Unleash Your Shop's

Potential with FlexCNC

Maximize efficiency, precision, and safety for large and small parts with our innovative machining centers.

REQUEST A QUOTE Today

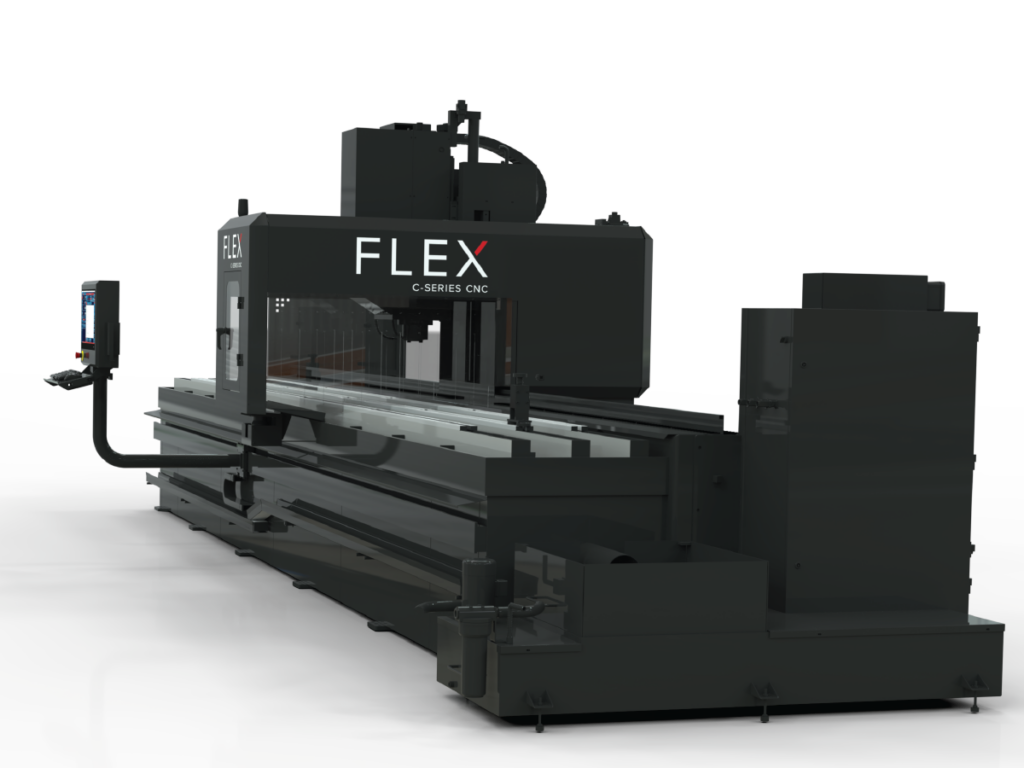

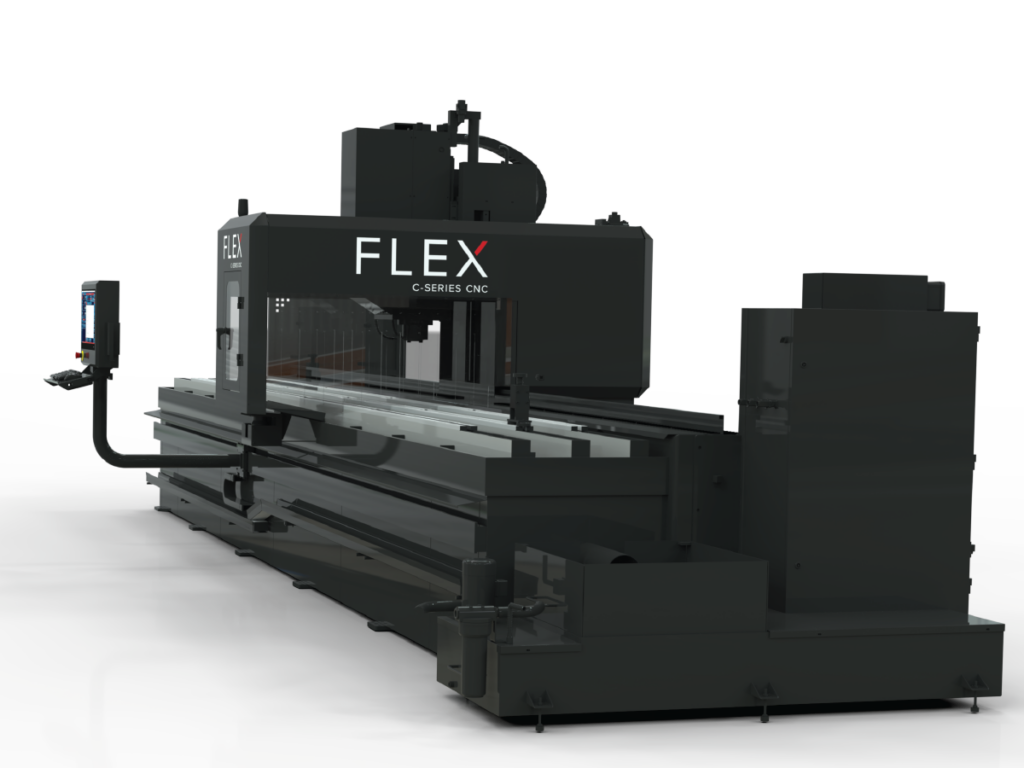

C-SERIES

C-20-02

XYZ: 240″ / 24″ / 17.5″

C-30-02

XYZ: 360″ / 24″ / 17.5″

C-40-02

XYZ: 480″ / 24″ / 17.5″

ADDITIONAL SIZES

Built to order

Machine lengths offered up to 60′

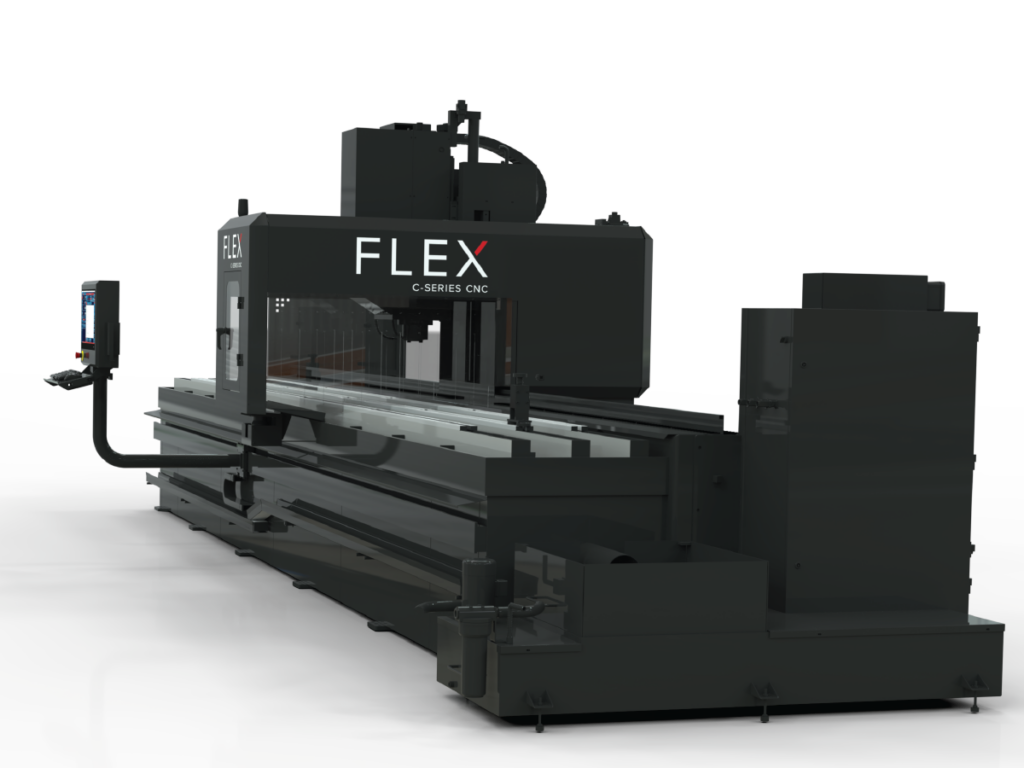

