- FlexCNC

- C-Series FlexCNC

- G-Series FlexCNC

- FlexCare+

- FlexBEAM CNC Structural Machining

- FlexBeam CNC

- FlexJet Waterjet Solution

- FL-Series

- F-Series

- FLX-Series

- FlexArm

- Tapping Arms

- Tables, Accs. & Tap Holders

- Taps & Accessories Store

- Die Grinding Arms

- Drilling Arms

FlexErgo

- Torque Reaction Arms

- Balance Arms

- Part Manipulator Arms

For service please call

1-800-837-2503 or

Request Service Here

FlexArm’s Tapping Solutions Help Launcher Deliver More Satellites to Orbit

Live Streaming Info is Below

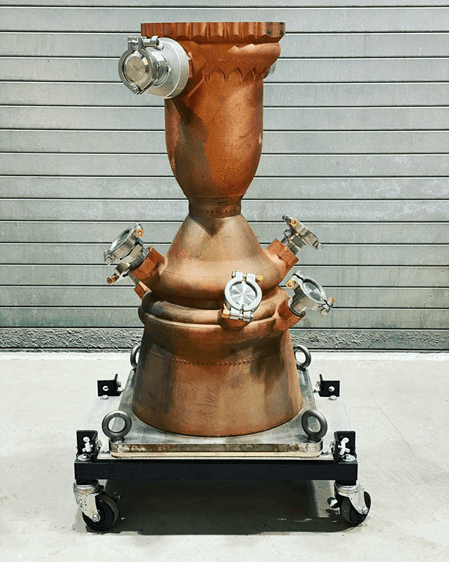

FlexArm has collaborated with Launcher, a startup based in New York City, to help them develop the world’s most efficient rocket for delivering small satellites to orbit. The key factor in Launcher’s achievement is their use of high-performance copper alloy for their E-2 Engines, which are 3D printed to reduce the amount of propellant required to reach orbit. This enables Launcher to deliver more satellite cargo per rocket than ever before.

To achieve this feat, Launcher required an effective tapping solution for their rocket launchers. The launchers have eight holes that require NPT taps ranging in size from 2″ to 1-1/4″. Initially, the Launcher team intended to tap the holes manually. However, they soon realized that keeping the metal chips out of the cooling chamber would not be feasible. Therefore, they sought out FlexArm for assistance in developing a solution chamber. Printing in a single piece reduces costs and enables the highest performance regenerative cooling design.

