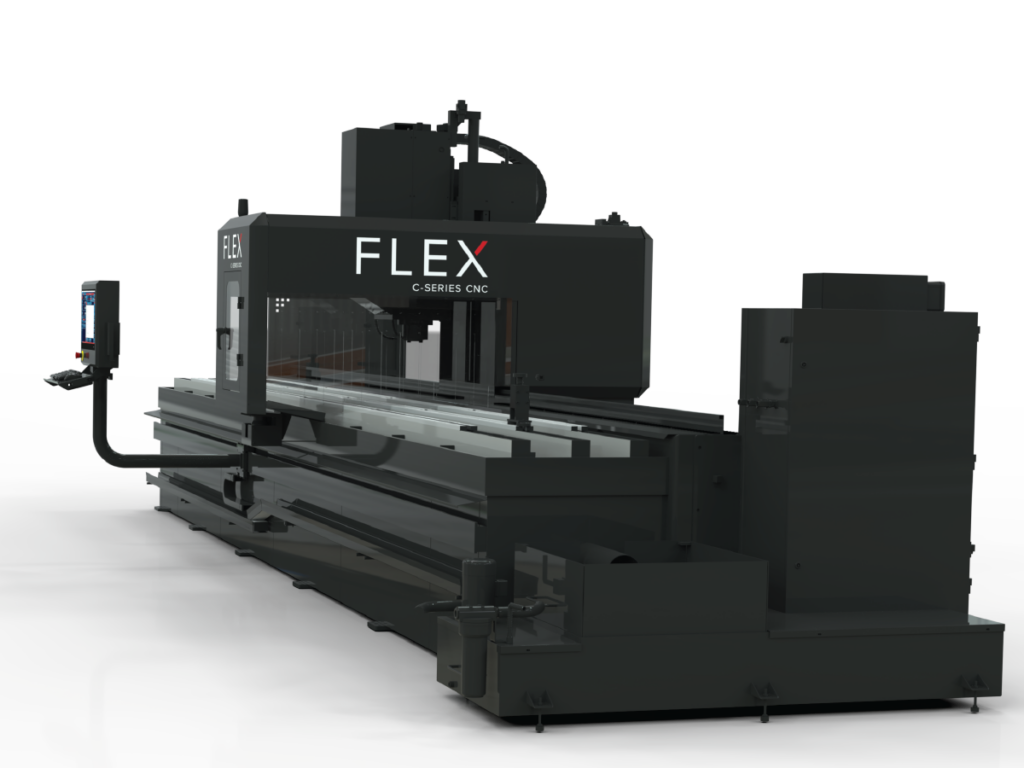

- Machining Center

FlexCNC: An Affordable Alternative to Tube Lasers

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

- WaterJet

IGEMS Software Training: 2D Basics for FlexJet Waterjets

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

- Beam Line

What is a Beam Line?

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

- FlexArm

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

- Stores

FLEXSWAG

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag

- Machining Center

FlexCNC: An Affordable Alternative to Tube Lasers

Tube lasers are powerful and efficient machines known for precise cutting of tubes and various long materials. However, their high price and specialization often make them impractical for shops with lower volumes or diverse processing needs. If you’re exploring affordable alternatives to tube lasers, the FlexCNC (long-bed vertical machining center) stands out as a versatile, cost-effective solution.

- WaterJet

IGEMS Software Training: 2D Basics for FlexJet Waterjets

Jason covers the 2D basics of IGEMS software, walking you through the essential steps to program and export a CNC file for your FlexJet Waterjet.

- Beam Line

What is a Beam Line?

Beam drill lines accurately drill holes in a variety of steel profiles at different lengths with CNC controlled programming.

- FlexArm

FlexArm includes tapping arms, assembly arms, and ergonomic tools designed to improve productivity, reduce worker fatigue, and provide custom solutions for a variety of applications.

- Stores

FLEXSWAG

If you like our Flex Swag. We now have a live store where you can purchase our FlexSwag