G-SERIES

G-20-06

XYZ: 240″ / 72″ / 19.5″

G-30-06

XYZ: 360″ / 72″ / 19.5″

G-40-06

XYZ: 480″ / 72″ / 19.5″

ADDITIONAL SIZES

Built to order

Machine lengths offered up to 60′

Why FlexCNC Stands out?

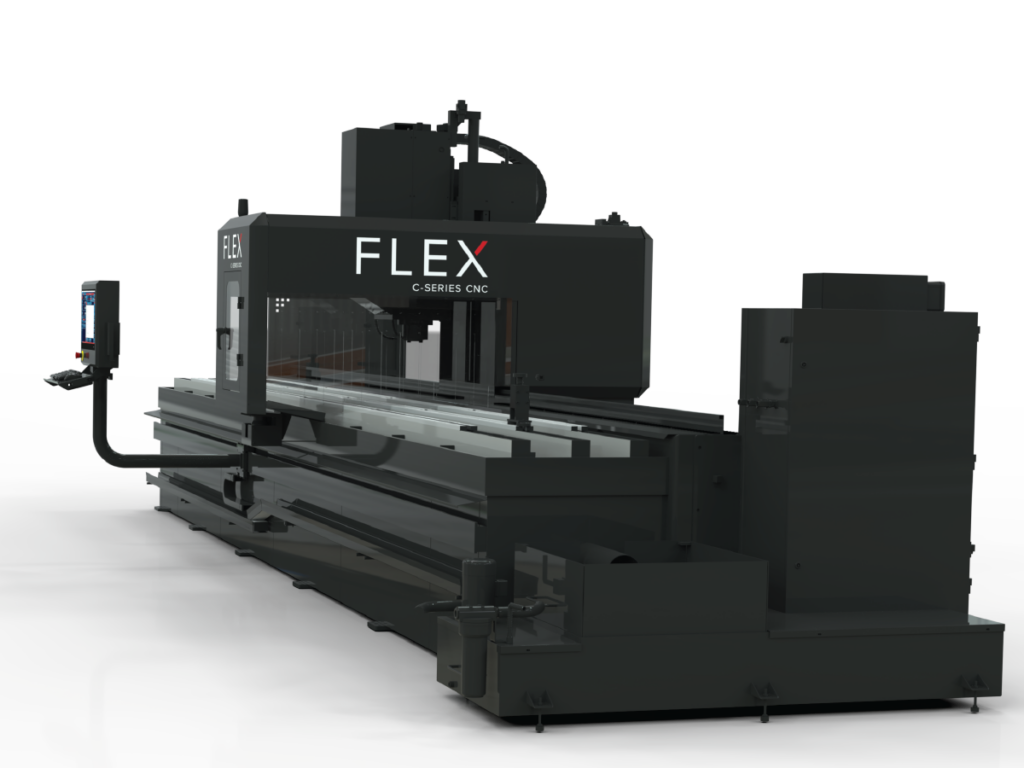

EXPANDED CAPABILITIES

No more limits on your machining potential. Our System is built for long, large parts that traditional machines simply can’t handle.

MAXIMIZE UPTIME WITH PENDULUM MODE:

You might not need 20′ bed, but imagine the possibilities with extra space

SAFETY FEATURES:

Advanced safety features like laser scanners, light curtains, and emergency stops ensure a secure work environment.

Features that Drive Results

Effortless Fixturing

T-slot rails and optional pneumatic/hydraulic work-holding make setups fast and flexible for any job.

Mobile Control System

Adjust settings and monitor progress from anywhere along the bed with smooth rail-mounted controls.

SEE HOW CUSTOMERS ARE USING THEIR MACHINES