All-Steel’s Experience With The FlexCNC

Addition of CNC Machining Center Results in Strategic Shift for Fab Shop This article originally appeared in Fabricating and Metalworking Magazine and was written by

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

Addition of CNC Machining Center Results in Strategic Shift for Fab Shop This article originally appeared in Fabricating and Metalworking Magazine and was written by

For nearly a century, TE-CO Workholding has been a trusted name in the machining industry. What started in the 1920s as a small line of

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make

Maintaining tight tolerances is critical for delivering quality parts, reducing scrap, and avoiding costly rework. Even the best machining centers can struggle to hold tolerances

In manufacturing, productivity and efficiency are core concepts often misconstrued or used synonymously despite their importance to improving company throughput. Knowing the differences and intricacies

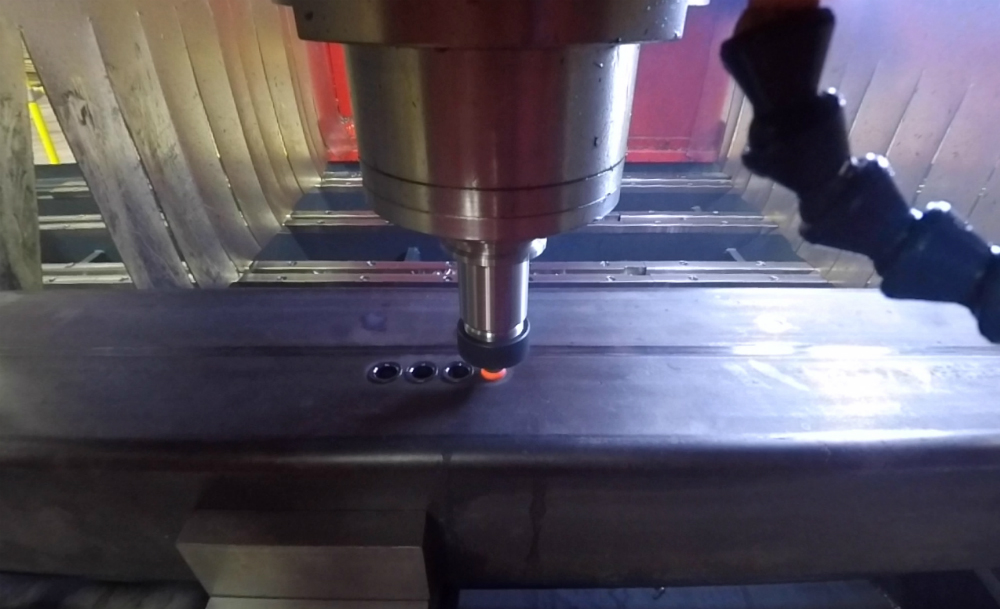

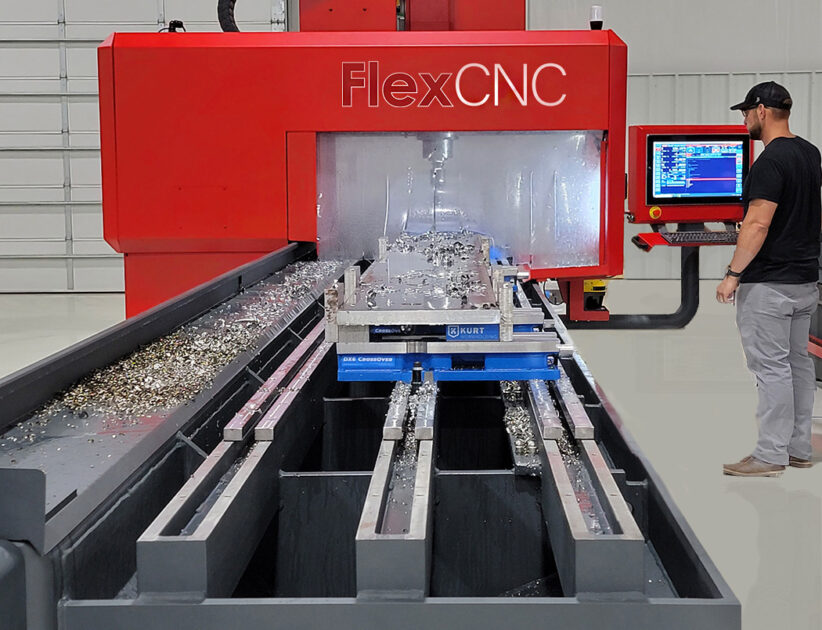

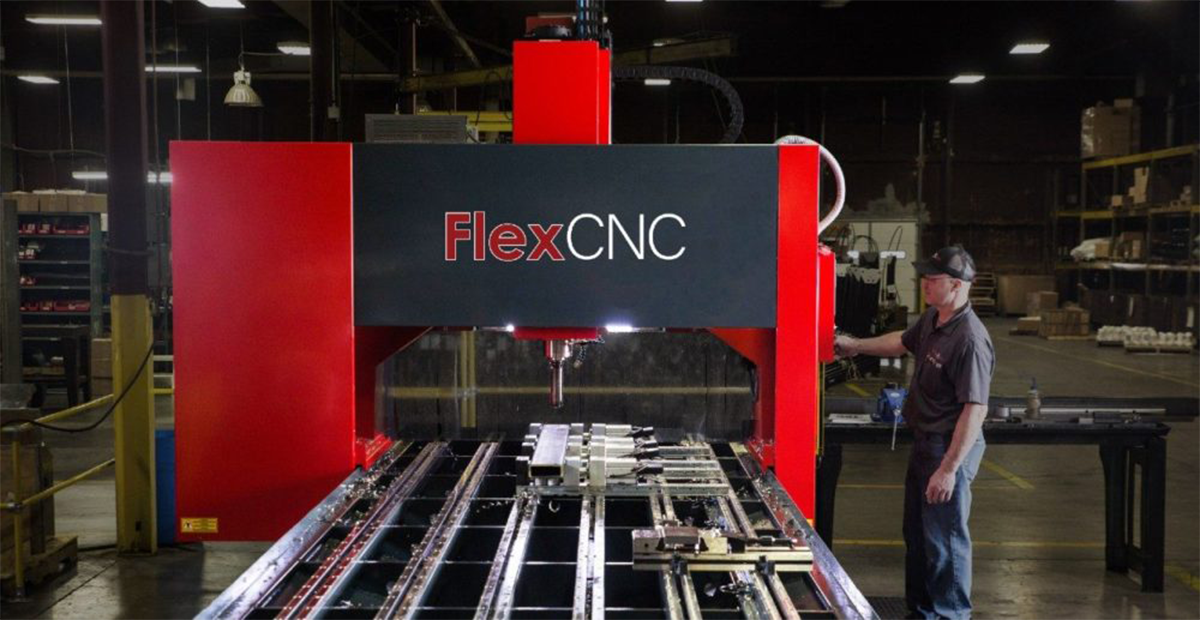

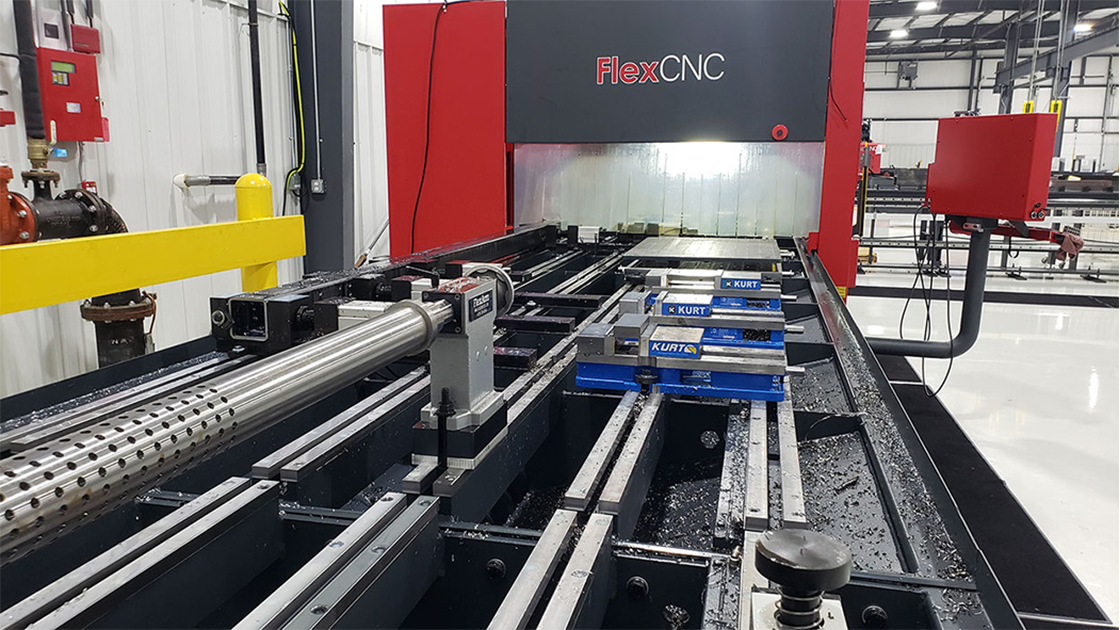

The FlexCNC is a highly automated functional machine that employs a vertical spindle and worktable orientation, allowing operations on a horizontal machining bed. The FlexCNC

If you’re a fabricator new to CNC technology, you may be wondering where to start when purchasing the right machinery for your needs. Two popular

