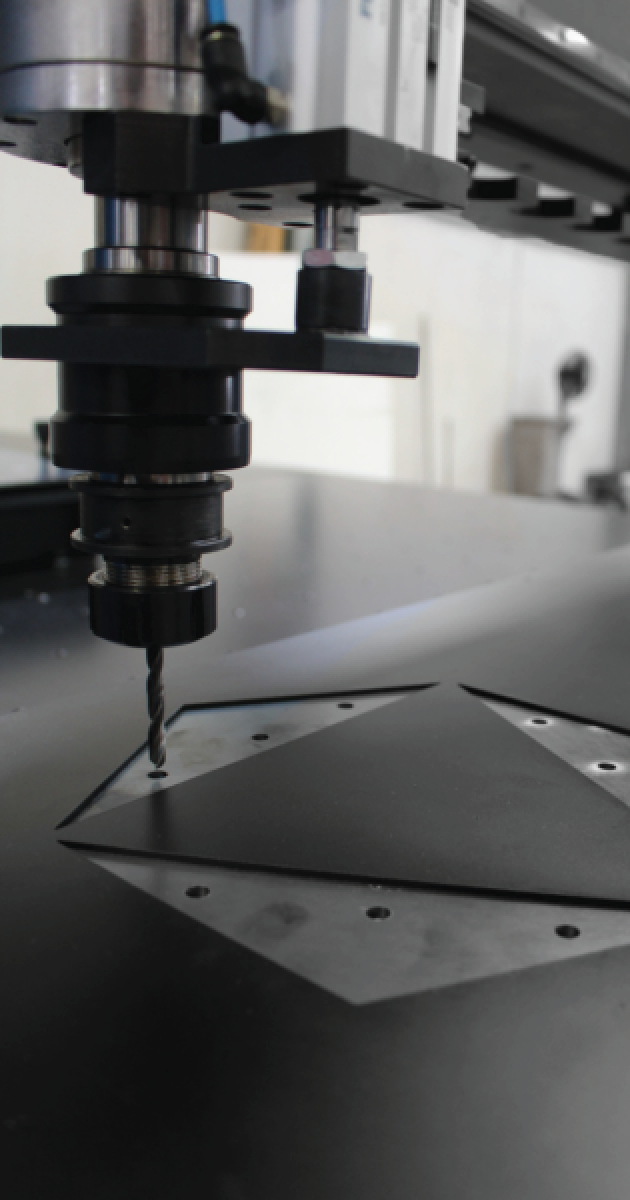

The FTC is an innovative machine designed to streamline your metalworking process. Featuring a 3-axis (X, Y, Z) moving head, these machines excel in drilling, tapping, and countersinking sheet metal sourced from a laser, waterjet, or plasma table. All in one place, the FTC will simplify your operations.

The FTC utilizes a grid table with precision linear lines to easily align parts with the open access of a welding table, making loading and unloading parts simple and quick. It boasts an automatic tool changer for eight tools and an oil-spraying system to keep the tools lubricated and maintained, minimizing downtime.

Flexible Tapping Centers incorporate a spindle guided on hardened precision linear guides. A helical rack and pinion drive the X-axis, while the Y and Z-axes utilize self-lubricating ball screws. This design ensures consistent and reliable operation. This enables the tapping process to be automated in your own workshop, allowing for high-volume production without the need for outsourcing.

In addition to the superior design and performance, you can effortlessly control tasks through our intuitive PC controller and CNC software, enabling the seamless import of 2D and 3D files for automatic conversion into machine-ready G and M Codes, streamlining your workflow.

The key feature of the Flexible Tapping Center is our innovative floating head technology, which can accommodate deviations in workpiece position up to 1mm, ensuring accuracy and efficiency. The floating head will provide your operator with quick and dependable performance. Combined with the open

table, grid precision, and our easy-to-use PC controller, tapping and drilling have never been easier.

The FTC will transform your workshop with efficiency, exactness, and reliability. If you are ready for the future of tapping operations, contact us to get a quote on yours today.