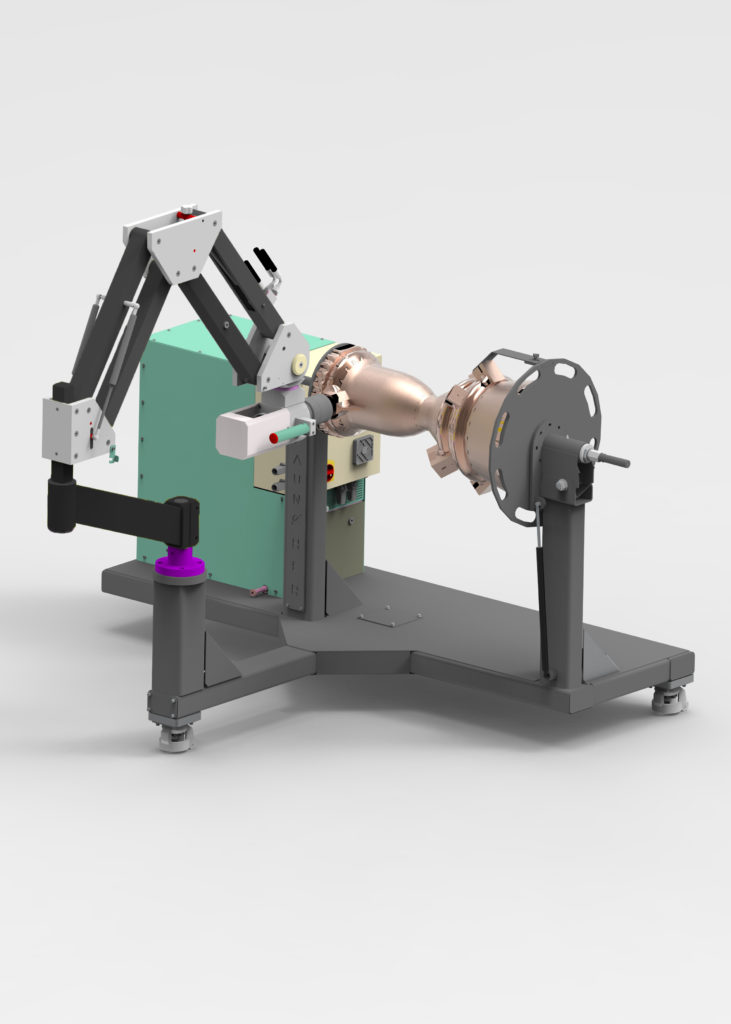

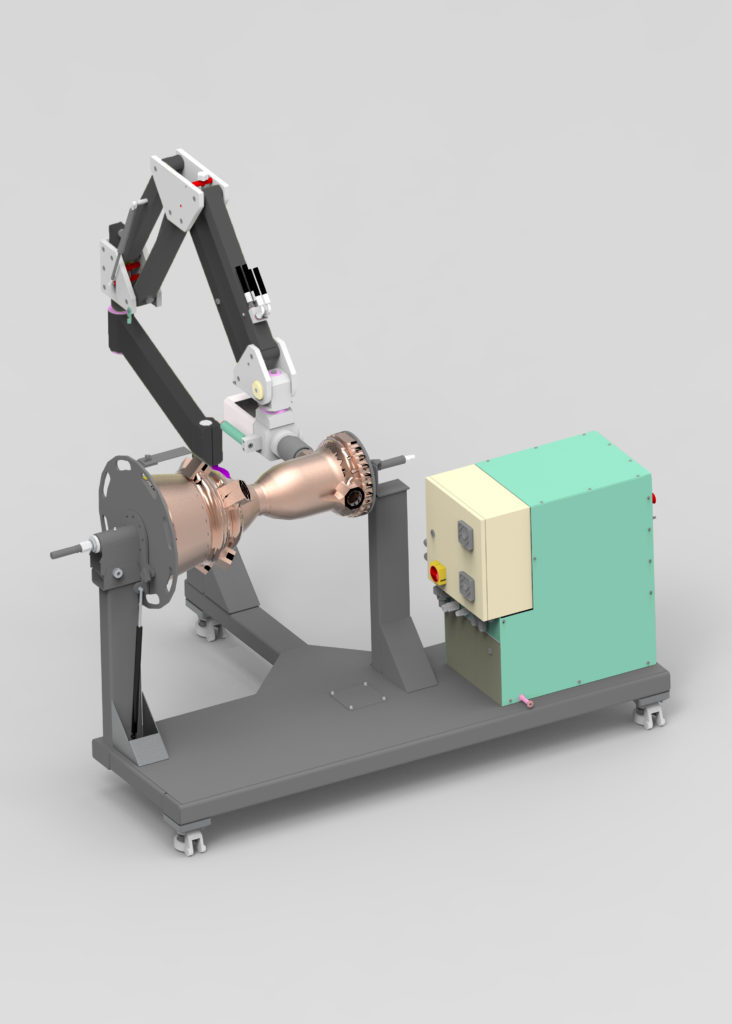

FlexArm provided a hydraulic arm with a multi-position head that could handle up to 811 ft/lbs of torque and do horizontal tapping. The engineering team at FlexArm developed a fixture that securely held the combustion chamber in place, ensuring correct alignment. The fixture held the part horizontally and rotated 360 degrees within it, enabling FlexArm to reach all eight holes easily with the multi-position head.

FlexArm created a prototype to test the fixture before tapping the actual part, ensuring the project’s success. This was crucial as it was Launcher’s first E-2 combustion chamber, and depth control was a key concern to avoid the threads going in too deep and the risk of cracking the rocket. The tapping process was conducted with air blown into the chamber to keep the metal chips out of the cooling chamber.

FlexArm is collaborating with OSG to provide the NPT taps required for this application. With their expertise, they helped select the following taps.

2″ – 11-1/2 NPT – EDP 1311000

1-1/2″-11-1/2 NPT – EDP 1310900

1-1/4″-11-1/2 NPT – EDP 1310808

7/8-14 UNF-2B – EDP 2939208

The partnership between Launcher and FlexArm emphasizes the significance of collaboration in achieving significant advancements in the space industry. With Launcher’s groundbreaking technology and FlexArm’s tapping solutions, the space industry is poised to experience further progress in the future.

In conclusion, FlexArm is proud to have been part of Launcher’s journey in pushing boundaries and achieving new heights in the space industry. With their focus on precision and durability, FlexArm has become a trusted partner for companies in various fields, including aerospace, automotive, defense, agriculture, and truck& trailer. Their partnership with Launcher in the space industry is just one example of how they continue to push the boundaries of innovation and collaboration. FlexArm’s proven track record of success makes them a reliable partner for any company looking to improve its tapping process.

Check out this exciting video of us tapping this rocket .Watch how the FlexArm performs

on this amazing 3D printed part.

Related Topics

Flex Machine Tools Partners with IGEMS to Elevate Waterjet Cutting Technology in North America

FlexJet powered by IGEMS CNC and CAD/CAM software is a collaboration between Ohio-based Flex Machine Tools and IGEMS of Sweden. The FlexJet will be integrated with the IGEMS CNC and its 5-axis waterjet cutting head known as the “Tilter”....

Read MoreSaving Money By Rescuing Damaged Threads

In the world of metalworking, precision and efficiency are paramount. Threading holes accurately and consistently is essential for ensuring the integrity and performance of manufactured components. However, even the most skilled machinists can encounter challenges, such as damaged or...

Read MoreFlex Machine Tools Launches New FlexJet FLX Waterjet Cutting System

Flex Machine Tools is excited to announce the launch of its newest waterjet cutting system, the FlexJet FLX. This innovative machine is designed to meet the demands of even the most discerning manufacturers, offering superior performance, service, and innovation....

Read More