“We use the FlexCNC for two very specific uses, one of which we had an old machine for and another that we use to do by hand.

“As a manufacturer of architectural railing systems and components, R&B Wagner, Inc. is always looking for the best way to fixture and machine long lengths

CNC machinery can have problems arise, and some of these problems are more common than others. When these problems occur, FlexCare+ steps in to get them resolved

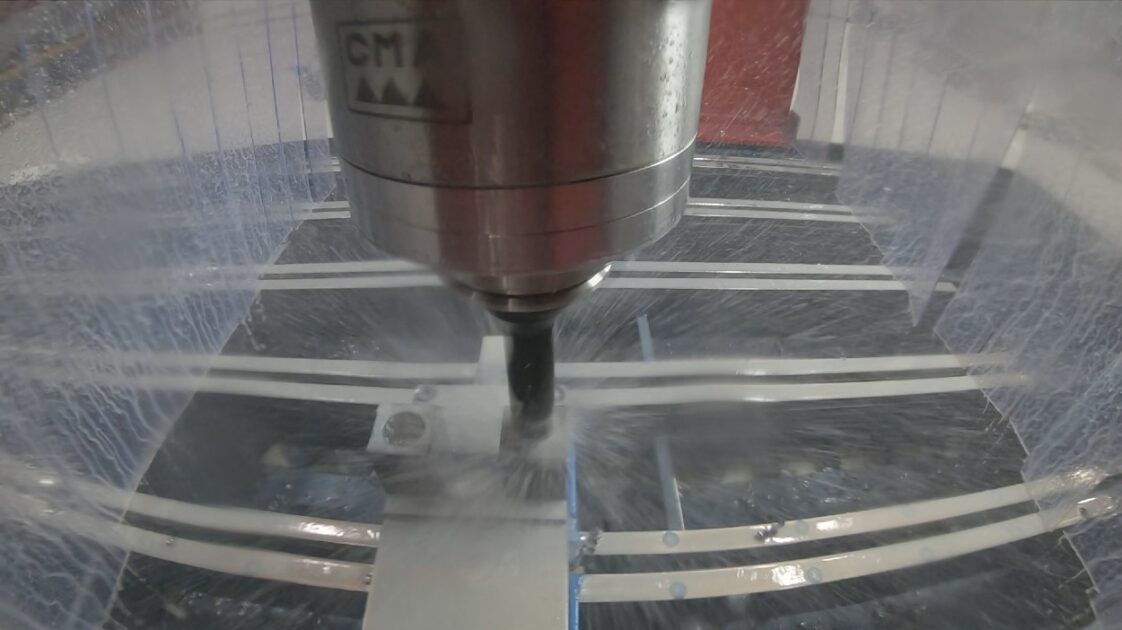

Eliminating Spindle Downtime Imagine being able to machine a bunch of different parts in one machining center without ever stopping the spindle. I know what

MACHINING CENTERS FOR FABRICATORS CNC Machining Centers are the shop workhorse that can handle some of the most challenging parts faster. Fab shops with CNC

