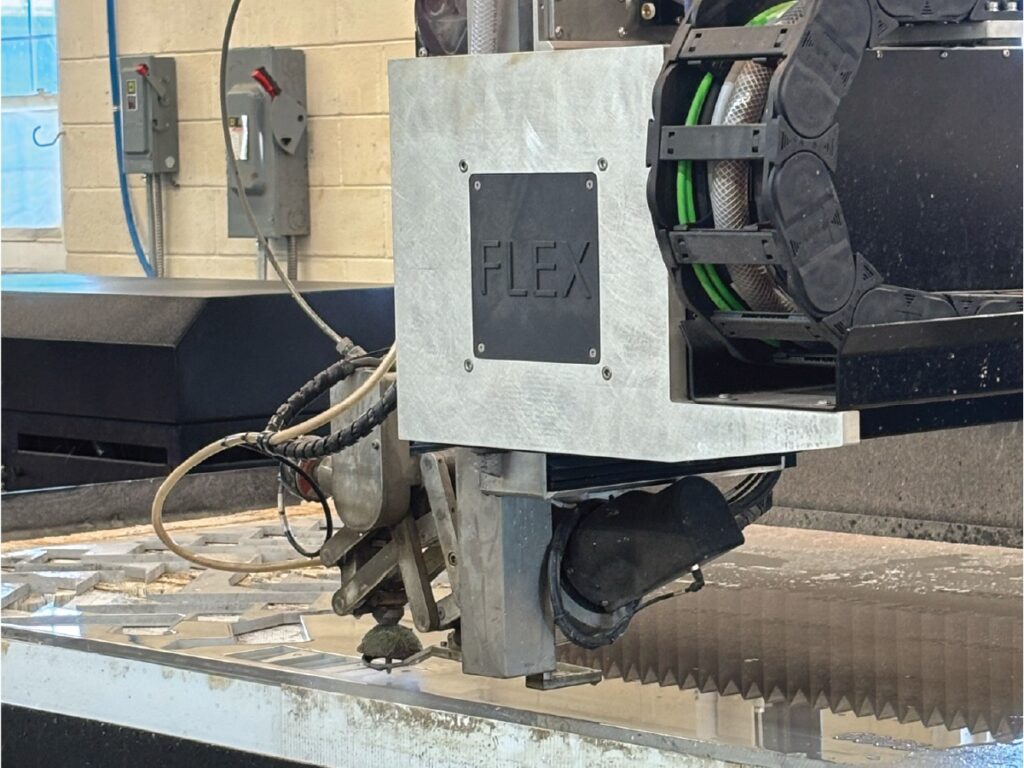

How C.A. Weld & Fab Used the FlexJet to Expand, Stand Out, and Secure Bigger Jobs

In the small town of Greencamp, Ohio, home to just around 800 people, big results come from the modest fabrication shop, C.A. Weld & Fab. Owned and operated by Chris Abbott, it has steadily built a reputation for quality, precision, and hard work. Like many small business owners, Abbott faced tough choices as he looked to grow and take on more complex projects. His decision to invest in a FlexJet 5-axis waterjet became a key turning point, opening the door to new types of work, helping him stand out in the area, and giving him the capabilities of a much larger operation without sacrificing his small-shop roots.

“Some of my projects take days, but the Flexjet just runs in the background. It’s freed me up to bid on more work and take on more clients.” – Chris Abbott, CA Weld & Fab Owner

From Cars to Custom Fabrication: Abbott’s Journey

Abbott’s path to running a successful fabrication business started with cars. What began as an automotive repair shop slowly evolved into something more. “I always had a passion for metalwork and fabrication,” he says. “I’d do it on the side a little bit, but I always wanted to go further with it.” In 2022, he took a leap of faith and launched C.A. Weld & Fab, transitioning from solely working on engines to building roll-off dumpsters, grapples, and custom smokers. He became 3G structurally certified along the way, offering millwright services and equipment repairs. While he builds heavy-duty components every day, he also serves as the Townee Trustee of Greencamp, showing that community and craftsmanship go hand in hand.

The Limitations of a Plasma Table

Like many shops starting out, Abbott’s first equipment included a CNC plasma table from Lincoln, a press brake, and several welders. The setup worked well at first, but it didn’t take long for its limitations to show. “The plasma table was fine for basic work, but it just wouldn’t do the bigger stuff we wanted to get into,” he explains. Worse yet, the table eventually developed a leak, costing valuable time and threatening customer deadlines. If Abbott wanted to compete for more advanced jobs, he needed a machine that could do more and do it reliably.

Finding the Right Fit: Choosing the FlexJet

Knowing he wanted to take the next step, Abbott researched 5-axis waterjet solutions and found FlexJet online. The fact that they were local was a bonus—he liked the idea of working with a team he could easily reach. “I wanted someone who was close to me, someone I could talk to directly,” he says. But it was more than just location that sealed the deal. After several conversations with the sales rep, he felt confident that FlexJet was the right choice. “They answered my questions and gave me the info I needed to make the call.” Once the paperwork was signed, everything came together quickly. “It all just fell into place.”

FlexJet in Action

Since adding the FlexJet to his shop, Abbott has already begun seeing a shift in what’s possible. As the only shop in the area with a 5-axis waterjet, he’s positioned to take on more complex, high-precision jobs that weren’t feasible before. “I just let it run,” he says. “While it’s cutting, I can move on to something else.” That kind of hands-off efficiency is expected to save time and boost productivity as more projects come. The FlexJet is also opening the door to different types of work and attracting customers looking for capabilities most local shops don’t offer. “It’s really helping me stand out among my competitors,” he says.

What’s Next for C.A. Weld & Fab

With the FlexJet now a key part of his setup, Abbott continues to grow his shop and take on more advanced work. While he still fabricates heavy-duty equipment like grapples and roll-off dumpsters, the waterjet allows him to cut more precisely and take on more technical projects. Being in a small town hasn’t slowed him down. “The auto repair shop got me to where I wanted to be,” he says. “Now I get to focus on the kind of work I’ve always wanted to do.” Whether it’s a quick custom job or a full-scale fabrication project, C.A. Weld & Fab shows what’s possible when the right tools meet real ambition.

For Abbott, the FlexJet marks the start of a new chapter, one that aligns with his long-term vision for the shop. It’s an investment in capability, giving him the tools to pursue more technical work and meet a broader range of customer needs. While it’s early in the process, the machine has already started to shape how he approaches each project, setting the stage for what’s ahead.

If you are looking for a more efficient cutting solution and want to automate your workflow with a FlexJet, contact us today. We would be happy to discuss your needs and show you how the FlexJet can help you increase output and take on more profitable work.