WATCH FULL CUSTOMER STORY BELOW In the fabrication industry, staying ahead of your competitors is always crucial. With continued technological advancements, businesses need a well-rounded

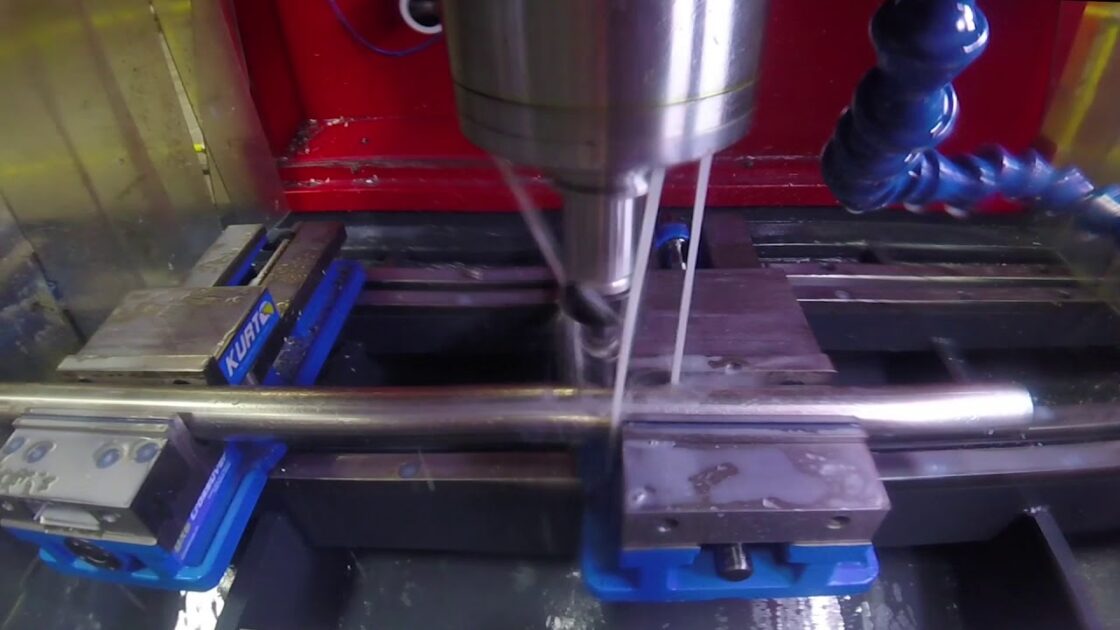

Watch the video of this time study at the bottom of the page Using a CNC Machining Center to drill is safer, faster, and more

Throughput is the number one metric for assessing the quality of a production line, and increasing throughput on a CNC means increased profitability. Flex Machine

Learning the Basics of CNC Machining CNC machining can be intimidating. Especially for people who’ve been doing manual machining for years. Understanding the G-code and

Tube lasers are incredible pieces of machinery. They’re fast, precise, and can handle a wide range of materials, including round, square or rectangular tubes, flat

Fabricators looking for a way to increase efficiency and speed up operations can achieve this with the FlexCNC. The long bed allows for the machining

Shops are always on the lookout for ways to continually improve the way they operate. Decreasing cycle times and scrap rates can help save costs

The machines you use to run your business must be kept in good working condition. Failure to do so could end up costing you in

The FlexCNC is a vertical machining center offered by Flex Machine Tools. Below are five of the many features that set this machine apart from

Processing Long Pipe & Tube with FlexCNC The old saying “Time is money and money is time” has special truth at a machining facility. Plant

WHAT MAKES FLEXCNC DIFFERENT FROM OTHER VERTICAL MACHINING CENTERS The FlexCNC can do more than other standard Vertical Machining Centers. This machining center sets itself apart with

The skills gap and labor shortage have been a hot topic in manufacturing in recent years. The challenge of being unable to find skilled workers

WATCH FULL CUSTOMER STORY BELOW Staying competitive in the ever-changing manufacturing landscape requires continual investments in new technology. Businesses are often looking for solutions that

What is Pendulum Mode? Pendulum Mode is a feature on the FlexCNC that eliminates spindle downtime increasing your overall efficiency. Some of you may know that the